Teledyne API M100E Analyzer Operation Manual Getting Started

35

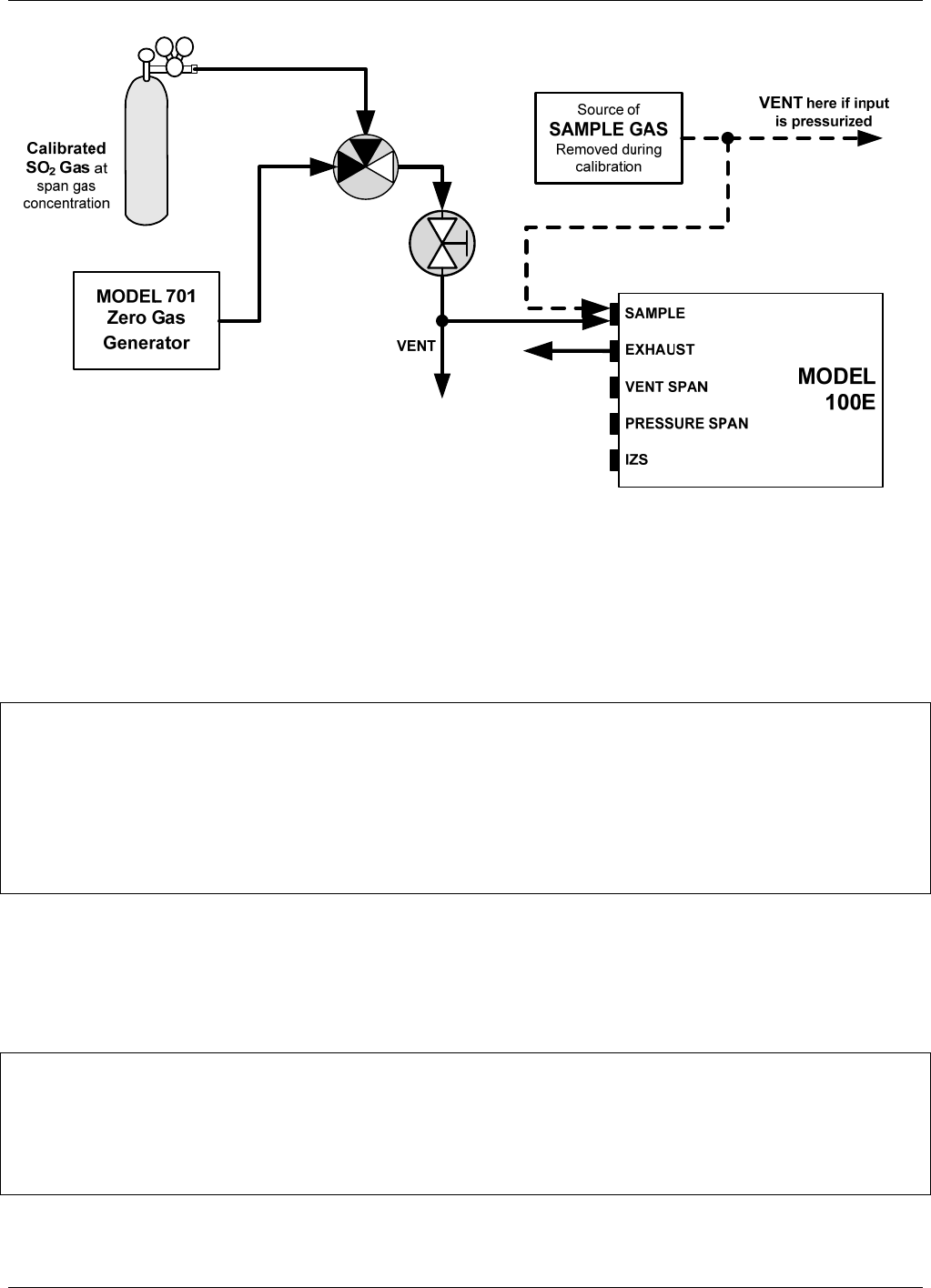

Figure 3-9: Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator

3.4.2.1. SAMPLE GAS SOURCE

Attach a ¼” sample inlet line to the sample inlet port.

The SAMPLE input line should not be more than 2 meters long.

NOTE

Ideally the maximum pressure of any gas at the sample inlet should equal ambient atmospheric pressure

and should NEVER exceed 1.5 in-hg above ambient pressure.

In applications where the sample gas is received from a pressurized manifold, a vent must be provided

to equalize the sample gas with ambient atmospheric pressure before it enters the analyzer. The vented

gas needs to be routed outside the immediate area or shelter surrounding the instrument.

Refer to Section 3.4.2.2 below for instructions on venting the Sample Gas Inlet.

3.4.2.2. CALIBRATION GAS SOURCES

The source of calibration gas is also attached to the SAMPLE inlet, but only when a calibration operation is

actually being performed. Refer to Chapter 8 for specific instructions on attaching span gas sources to the

M100E SO

2

Analyzer.

NOTE:

US EPA requirements state that zero air and span gases be supplied at twice the instrument’s specified

gas flow rate.

Therefore for the M100E zero and span gasses should be supplied to their respective inlets in excess of

1300 cc

3

/min (650 cc

3

/min. x 2).

04515F DCN6048