Model GFC7000E Instruction Manual TROUBLESHOOTING & REPAIR PROCEDURES

04584 Rev A1 192

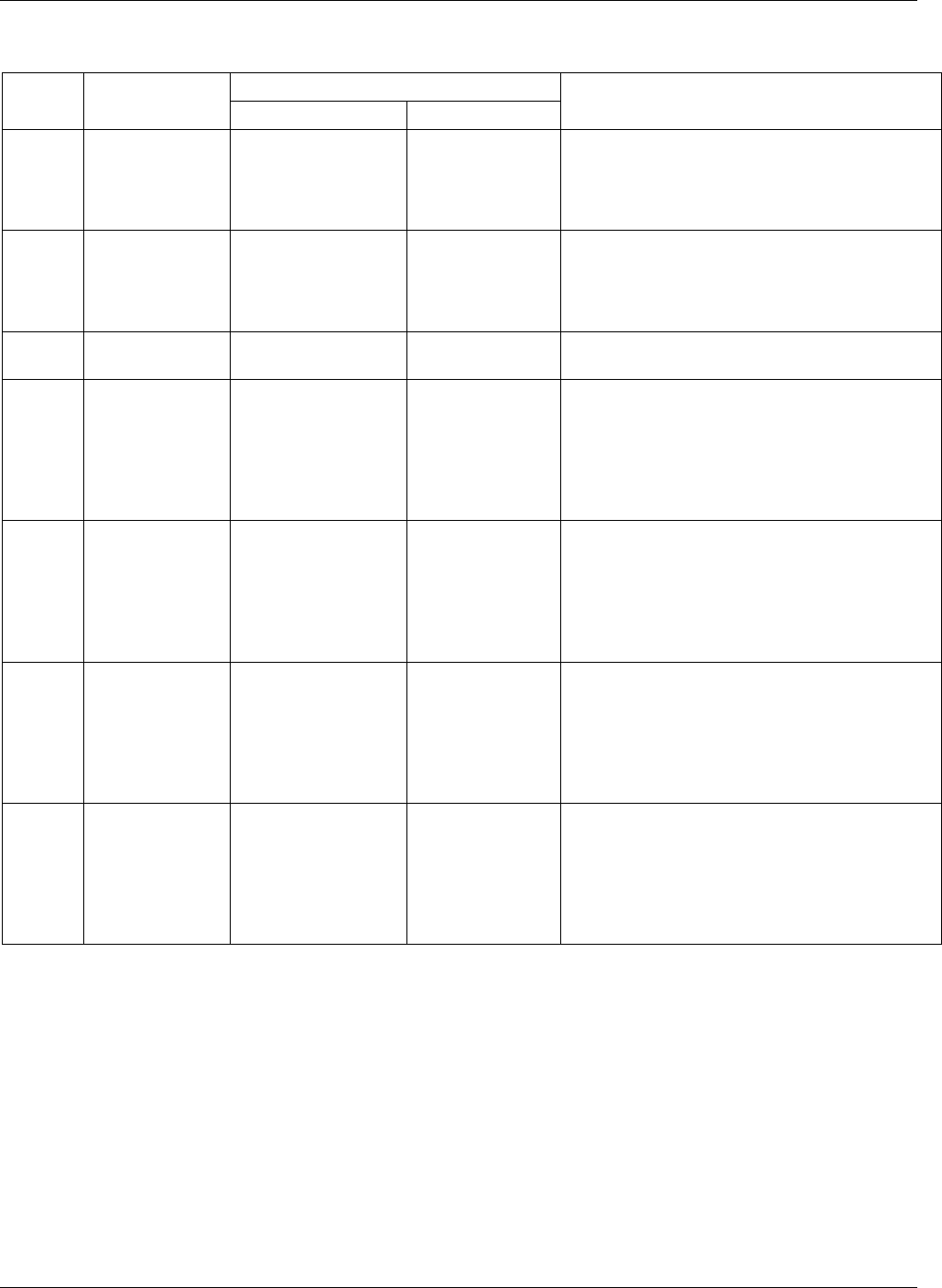

Table 11-5: Relay Board Status LED Failure Indications

SIGNAL I/O PARAMETER

LED FUNCTION

ACTIVATED BY VIEW RESULT

DIAGNOSTIC TECHNIQUE

D2

Yellow

WHEEL

HEATER

WHEEL_HEATER WHEEL_TEMP

Voltage displayed should change. If not:

Failed Heater

Faulty Temperature Sensor

Failed AC Relay

Faulty Connectors/Wiring

D3

Yellow

BENCH

HEATER

BENCH_HEATER BENCH_TEMP

Voltage displayed should change. If not:

Failed Heater

Faulty Temperature Sensor

Failed AC Relay

Faulty Connectors/Wiring

D4

Yellow

SPARE N/A N/A

N/A

D5

Green

SAMPLE/CAL

GAS VALVE

OPTION

CAL_VALVE N/A

Sample/Cal Valve should audibly change

states. If not:

Failed Valve

Failed Relay Drive IC on Relay Board

Failed Relay Board

Faulty +12 VDC Supply (PS2)

Faulty Connectors/Wiring

D6

Green

ZERO/SPAN

GAS VALVE

OPTION

SPAN_VALVE N/A

Zero/Span Valve should audibly change

states. If not:

Failed Valve

Failed Relay Drive IC on Relay Board

Failed Relay Board

Faulty +12 VDC Supply (PS2)

Faulty Connectors/Wiring

D7

Green

SHUTOFF

VALVE OPTION

SHUTOFF_VALVE

N/A

Shutoff Valve should audibly change

states. If not:

Failed Valve

Failed Relay Drive IC on Relay Board

Failed Relay Board

Faulty +12 VDC Supply (PS2)

Faulty Connectors/Wiring

D8

Green

IR SOURCE IR_SOURCE CO

2

_MEASURE

Voltage displayed should change. If not:

Failed IR Source

Faulty +12 VDC Supply (PS2)

Failed Relay Board

Failed IR Photo-Detector

Failed Sync/Demod Board

Faulty Connectors/Wiring

11.1.5. Gas Flow Problems

In general, flow problems can be divided into three categories:

1. Flow is too high

2. Flow is greater than zero, but is too low, and/or unstable

3. Flow is zero (no flow)

When troubleshooting flow problems, it is a good idea to first confirm that the actual flow and not

the analyzer’s flow sensor and software are in error, or the flow meter is in error. Use an