Model GFC7000E Instruction Manual THEORY OF OPERATION

04584 Rev A1 164

10.3.3.2. IR Source

The light used to detect CO

2

in the sample chamber is generated by a element heated to

approximately 1100

o

C producing infrared radiation across a broad band. This radiation is optically

filtered after it has passed through the GFC Wheel and the sample chamber and just before it

reaches the photo-detector to eliminate all black body radiation and other extraneous IR emitted

by the various components of those components.

10.3.3.3. GFC Wheel

A synchronous AC motor turns the GFC wheel motor. For analyzers operating on 60Hz line power

this motor turns at 1800 rpm. For those operating on 50Hz line power the spin rate is 1500 rpm.

The actual spin rate is unimportant within a large rate since a phase lock loop circuit is used to

generate timing pulses for signal processing.

In order to accurately interpret the fluctuations of the IR beam after it has passed through the

sample gas, the GFC wheel several other timing signals are produced by other photo

emitters/detectors. These devices consist of a combination LED and detector mounted so that the

light emitted by the LED shines through the same mask on the GFC wheel that chops the IR

beam.

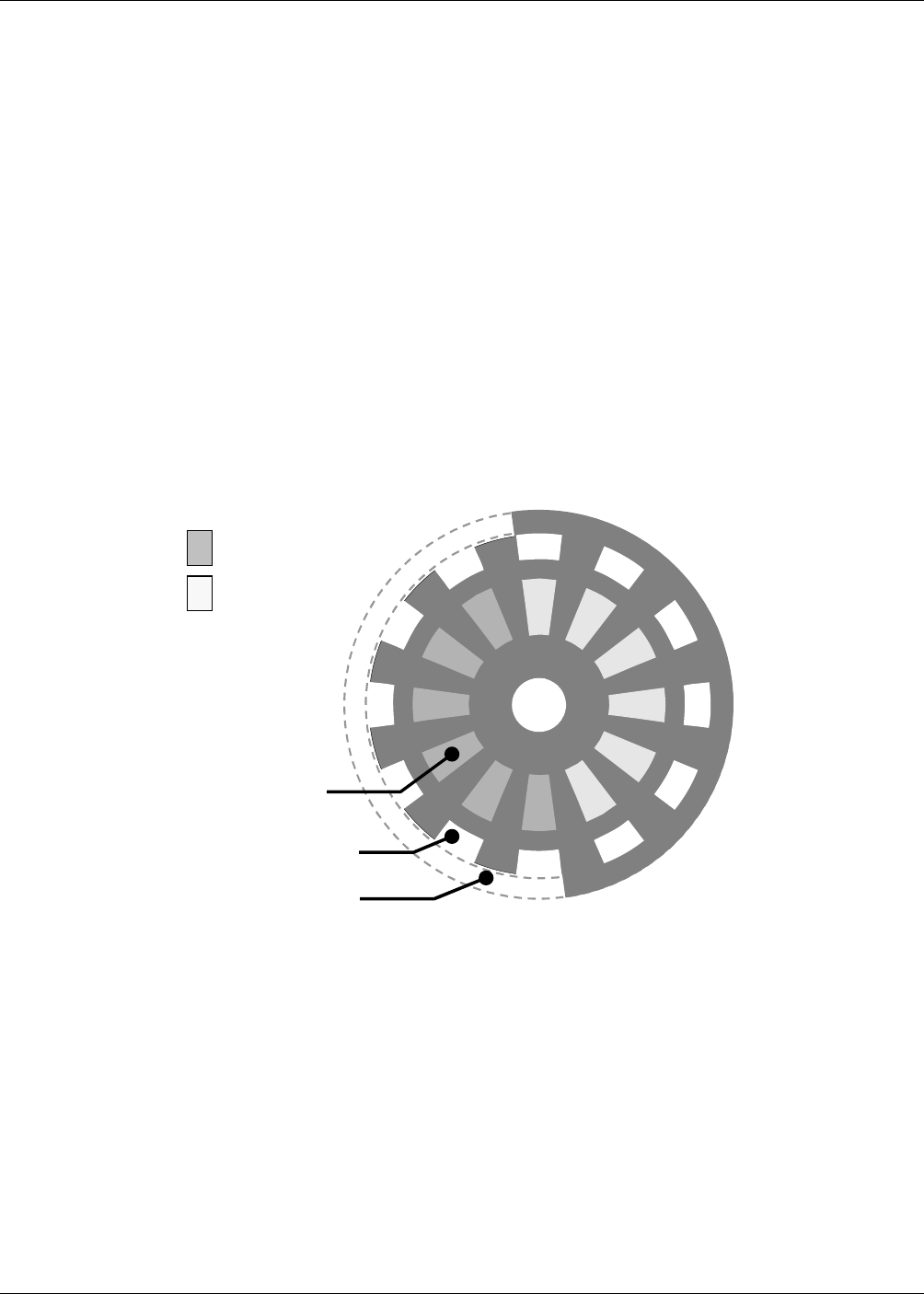

IR Detection Ring

Segment Sensor Ring

M/R Sensor Ring

KEY:

Detection Beam shining

through MEASUREMENT

side of GFC Wheel

Detection Beam shining

through REFERENCE

side of GFC Wheel

Figure 10-10: GFC Light Mask

M/R Sensor

The emitter/detector assembly that produces this signal shines through a portion of the mask that

allows light to pass for half of a full revolution of the wheel. The resulting light signal tells the

analyzer whether the IR beam is shining through the measurement or the reference side of the

GFC wheel.

Segment Sensor

This emitter/detector shines through a portion of the mask that is divided into the same number

of segments as the portion of the mask through which the IR beam passes. It is used by the