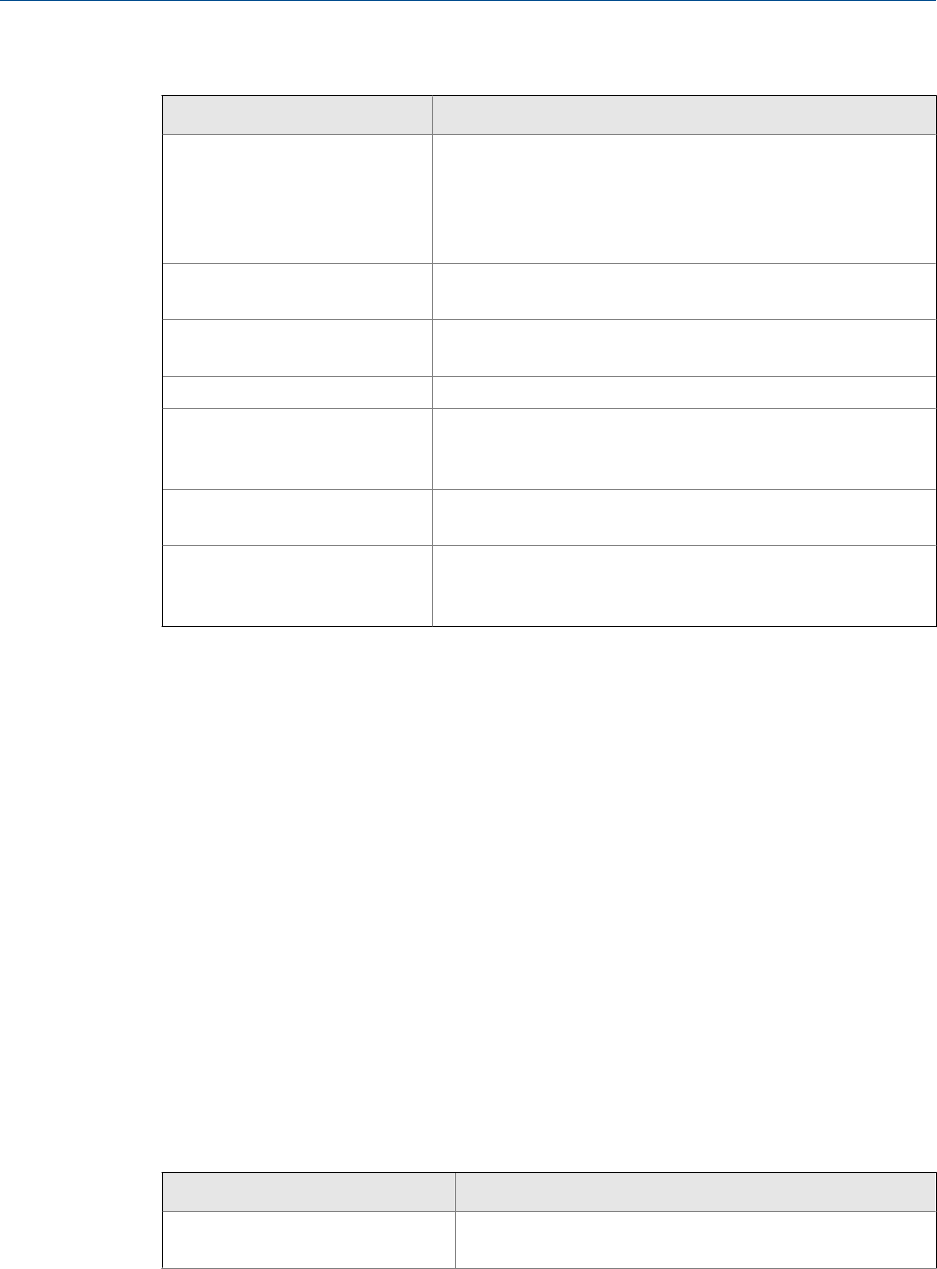

Possible causes and recommended actions for low pickoff voltageTable 10-10:

Possible cause Recommended actions

Air entrainment • Increase the inlet or back pressure at the sensor.

• If a pump is located upstream from the sensor, increase the

distance between the pump and sensor.

• The sensor may need to be reoriented. Consult the installa-

tion manual for your sensor for recommended orientations.

Faulty wiring runs between the

sensor and transmitter

Verify wiring between sensor and transmitter.

Process flow rate beyond the lim-

its of the sensor

Verify that the process flow rate is not out of range of the sen-

sor.

Slug flow Check for slug flow. See Section 10.25.

No tube vibration in sensor • Check for plugging.

• Ensure sensor is free to vibrate (no mechanical binding).

• Verify wiring.

Moisture in the sensor electron-

ics

Eliminate the moisture in the sensor electronics.

The sensor is damaged, or sensor

magnets may have become de-

magnetized

Replace the sensor.

10.27.1 Collect pickoff voltage data

Pickoff voltage data can be used to diagnose a variety of process and equipment

conditions. Collect pickoff voltage data from a period of normal operation, and use this

data as a baseline for troubleshooting.

Procedure

1.

Navigate to the pickoff voltage data.

2. Observe and record data for both the left pickoff and the right pickoff, over an

appropriate period of time, under a variety of process conditions.

10.28 Check for electrical shorts

Shorts between sensor terminals or between the sensor terminals and the sensor case can

cause the sensor to stop working.

Possible causes and recommended actions for electrical shortsTable 10-11:

Possible cause Recommended action

Moisture inside the junction box Ensure that the junction box is dry and no corrosion is

present.

Troubleshooting

Configuration and Use Manual 175