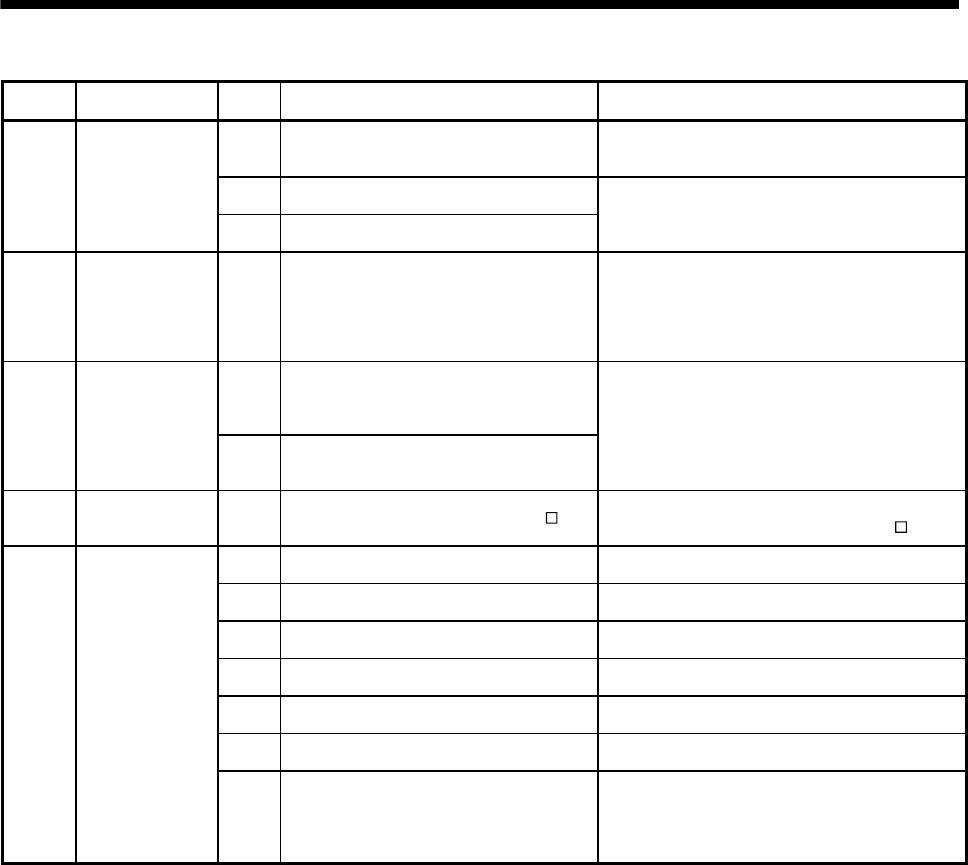

13 - 7

13. ALARM NUMBER

Alarm

No.

Content

Detail

No.

Cause of occurrence Procedure

56

Tandem drive

slave axis error

01

There is a servo alarm for the parallel drive

slave axis (including servo warning E6, E7,

E9).

Cancel the servo alarm. For details, refer to the

Servo Amplifier Instruction Manual on your servo

amplifier.

02

A communication error or a power outage

on the servo amplifier occurred.

Confirm that the connection to the servo amplifier

is intact. Reference system errors in the system

status code for details concerning communication

errors.

03

The tandem drive slave axis entered servo

ready off mode.

57

Exceeding of valid

width of tandem

drive deviation

compensation

error

01

The deviation between the master axis and

the slave axis exceeded the valid width

when home position return was performed

while in tandem drive mode.

(1) Adjust the mechanical deviation between the

master axis and the slave axis so that it is

within the valid width.

(2) Set the tandem drive home position signal

offset (parameter No.026C, 026D) to a correct

value.

58

Tandem drive

synchronous

alignment error

01

When a stop command is input during

calculation error correction performed for

turning on the servo, while in tandem drive

synchronous mode.

To correct the error between the master axis and

the slave axis, turn the servo off and then on to

perform synchronization again.

02

In tandem drive synchronous mode, the

start operation is performed without

completion of synchronization.

5B

Using other axes

start data

01

Other axes start data is being used (the

other axes start notice signal (OSOP ) is

on).

Check the other axes start data is not being used

(the other axes start notice signal (OSOP

) is off).

5C

Pass position

interrupt error

01

The setting to the start number of the pass

interrupt condition is out of range.

Check the start number setting of the pass

interrupt condition.

02

The setting to the end number of the pass

interrupt condition is out of range.

Check the end number setting of the pass

interrupt condition.

03

The start number of the pass interrupt

condition exceeds the end number.

Check the start number setting and the end

number setting of the pass interrupt condition.

04

The setting of the pass interrupt condition

is out of range.

Check the pass interrupt condition setting.

05

The specified pass interrupt condition is

used for other axes.

Do not overlap the pass interrupt condition

numbers for each axis.

06

The operation is started during the pass

position output interrupt.

Do not start the operation until the pass position

output interruption is completed.

07

During the pass position output interrupt

cancel signal (PPISTP) is on, the operation

is started with setting valid to the pass

position specification for auxiliary

command of point table.

Start the operation after turning off the pass

position output interrupt cancel signal (PPISTP).