Teledyne API M100E Analyzer Operation Manual Theory Of Operation

229

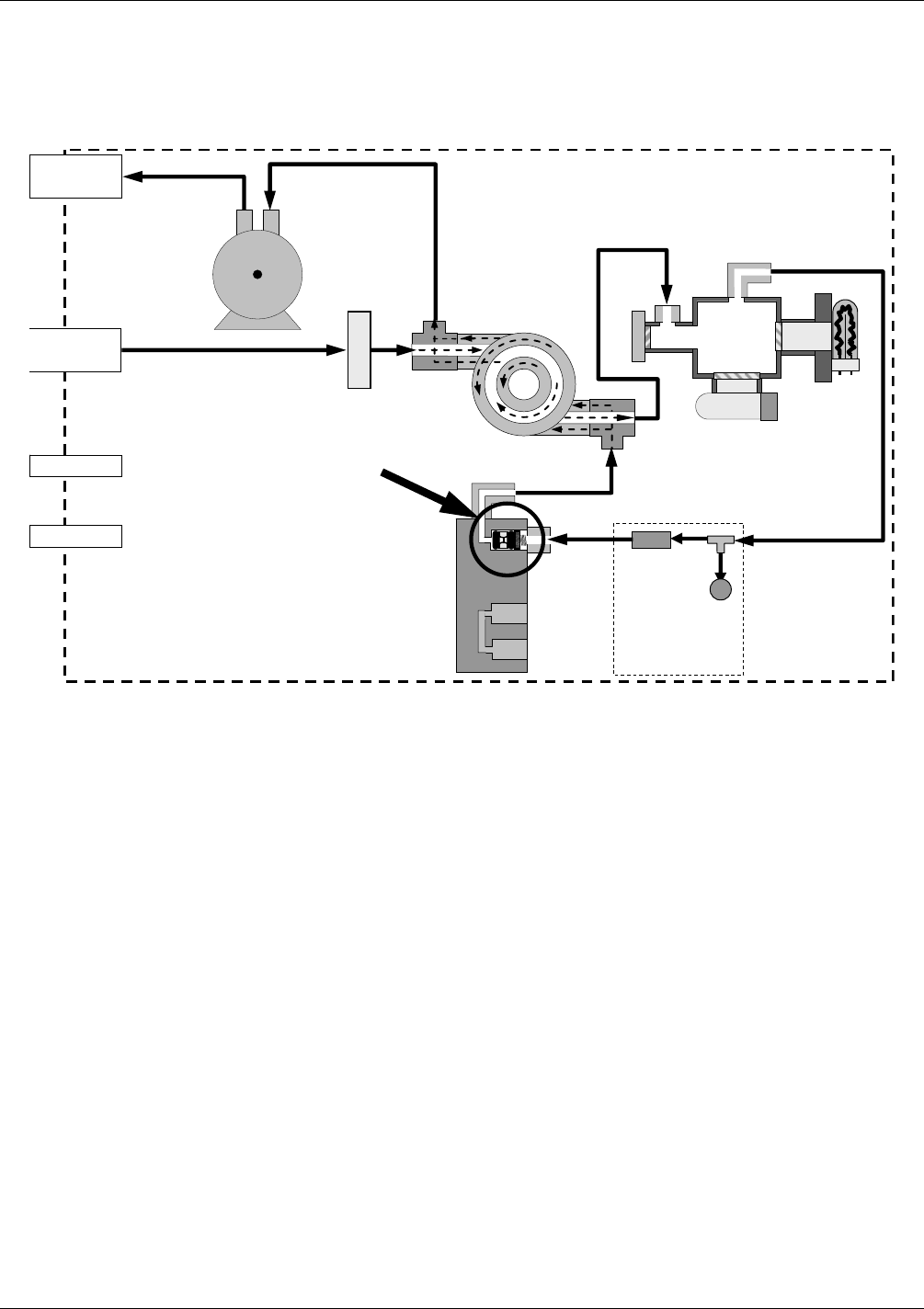

11.3.1. SAMPLE GAS FLOW

The Flow of gas through the M100E UV Fluorescence SO

2

Analyzer is created by a small internal pump that

pulls air though the instrument.

VACUUM MANIFOLD

FLOW

CONTROL

ASSY

EXHAUST TO OUTER

LAYER OF KICKER

SAMPLE GAS

INLET

SPAN GAS INLET

ZERO AIR INLET

SAMPLE FILTER

INSTRUMENT CHASSIS

EXHAUST GAS

OUTLET

KICKER EXHAUST

TO PUMP

HYDROCARBON

SCRUBBER

(KICKER)

UV

LAMP

PMT

SAMPLE

CHAMBER

FLOW

SENSOR

FLOW / PRESSURE

SENSOR PCA

SAMPLE

PRESSURE

SENSOR

PUMP

CRITICAL

FLOW

ORIFICE

Figure 11-7: Gas Flow and Location of Critical Flow Orifice

11.3.2. FLOW RATE CONTROL

The M100E uses a special flow control assembly located in the exhaust vacuum manifold (refer to Figure 11-7)

to maintain a constant flow rate of the sample gas through the instrument. This assembly consists of:

A critical flow orifice.

Two o-rings: Located just before and after the critical flow orifice, the o-rings seal the gap between the

walls of assembly housing and the critical flow orifice.

A spring: Applies mechanical force needed to form the seal between the o-rings, the critical flow orifice and

the assembly housing.

04515F DCN6048