Configuration and Use Manual 97

Troubleshooting

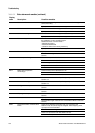

Troubleshooting DisplayDiagramsOperation

Inaccurate flow rate Bad flow cal factor Verify characterization. See Section 6.7.4.

Inappropriate measurement unit Check measurement units using a

PROFIBUS host or configuration tool.

Bad sensor zero Rezero the flowmeter. See Section 3.6.

Bad density calibration factors Verify characterization. See Section 6.7.4.

Bad flowmeter grounding See Section 6.9.3.

Slug flow See Section 6.10.

Wiring problem Verify all sensor-to-transmitter wiring and

ensure the wires are making good

contact. Refer to the installation manual.

Inaccurate density reading Problem with process fluid Use standard procedures to check quality

of process fluid.

Bad density calibration factors Verify characterization. See Section 6.7.4.

Wiring problem Verify all sensor-to-transmitter wiring and

ensure the wires are making good

contact. Refer to the installation manual.

Bad flowmeter grounding See Section 6.9.3.

Slug flow See Section 6.10.

Sensor cross-talk Check environment for sensor with similar

(±0.5 Hz) tube frequency.

Plugged flow tube Check drive gain and tube frequency.

Purge the flow tubes. Sensor may need to

be replaced.

Temperature reading significantly

different from process temperature

RTD failure Check for alarm conditions and follow

troubleshooting procedure for indicated

alarm.

Incorrect calibration factors Perform temperature calibration. See

Section 3.8.

Verify characterization. See Section 3.3.

Temperature reading slightly different

from process temperature

Incorrect calibration factors Perform temperature calibration. See

Section 3.8.

Verify characterization. See Section 3.3.

Unusually high density reading Plugged flow tube Check drive gain and tube frequency.

Purge the flow tubes.

Incorrect K2 value Verify characterization. See Section 6.7.4.

Unusually low density reading Slug flow See Section 6.10.

Incorrect K2 value Verify characterization. See Section 6.7.4.

Unusually high tube frequency Sensor erosion Contact Micro Motion Customer Service.

Unusually low tube frequency Plugged flow tube Check drive gain and tube frequency.

Purge the flow tubes. Sensor may need to

be replaced.

Unusually low pickoff voltages Several possible causes See Section 6.12.5.

Unusually high drive gain Several possible causes See Section 6.12.3.

Table 6-3 Output problems and possible remedies (continued)

Symptom Cause Possible remedies