Model GFC7000E Instruction Manual THEORY OF OPERATION

04584 Rev A1 160

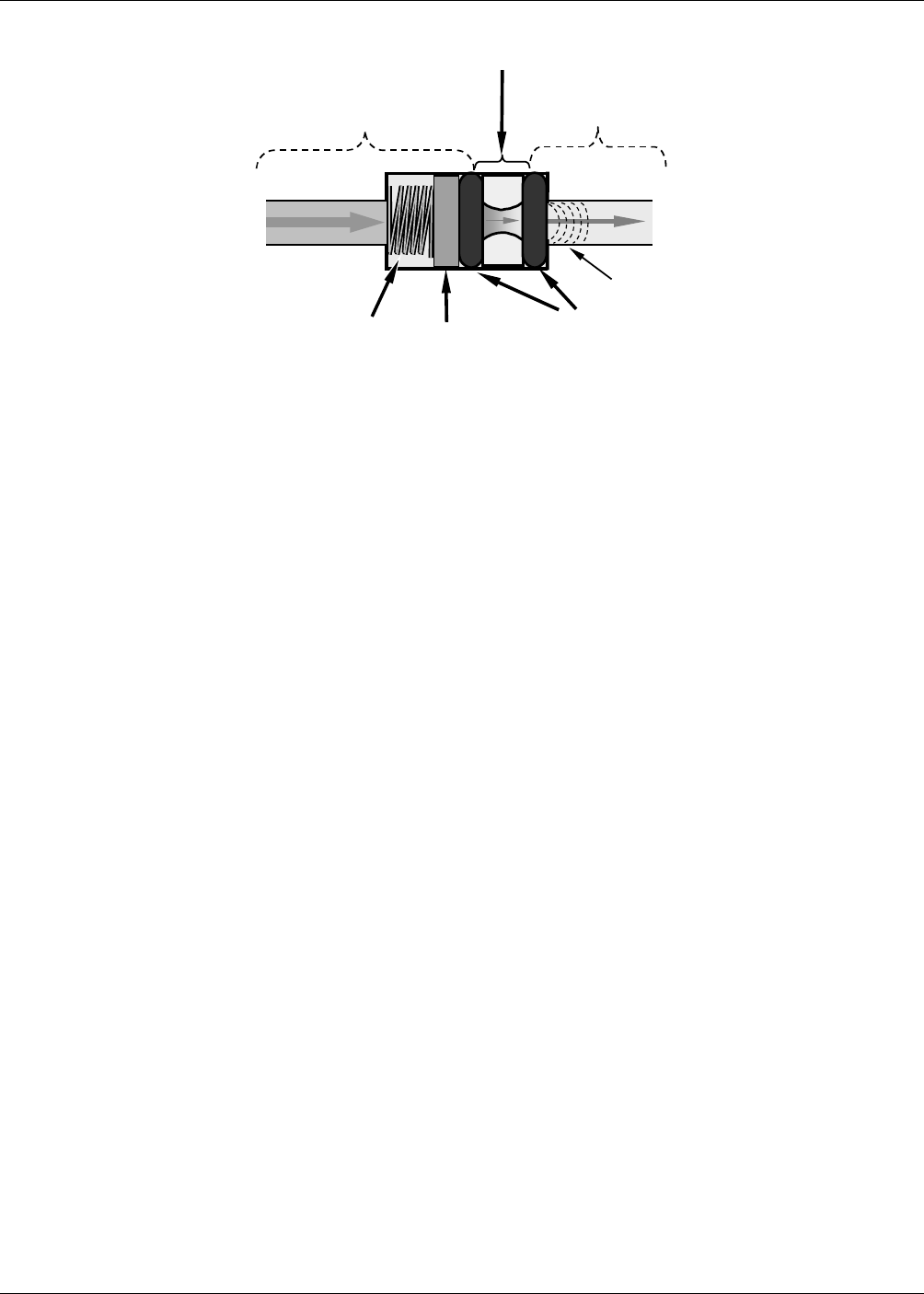

SPRING

O-RINGS

FILTER

CRITICAL

FLOW

ORIFICE

A

REA OF

LOW

PRESSURE

AREA OF

HIGH

PRESSURE

Sonic

Shockwave

Figure 10-8: Flow Control Assembly & Critical Flow Orifice

The actual flow rate of gas through the orifice (volume of gas per unit of time), depends on the

size and shape of the aperture in the orifice. The larger the hole, the more gas molecules, moving

at the speed of sound, pass through the orifice. Also, because the flow rate of gas through the

orifice is only related to the minimum 2:1 pressure differential and not absolute pressure:

• Pressure wave created by the pump’s action are filtered out.

• The flow rate of gas through the sample chamber will be the same regardless of whether

the analyzer is at the bottom of Death Valley or on top of Pikes Peak.

• The flow rate of the gas is also unaffected by degradations in pump efficiency due to age.

The critical flow orifice used in the Model GFC7000E is designed to provide a flow rate of 800

cm

3

/min.

10.2.1.2. Sample Pressure Sensor

An absolute value pressure transducer plumbed to the outlet of the sample chamber is used to

measure sample pressure. The output of the sensor is used to compensate the concentration

measurement for changes in air pressure. This sensor is mounted to a printed circuit board with

the sample flow sensor on the sample chamber; see following section and Figure 3-11.

10.2.1.3. Sample Flow Sensor

A thermal-mass flow sensor is used to measure the sample flow through the analyzer. The sensor

is calibrated at the factory with ambient air or N

2

, but can calibrated to operate with samples

consisting of other gases such as CO

2

, see Section 9.3.4. This sensor is mounted to a printed

circuit board with the Sample Pressure sensor on the sample chamber; see previous section and

Figure 3-11.