112 Micro Motion

®

Model 2200S Transmitters

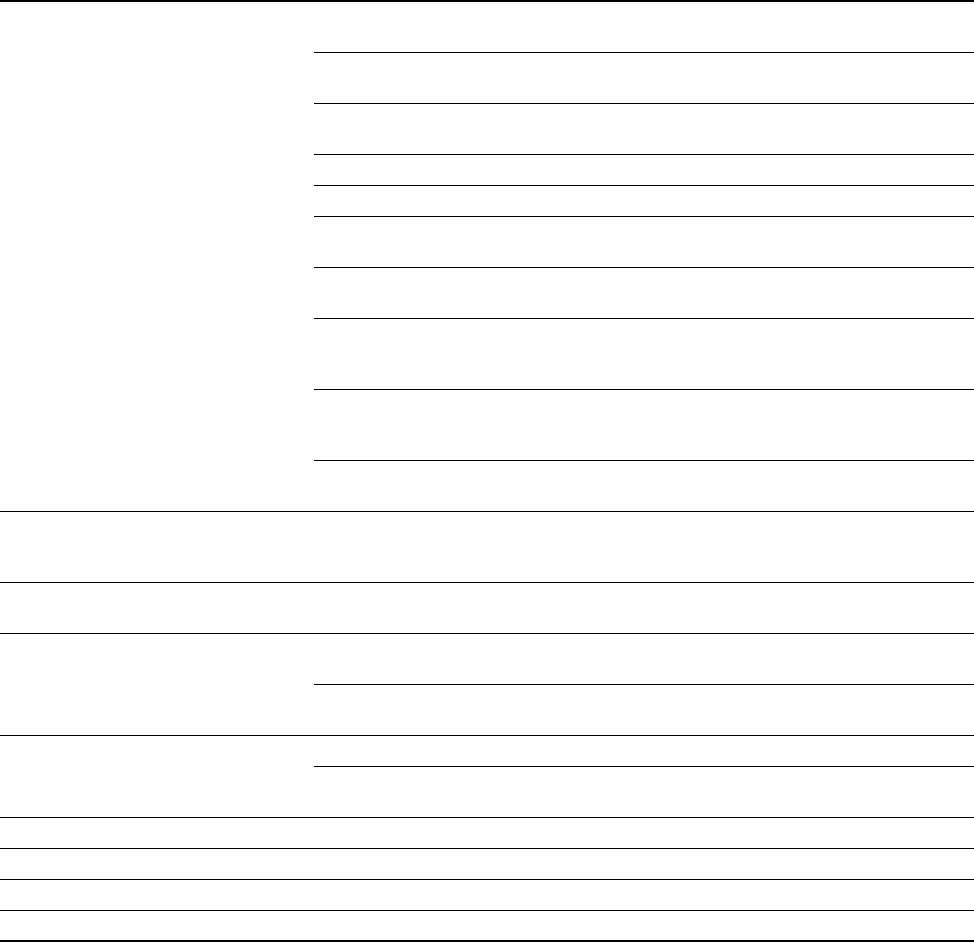

Troubleshooting

Inaccurate density reading Problem with process fluid • Use standard procedures to check

quality of process fluid.

Bad density calibration factors • Verify characterization. See

Section 4.2.

Wiring problem • Check the sensor circuitry. See

Section 10.24.

Bad flowmeter grounding • See Section 10.14.2.

Slug flow • See Section 10.17.

Sensor cross-talk • Check environment for sensor with

similar (±0.5 Hz) tube frequency.

Plugged flow tube • Check drive gain and tube frequency.

Purge the flow tubes.

Incorrect sensor orientation • Sensor orientation must be

appropriate to process fluid. See the

installation manual for your sensor.

RTD failure • Check for alarm conditions and follow

troubleshooting procedure for

indicated alarm.

Physical characteristics of sensor have

changed

• Check for corrosion, erosion, or tube

damage.

Temperature reading significantly

different from process temperature

RTD failure • Check for alarm conditions and follow

troubleshooting procedure for

indicated alarm.

Temperature reading slightly different

from process temperature

Sensor leaking heat • Insulate the sensor.

Unusually high density reading Plugged flow tube • Check drive gain and tube frequency.

Purge the flow tubes.

Incorrect K2 value • Verify characterization. See

Section 4.2.

Unusually low density reading Slug flow • See Section 10.17.

Incorrect K2 value • Verify characterization. See

Section 4.2.

Unusually high tube frequency Sensor erosion • Contact Micro Motion.

Unusually low tube frequency Plugged flow tube, corrosion, or erosion • Purge the flow tubes.

Unusually low pickoff voltages Several possible causes • See Section 10.23.3

.

Unusually high drive gain Several possible causes • See Section 10.23.2.

Table 10-4 Process variables problems and remedies continued

Symptom Cause Suggested remedy