6 - 61

6. APPLICATION FUNCTIONS

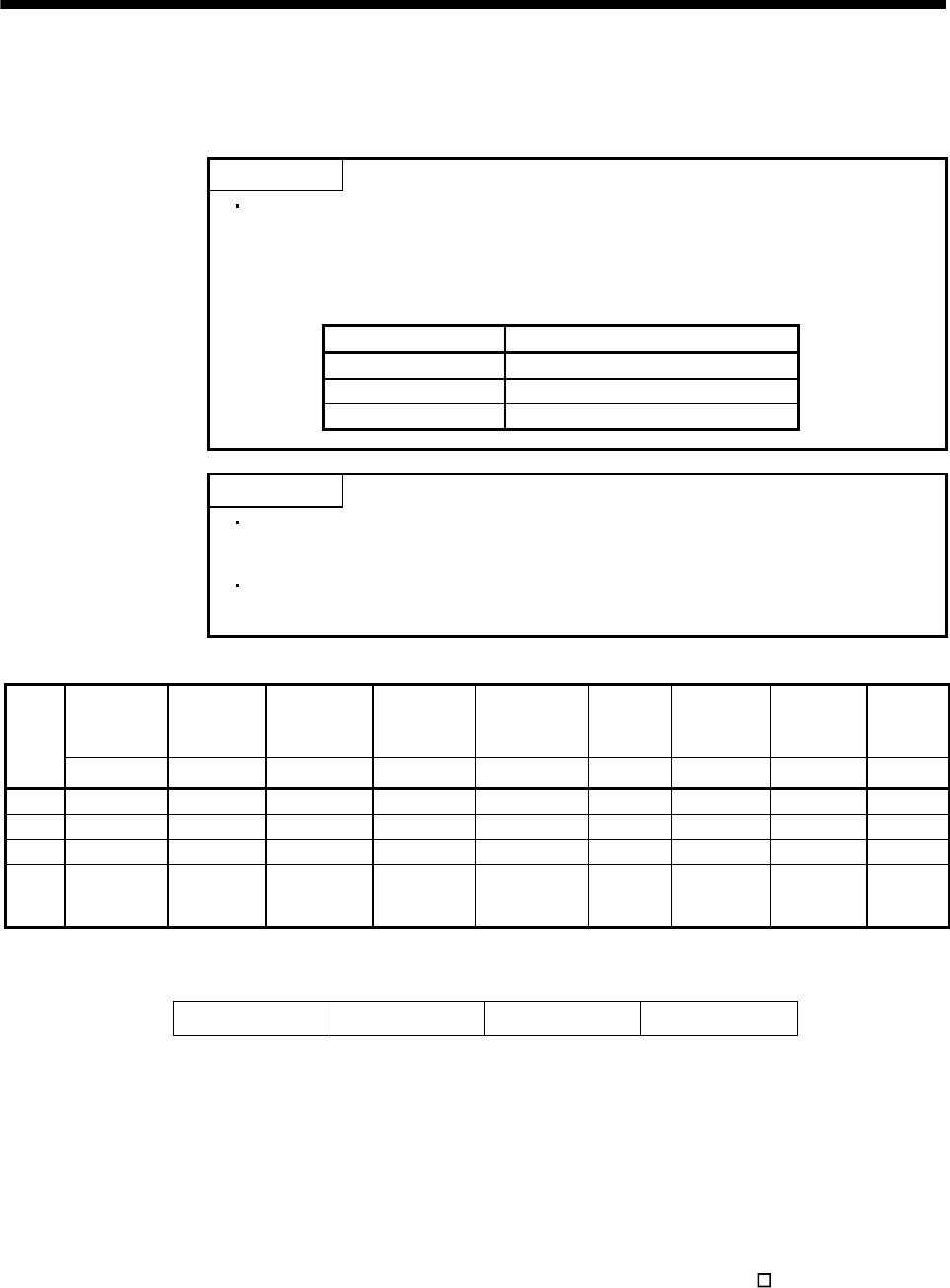

(1) Point table

Set the other axes start data No. for the other axes start specification.

POINT

The setting range of the other axes start data No. differs depending on the

control cycle. A maximum of 1 to 32 can be set. When the setting is out of the

range of the valid other axes start data No., it causes a point table setting

error (operation alarm 25, detail 09).

Control cycle Valid other axes start data No.

0.88ms 1 to 32

0.44ms 1 to 16

0.22ms 1 to 8

API LIBRARY

Use the sscSetPointDataEx/sscCheckPointDataEx functions to set/get point

table.

For a detailed procedure for other axes start, refer to the sample programs

(InterruptOas/PollingOas/OasDigitalOutput) contained on the utility software.

POINT

Position data

[Command

unit]

Feed speed

[Speed unit]

Acceleration

time constant

[ms]

Deceleration

time constant

[ms]

Dwell/predwell

[ms]

Auxiliary

command

Other axes

start

specification

S-curve ratio

[%]

Reserved

4 bytes 4 bytes 2 bytes 2 bytes 2 bytes 2 bytes 4 bytes 1 byte 11 bytes

0000 2000 2000 20 30 0 0000h 00000000h 100 0

0001 2000 3000 30 50 0 0000h 00000000h 100 0

0002 1000 1000 20 30 0 0000h 00000000h 100 0

: : : : : : : : : :

(a) Other axes start specification

0

Reserved Reserved

Other axes start

specification 2

Other axes start

specification 1

1624

8

Bit 31

• Other axes start specification 1 and 2

0 : Other axes start specification invalid

1 to 32: Other axes start data No.

Example) Set 00000401h to set 1 and 4 for the other axes start specification 1 and 2, respectively.

1) Cause of alarm

• When the other axes start data set in the other axes start specification at point switching or the start

of operation is being used (when the other axes start notice signal (OSOP

) is on), using other

axes start data (operation alarm 5B, detail 01) occurs and operation is terminated.

• If the setting of the other axes start specification is incorrect, it causes a point table setting error

(operation alarm 25, detail 09) and operation is stopped.