13 - 11

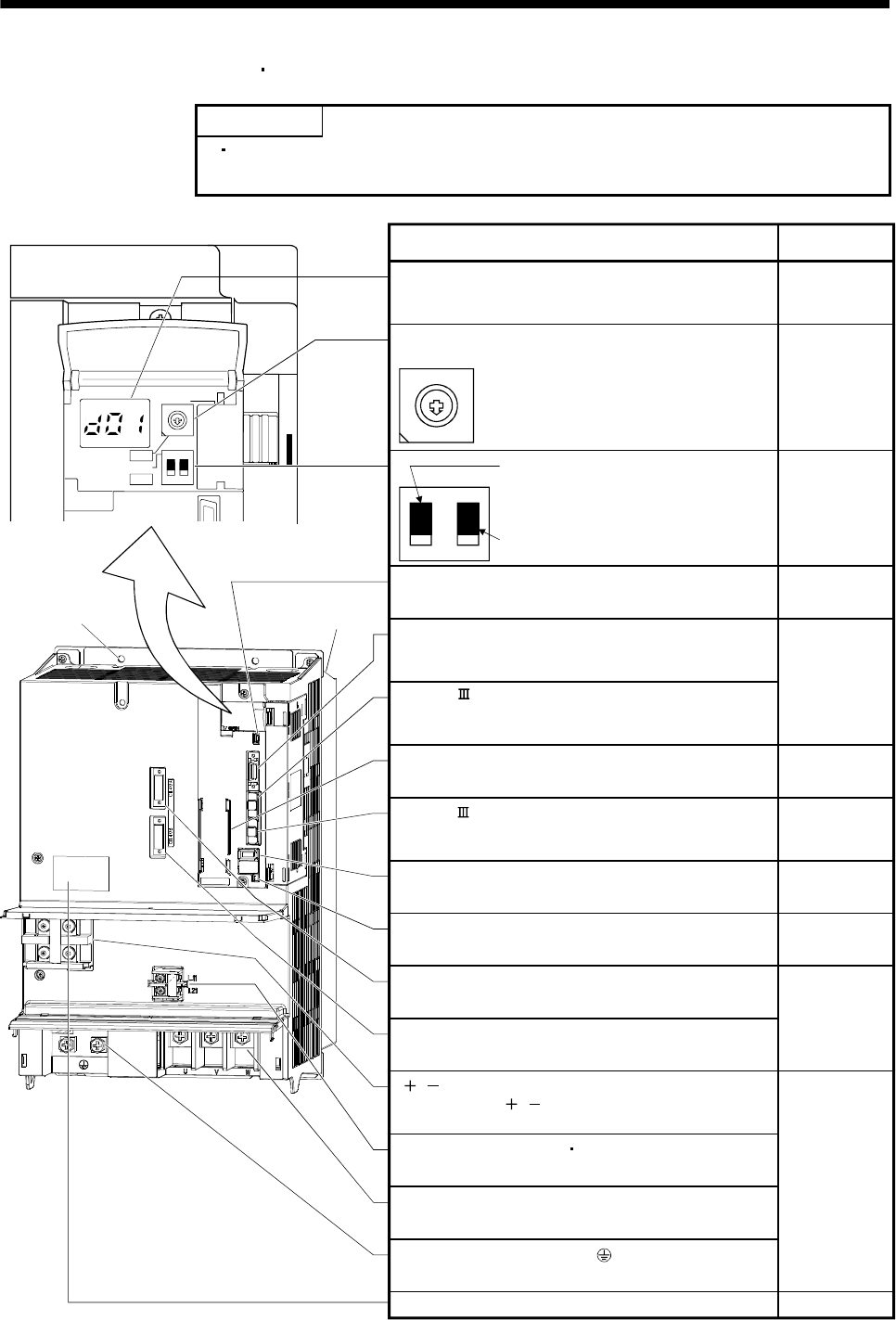

13. SERVO AMPLIFIERS WITH A LARGE CAPACITY (30k TO 55kW)

(2) Drive unit (MR-J3-DU30KB4

MR-J3-DU37KB4)

POINT

The servo amplifier is shown with the front cover opened. For removal of the

front cover, refer to section 13.1.7.

7

9

6

8

5

4

3

2

1

0

F

E

D

C

B

A

12

ON 4F

SW1

SW2

TEST

Cooling fan

Chapter 4

Section 3.2

Section 3.4

Section 11.8

Section 3.13

Section 3.13

Section 13.1.4

Section 3.4

Section 11.1

Section 11.9

Chapter 12

Section 3.2

Section 3.4

Section 12.3

Test operation select switch (SW2-1)

Used to perform the test operation mode

by using MR Configurator.

Spare (Be sure to set to the "Down"

position).

Rating plate

Section 13.3.2

SW2

SW1

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

12

Section 13.3.3

L L terminals (TE2)

Connect to the L L terminals of the converter unit

using the connection conductors supplied.

Control circuit terminal L11 L21 (TE3)

Supply control circuit power.

Motor power supply terminals (TE1)

Connect to U, V, W of the servo motor.

Display

The 3-digit, seven-segment LED shows the servo

status and alarm number.

Used to set the axis No. of drive unit.

Rotary axis setting switch (SW1)

USB communication connector (CN5)

Connect with the personal computer.

Battery holder

Contains the battery for absolute position data backup.

Encoder connector (CN2)

Used to connect the servo motor encoder.

SSCNET cable connector (CN1B)

Used to connect the rear axis drive unit. For the final axis,

puts a cap.

I/O signal connector (CN3)

Used to connect digital I/O signals.

More over an analog monitor is output

SSCNET cable connector (CN1A)

Used to connect the servo system controller or the front

axis drive unit.

Converter unit connectors (CN40A)

Connect to CN40 of the converter unit.

Battery connector (CN4)

Used to connect the battery for absolute position data

Converter unit connectors (CN40B)

Connect the termination connector (MR-J3-TM).

Fixed part

(4 places)

Name/Application

Detailed

explanation

Protective earth (PE) terminal ( )

Ground terminal.