Calibration Procedures Teledyne API M100E Analyzer Operation Manual

176

8.1.4. PERMEATION TUBES

Teledyne API offers an IZS option operating with permeation devices. The accuracy of these devices is about

±5%. Whereas this may be sufficient for quick, daily calibration checks, we strongly recommend using certified

SO

2

span gases for accurate calibration.

Note

Applications requiring US-EPA equivalency do not allow permeation devices to be used as sources of

span gas for calibration of the analyzer.

8.1.5. CALIBRATION GAS

All equipment used to produce calibration gases should be verified against standards of the National Institute for

Standards and Technology (NIST). To ensure NIST traceability, we recommend acquiring cylinders of working

gas that are certified to be traceable to NIST Standard Reference Materials (SRM). These are available from a

variety of commercial sources.

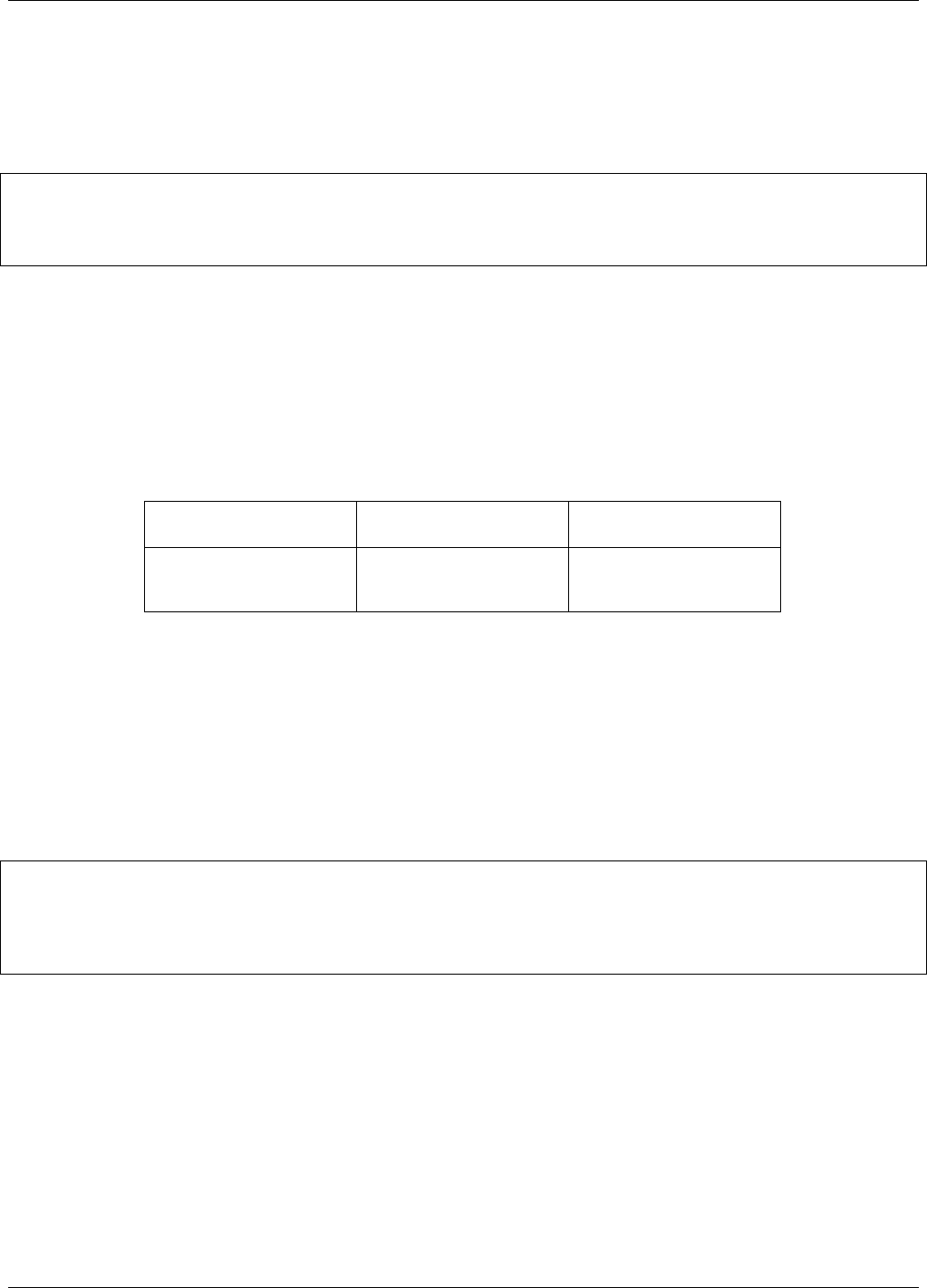

Table 8-1: NIST-SRM's Available for Traceability of SO

2

Calibration Gases

NIST-SRM

4

TYPE

NOMINAL

CONCENTRATION

1693a

1694a

1661a

Sulfur dioxide in N

2

Sulfur dioxide in N

2

Sulfur dioxide in N

2

50 ppm

100 ppm

500 ppm

8.1.6. DATA RECORDING DEVICES

A strip chart recorder, data acquisition system or digital data acquisition system should be used to record data

from the M100E’s serial or analog outputs. If analog readings are used, the response of the recording system

should be checked against a NIST traceable voltage source or meter. Data recording device should be capable

of bi-polar operation so that negative readings can be recorded. For electronic data recording, the M100E

provides an internal data acquisition system (iDAS), which is described in detail in Section 7.2.

Calibration a

nd Calibration Check

Pressing the ENTR key during the following procedure re-calculates the stored values for OFFSET and

SLOPE and alters the instrument’s calibration.

If you wish to perform a calibration CHECK, do not press ENTR and refer to Section 8.3.

04515F DCN6048