Model GFC7000E Instruction Manual APPENDIX A-2: Setup Variables For Serial I/O, Revision

E.0APPENDIX A-3: Warnings and Test Functions, Revision E.0

045840110 Rev B.3 236

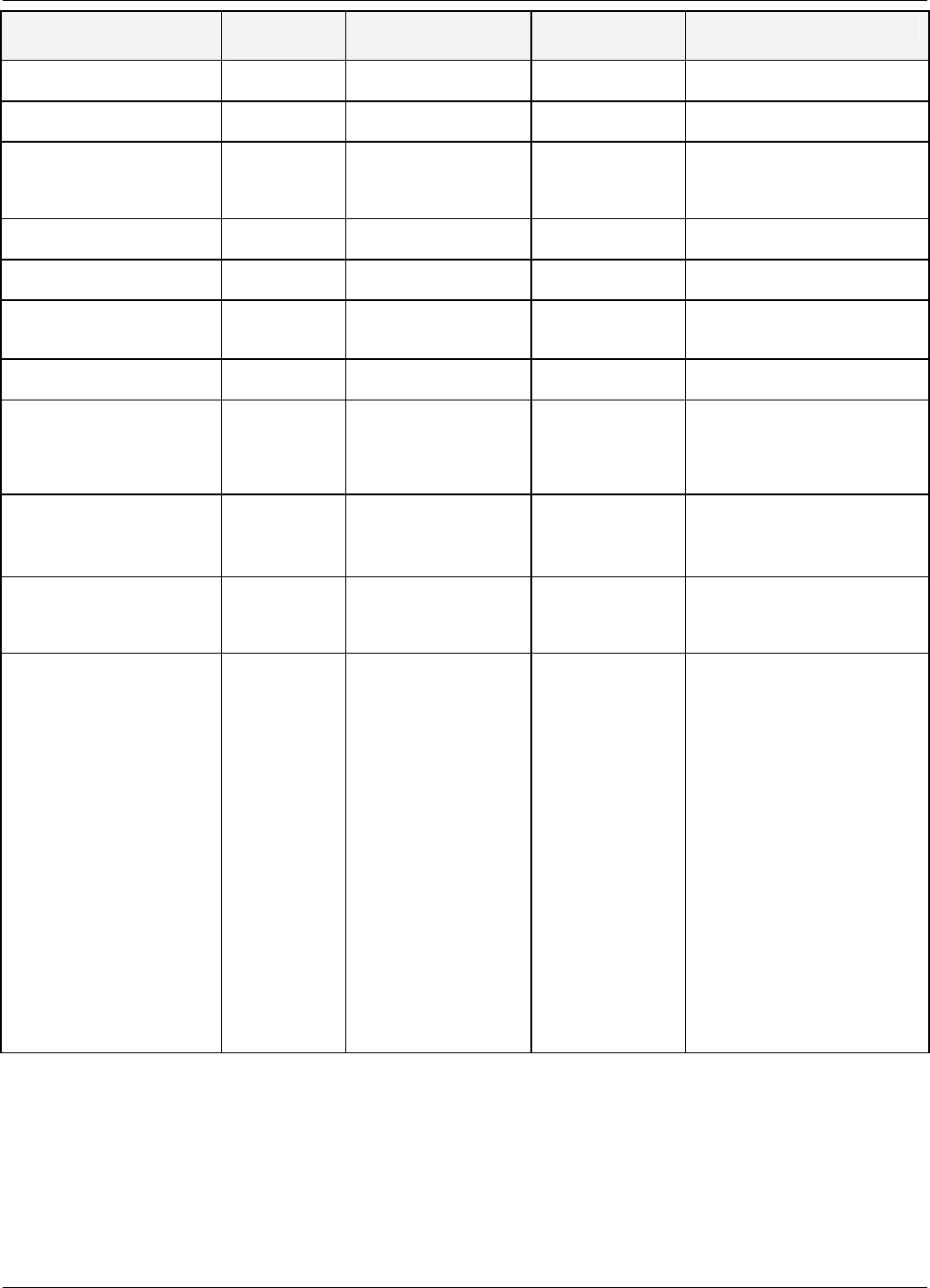

SETUP VARIABLE NUMERIC

UNITS

DEFAULT VALUE VALUE RANGE

DESCRIPTION

BENCH_DERIV — 2 0–100 Optical bench temperature

PID derivative coefficient.

WHEEL_CYCLE Seconds 4, 2

4

0.5–30 Wheel temperature control

cycle period.

WHEEL_PROP 1/ºC 1 0–100 Wheel temperature PID

proportional coefficient.

Proportional band is the

reciprocal of this setting.

WHEEL_INTEG — 0.135, 0.035

4

0–100 Wheel temperature PID

integral coefficient.

WHEEL_DERIV — 2 0–100 Wheel temperature PID

derivative coefficient.

TPC_ENABLE — ON OFF, ON ON enables temperature/

pressure compensation; OFF

disables it.

CONC_LIN_ENABLE — ON OFF, ON ON enables concentration

linearization; OFF disables it.

SERIAL_NUMBER — “00000000 ”

0

Any character in

the allowed

character set. Up

to 100 characters

long.

Unique serial number for

instrument.

DISP_INTENSITY — HIGH

0

HIGH,

MED,

LOW,

DIM

Front panel display intensity.

I2C_RESET_ENABLE — ON OFF, ON ON enables automatic reset

of the I

2

C bus in the event of

communication failures; OFF

disables automatic reset.

FACTORY_OPT BitFlag 0, 4

9

0–65535 Factory option flags. Add

values to combine flags.

1 = enable dilution factor

2 = zero/span valves

installed

4 = conc. alarms routed to

relays

8 = enable linearity

adjustment factor

16 = display units in

concentration field

32 = enable software-

controlled maintenance mode

64

3, 5

= span valve installed

128 = enable switch-

controlled maintenance mode

2048 = enable Internet

option

7

4096 = use “old” style

numeric data entry menus

when editing conc. table