72 Micro Motion

®

Model 2200S Transmitters

Testing and Moving to Production

If desired, you can use one of these functions to return the meter to operation while you are

troubleshooting the cause of the zero failure (see Section 10.6). Availability of these functions

depends on the tool you are using to zero the flowmeter:

• If you are using the Communicator or the display, only Restore Factory Zero is available.

• If you are using ProLink II, both Restore Prior Zero and Restore Factory Zero are available.

7.2.1 Preparing for zero

To prepare for the zero procedure:

1. Apply power to the flowmeter. Allow the flowmeter to warm up for approximately 20 minutes.

2. Run the process fluid through the sensor until the sensor temperature reaches the normal

process operating temperature.

3. Close the shutoff valve downstream from the sensor.

4. Ensure that the sensor is completely filled with fluid.

5. Ensure that the process flow has completely stopped.

CAUTION! Ensure that there is no fluid

flowing through the sensor while zero calibration is in process. If there is, the calibration results

may be inaccurate, resulting in inaccurate process measurement.

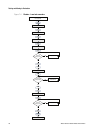

7.2.2 Performing the zero procedure

To zero the flowmeter:

• Using the display, see Figure 7-1.

• Using the Communicator, see Figure 7-2.

• Using ProLink II, see Figure 7-3.