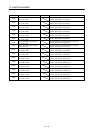

13 - 6

13. ALARM NUMBER

Alarm

No.

Content

Detail

No.

Cause of occurrence Procedure

40

Linear

interpolation start

up error

01

Axes that have been set to something

besides linear interpolation mode (LIP) are

included in the same group.

Designate all of the axes in the group as linear

interpolation mode (LIP).

02

There are 5 or more axes in the group

formation.

Set the group formation to a maximum of 4 axes.

03

Start operation was performed for linear

interpolation with the invalid linear

interpolation group number.

Reexamine the linear interpolation group

(parameter No.0260). Refer to Section 5.4 linear

interpolation for further details concerning valid

group number.

04

The number of points defined for axes in

the group is different.

Set the same number of points for all axes.

05

The speed unit for the primary axis

(parameter No.0200) is defined to be r/min.

Change the speed units.

41

Linear

interpolation point

data error

01

The movement amount in the group

exceeds the maximum value "999999999".

Set it to the correct data.

02

With excessive speed processing

(parameter No.0261) set to "1: alarm stop",

the group formation axis exceeds the

speed limit.

Reexamine feed speed and speed limit values.

42

Can't start linear

interpolation

auxiliary axis error

01 The auxiliary axis is in operation.

Perform start operation for linear interpolation

after making sure all axes in the group are

stopped.

02 The auxiliary axis has an alarm set.

Remove the cause for the alarm on the auxiliary

axis.

43

Interference

check axis setting

error

01

The axis is set up as the interference

check axis.

Set it to the correct data.

02

The axis in the same linear interpolation

group as the axis is set up as the

interference check axis.

44

Command error in

interference area

01

Commanded to move into interference

area.

Perform a commanded to move out of the

interference area.

45

Entering

interference area

error

01 Entered interference area during operation.

(1) Confirm that the parameter settings related to

interference check are correct.

(2) Change the operation pattern so that the

interference area is not entered.

4D

Other axes start

setting error

01 The start condition setting is erroneous.

Set correct data.

02 The operation setting is erroneous.

50

Tandem drive

mode change

error

01

Drive mode change was attempted while

tandem drive axis mode toggling was

prohibited.

Only attempt to change drive mode when change

conditions are satisfied.

Refer to Section 8.1.3.

51

While in tandem

drive non-

synchronous

mode

01

Home position return, automatic operation,

or linear interpolation operation was

attempted while in non-synchronous micro

adjustment mode of tandem drive axes.

Perform home position return, automatic operation

as well as linear interpolation operation while in

synchronous mode.

52

Tandem drive

axis setting error

01

A home position return method other than

dog method, dog cradle method, data set

method, scale home position signal

detection method, or dog front end method

was attempted for home position return

while in tandem drive axis mode.

Set the home position return option 1 to one of the

return to home position methods listed to the left.

02

A second axis is not set for the tandem

drive axis group. Or 3 or more axes are set

up with the same tandem drive group

number.

Set up the tandem drive axis group number in

pairs.

53

Tandem drive

excessive

deviation

01

The deviation between the master axis and

slave axis for tandem drive axes exceeds

the tandem drive excessive deviation width

of the parameter.

Make adjustments so that the deviation between

the master axis and slave axis is reduced. And

reexamine excessive deviation width and delay of

start detection for excessive deviation, defined in

the parameters.

54

Tandem drive

synchronous

alignment valid

width error

01

When deviation exceeds the synchronous

alignment valid width during calculation

error correction performed for servo on,

while in tandem drive synchronous mode.

Reexamine the parameter synchronous alignment

valid width. As the home position return is

incomplete (home position return request (ZREQ)

is ON), execute home position return again.

55

Tandem drive

while performing

synchronization

01

When start of operation is executed during

calculation error correction performed for

turning on of the servo, while in tandem

drive synchronous mode.

Do not perform start up while the "synchronizing"

signal (SYEO

) is on.