20 Custom Macro

198

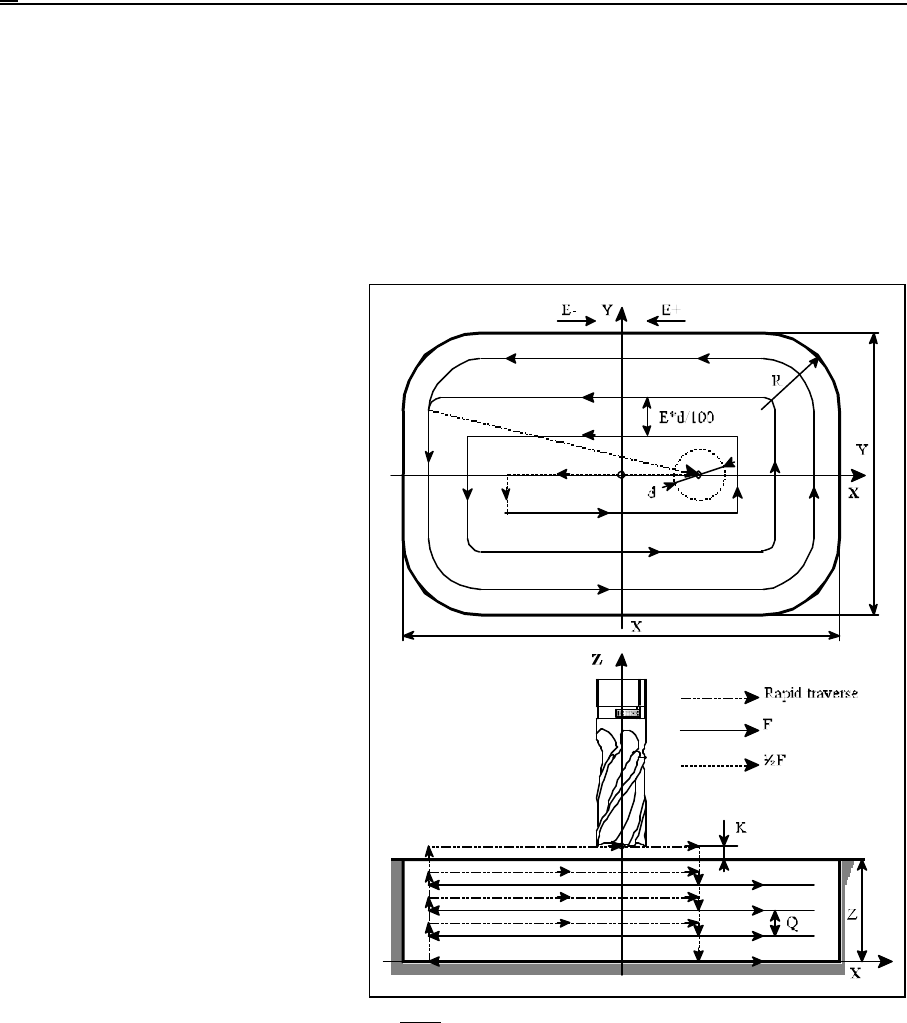

Fig. 20.18-1

20.18 Pocket-milling Macro Cycle

Instruction

G65 P9999 X Y Z I J K R F D E Q M S T

will start a pocket-milling cycle. For the execution of the cycle, macro of program number O9999 has

to be filled in the memory, from the PROM memory of the control.

Prior to calling the cycle, the tool must be brought over the geometric center of the pocket in the

selected plane, at a safety distance over the workpiece. At the end of the cycle the tool will be retracted

to the same point.

The addresses in the block have the

following meaning:

X = size of pocket in direction X

Y = size of pocket in direction Y

Z = size of pocket in direction Z

Instructions G17, G18, G19 will define

the length, width and depth of the

pocket for the three coordinates. For

example, in case of G17 Z will be the

depth of the pocket, the longer one of

X and Y will be the length of pocket

(the shorter one will be the width

thereof). Those values have to be

entered in absolute values as positive

numbers.

R = the radius of the corners of the

pocket.

Rounding (if any) of the corners of the

pocket should be specified at address

R. Unless address R is filled, the

rounding of the pocket's corners will be

rounded with the tool radius.

I = safety distance toward the depth

of pocket in the case of G19

J = safety distance toward the depth

of pocket in the case of G18

K = safety distance toward the depth of pocket in the case of G17

Depending on the plane selected, the safety allowance in the direction of the tool has to be specified at

the addresses I(G19), J(G18) or K(G17) in the block. When the cycle is started, the control assumes

that the tip of the tool is located at that distance from the surface of the workpiece. While the pocket

is being milled, as soon as the material of a level is removed, the tool will be lifted to that distance so that

it can be brought to the start point for milling the next level.

D = address of register containing the radius compensation of the tool

The radius-compensation number of the tool, used in the program is to be specified mandatorily at

address D. Besides, the milling of a pocket has to be carried out in state G40.