32 Micro Motion

®

Model 2200S Transmitters

Configuring Process Measurement

Configuration

To characterize the flowmeter using the Communicator:

1. Select

Detailed Setup > Charize Sensor.

2. In the Sensor Selection menu, select

Other.

3. In the Flow menu, set the

FlowCal parameter.

4. In the Density menu, set the remainder of the parameters listed in Table 4-1.

To characterize the flowmeter using ProLink II:

1. Click

ProLink > Configuration.

2. On the Device panel, set Sensor Type to Curved.

3. On the Flow panel, set the

Flow Cal parameter.

4. On the Density panel, set the remainder of the parameters listed in Table 4-1.

4.3 Configuring general flow parameters

The general flow parameters include:

• Flow Direction

• Flow Damping

4.3.1 Flow direction

The Flow Direction parameter controls how the transmitter reports flow rate and how flow is added to

or subtracted from the totalizers, under conditions of forward flow, reverse flow, or zero flow.

• Forward (positive) flow moves in the direction of the arrow on the sensor.

• Reverse (negative) flow moves in the direction opposite of the arrow on the sensor.

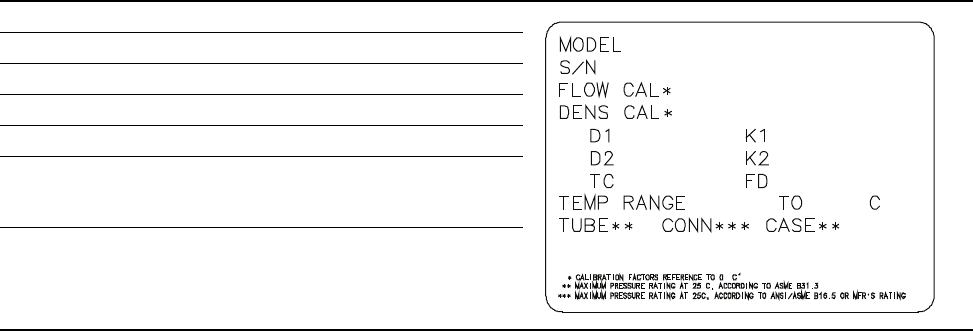

Table 4-1 Characterization parameters

Parameter Description Sample sensor tag

K1 Tube period when sensor is filled with air

K2 Tube period when sensor is filled with water

FD Density correction factor for high flow rates

D1 Density of air for K1

D2 Density of water for K2

TC Temperature coefficient to compensate for the

effect of temperature on the density

measurement

Flowcal Flow calibration factor to define the

relationship between sensor data and mass

flow rate and compensate for the effect of

temperature on the mass measurement

19.0005.13

0.0010

0.9980

12502.000

14282.000

4.44000

310

12500142864.44