6 - 113

6. APPLICATION FUNCTIONS

POINT

• The mark detection data table allocates continuous latch data storage area

automatically from the lowest axis to the highest axis.

• When the current feedback position set in mark detection data settings is

specified in command units, the fraction that comes about when converting

from pulse units is round down then stored.

• The lower 32 bits of data are latched for data in pulse units that exceeds 32

bits.

API LIBRARY

• Use the sscGetMarkDetectionData function to get mark detection data (mark

detection edge data

, mark detection positioning data ).

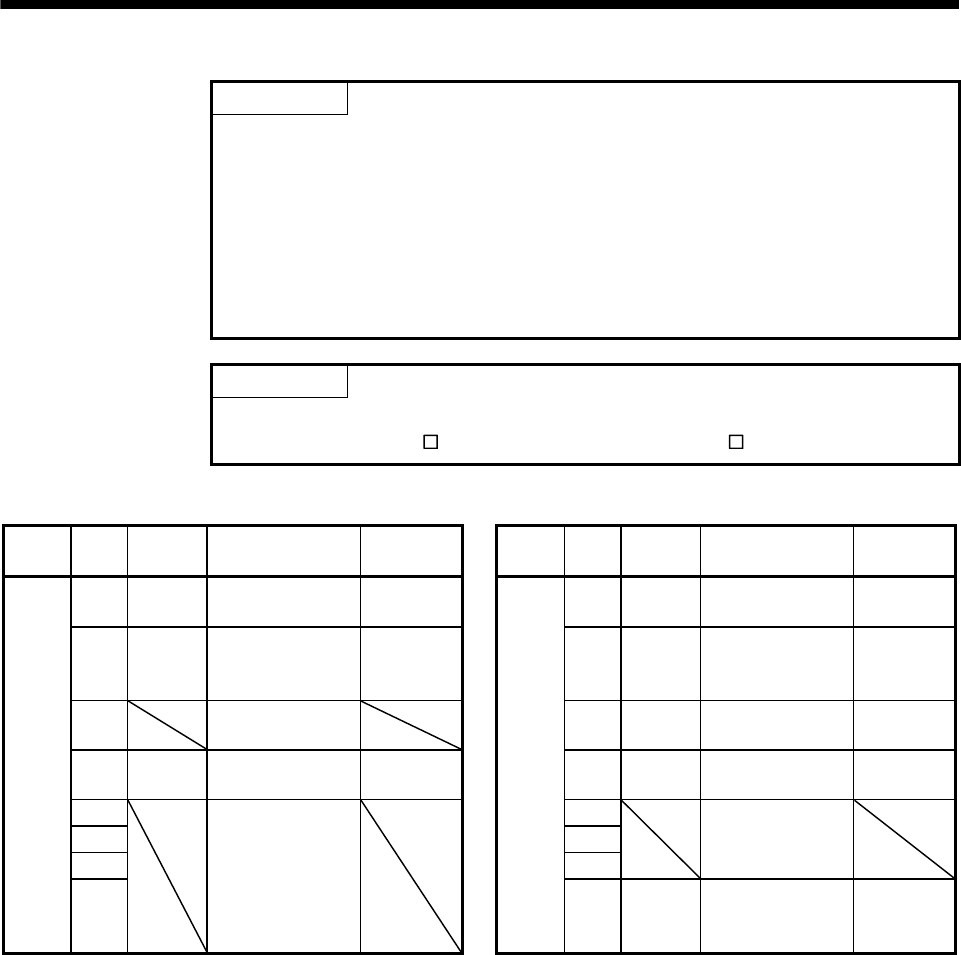

(5) Axis command/status bit

Address Bit Symbol Signal name

When in

tandem drive

Address Bit Symbol Signal name

When in

tandem drive

1008

0 GAIN

Gain switching

command

Each axis

1068

0 GAINO

During gain

switching

Each axis

1 FCLS

Fully closed loop

control change

command

Each axis

1 FCLSO

Fully closed loop

control changing

Each axis

2

Reserved

2 TLSO

Selecting torque

limit

Each axis

3 CPC

PID control

command

Each axis

3 SPC During PID control Each axis

4

Reserved

4

Reserved 5

5

6

6

7

7 PRSMO

During continuous

operation to torque

control

Not

supported