Configuration and Use Manual 151

Menu Flowcharts – Model 2400S DP Transmitters

Menus Display CodesBus ParametersDiagrams

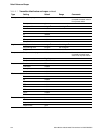

Figure C-2 ProLink II configuration menu

Flow

· Flow direction

·Flow damp

·Flow cal

· Mass flow cutoff

· Mass flow units

· Vol flow cutoff

(1)

· Vol flow units

(1)

· Vol flow type

· Std gas vol flow cutoff

(2)

· Std gas vol flow units

(2)

· Std gas density

(2)

Gas wizard

(2)

· Mass factor

·Dens factor

· Vol factor

Density

· Density units

· Density damping

· Slug high limit

· Slug low limit

· Slug duration

· Low density cutoff

·K1

·K2

·FD

·D1

·D2

· Temp coeff (DT)

Temperature

· Temp units

· Temp cal factor

· Temp damping

· External temperature

Pressure

·Flow factor

· Dens factor

· Cal pressure

· Pressure units

· External pressure

ProLink >

Configuration

continued

Sensor

·Sensor s/n

· Sensor model num

·Sensor matl

·Liner matl

·Flange

Sensor Limits

(3)

Mass flow

· Lower sensor limit

· Upper sensor limit

·Min span

Volume flow

· Lower sensor limit

· Upper sensor limit

·Min span

Density

· Lower sensor limit

· Upper sensor limit

·Min span

Temperature

· Lower sensor limit

· Upper sensor limit

·Min span

T Series

· FTG

· FFQ

·DTG

·DFQ1

·DFQ2

·K3

·D3

·D4

·K4

Device

·Tag

·Date

· Descriptor

·Message

· Floating pt ordering

· Add comm resp delay

· Transmitter serial #

Digital comm settings

· Fault setting

· Modbus address

· Disable Modbus ASCII

· Enable IrDA comm

· Enable write protect IrDA

port

I&M functions

(4)

·Tag

·Tag location

Last measured value timeout

Restore factory configuration

(4)

(1) Displayed only if Vol Flow Type is set to Liquid Volume.

(2) Displayed only if Vol Flow Type is set to Standard Gas Volume.

(3) All values on this panel are read-only, and are displayed only for informational purposes.

(4) Requires ProLink II v2.6 or later.