14 The Tool Compensation

80

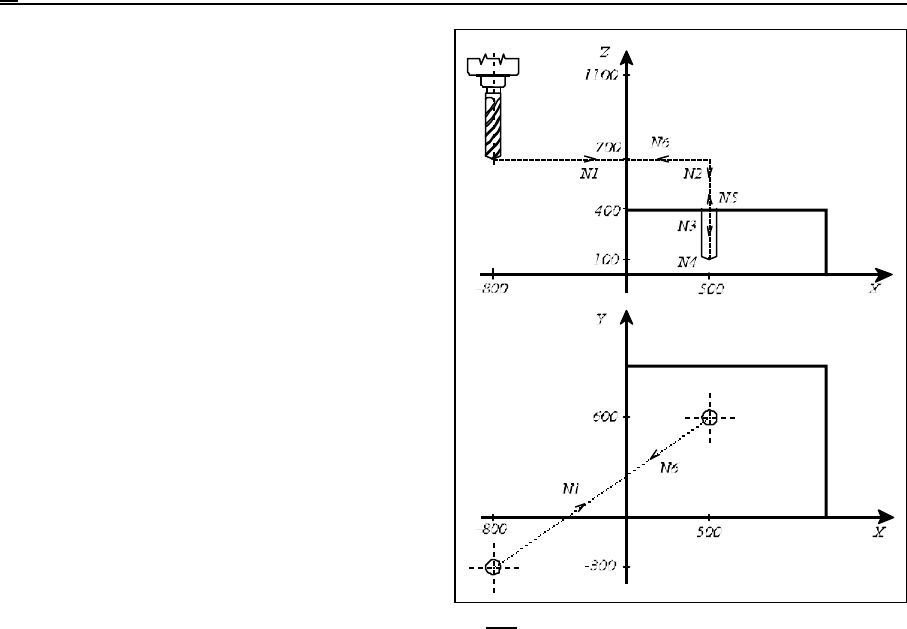

Fig. 14.3-1

If, however, instruction G49 is used, any

reference to address H will be ineffective until

G43 or G44 is programmed.

At power-on, the value defined in parameter

group CODES decides which code is effective

(G43, G44, G49).

The example below presents a simple drilling

operation with tool length compensation taken

into account:

length of drilling tool, H1=400

N1 G90 G0 X500 Y600 (positioning in plane X, Y)

N2 G43 Z410 H1 (moving to Z410 with H1 length compensation)

N3 G1 Z100 F180 (drilling as far as Z100 with F180 feed)

N4 G4 P2 (dwell for 2 seconds)

N5 G0 Z1100 H0 (removing the tool and canceling the length

compensation; the tool's tip is in the X700 point)

N6 X-800 Y-300 (returning with rapid traverse in plane X, Y)

14.4 Tool Offset (G45...G48)

G45 increases the movement amount with the offset value

G46 decreases the movement amount with the offset value

G47 increases the movement amount by twice with the offset value

G48 decreases the movement amount by twice with the offset value

Any one of commands G45...G48 will be effective with the compensation selected with the D code

until another value is called in conjunction with a command G45...G48.

Being non-modal codes, they are effective only in the block in which they have been specified.

In the case of an absolute data specification, the amount of movement will be the difference between

the end point defined in the current block and the end point of the previous block. Any increase or

decrease refers to the direction of motion produced in this way.