211

10.2. PREDICTIVE DIAGNOSTICS

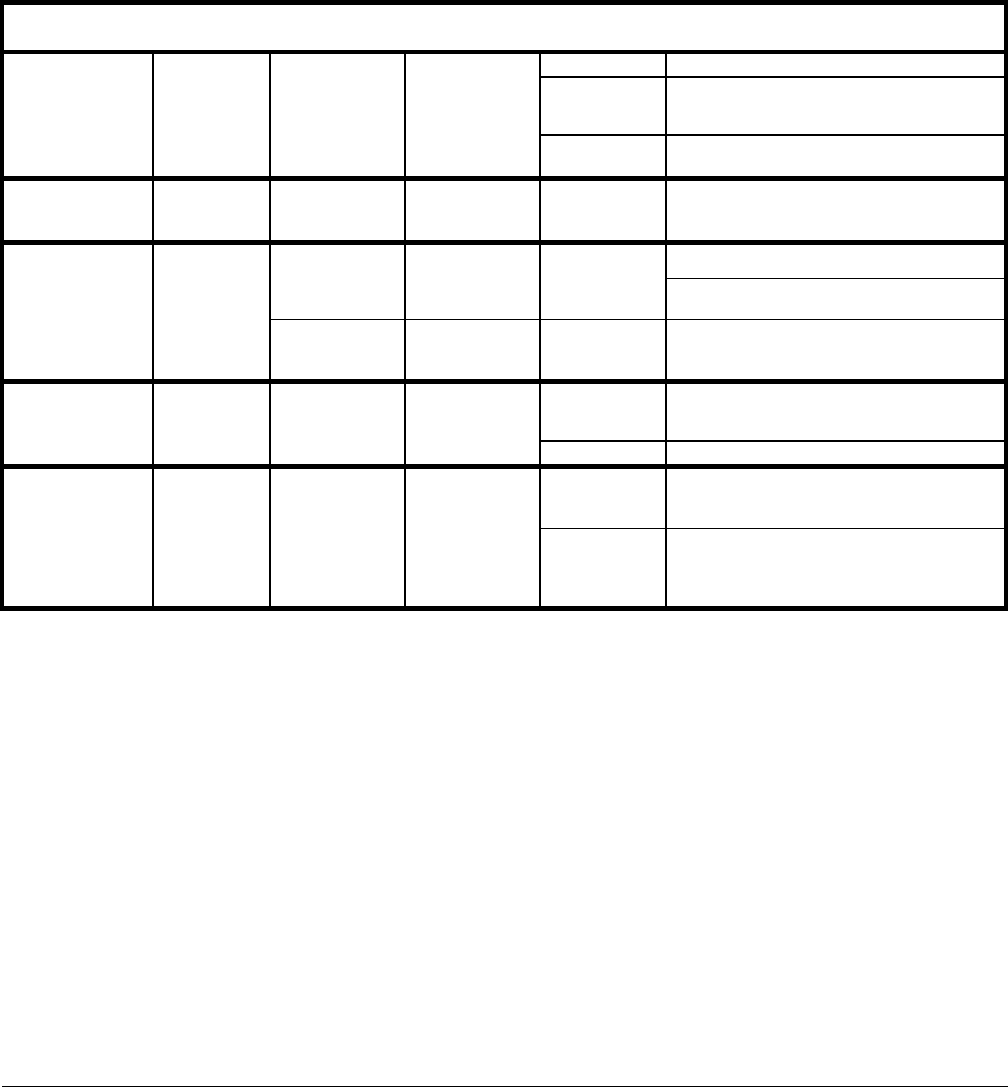

The analyzer’s test functions can be used to predict failures by looking at trends in their values (refer to Table

10-2) and by comparing them values recorded for them at the factory and recorded on the M100E Final Test and

Validation Data Form (Teledyne API P/N 04551) that was shipped with your analyzer.

A convenient way to record and track changes to these parameters is the internal data acquisition system

(iDAS). Also, APICOM control software can be used to download and record these data for review even from

remote locations (refer to Section 7.3.2.8 describes APICOM).

Table 10

-2:

Predictive Uses for Test Functions

BEHAVIOR

TEST FUNCTION

iDAS

FUNCTION

CONDITION

EXPECTED ACTUAL

INTERPRETATION

Fluctuating

Developing leak in pneumatic system

Slowly

increasing

Flow path is clogging up.

- Check critical flow orifice & sintered filter.

- Replace particulate filter

PRES SMPPRS sample gas

Constant within

atmospheric

changes

Slowly

decreasing

Developing leak in pneumatic system to

vacuum (developing valve failure)

DRK PMT DRKPMT

PMT output

when UV Lamp

shutter closed

Constant within

±20 of check-

out value

Significantly

increasing

PMT cooler failure

Shutter Failure

Change in instrument response

At span with

IZS option

installed

Constant

response from

day to day

Decreasing

over time

Degradation of IZS permeation tube

SO

2

Concentration

CONC1

Standard

configuration at

span

stable for

constant

concentration

Decreasing

over time

Drift of instrument response; UV Lamp

output is excessively low.

Slowly

Decreasing

Flow path is clogging up.

- Check critical flow orifice & sintered filter.

- Replace particulate filter

SAMP FL SMPFLW

Standard

Operation

Stable

Fluctuating

Leak in gas flow path.

Fluctuating or

Slowly

increasing

UV detector wearing out

UV source Filter developing pin holes

LAMP RATIO LAMPR

Standard

Operation

Stable and near

100%

Slowly

decreasing

UV detector wearing out

Opaque oxides building up on UV source

Filter

UV lamp aging

04515F DCN6048