10 The Spindle Function

63

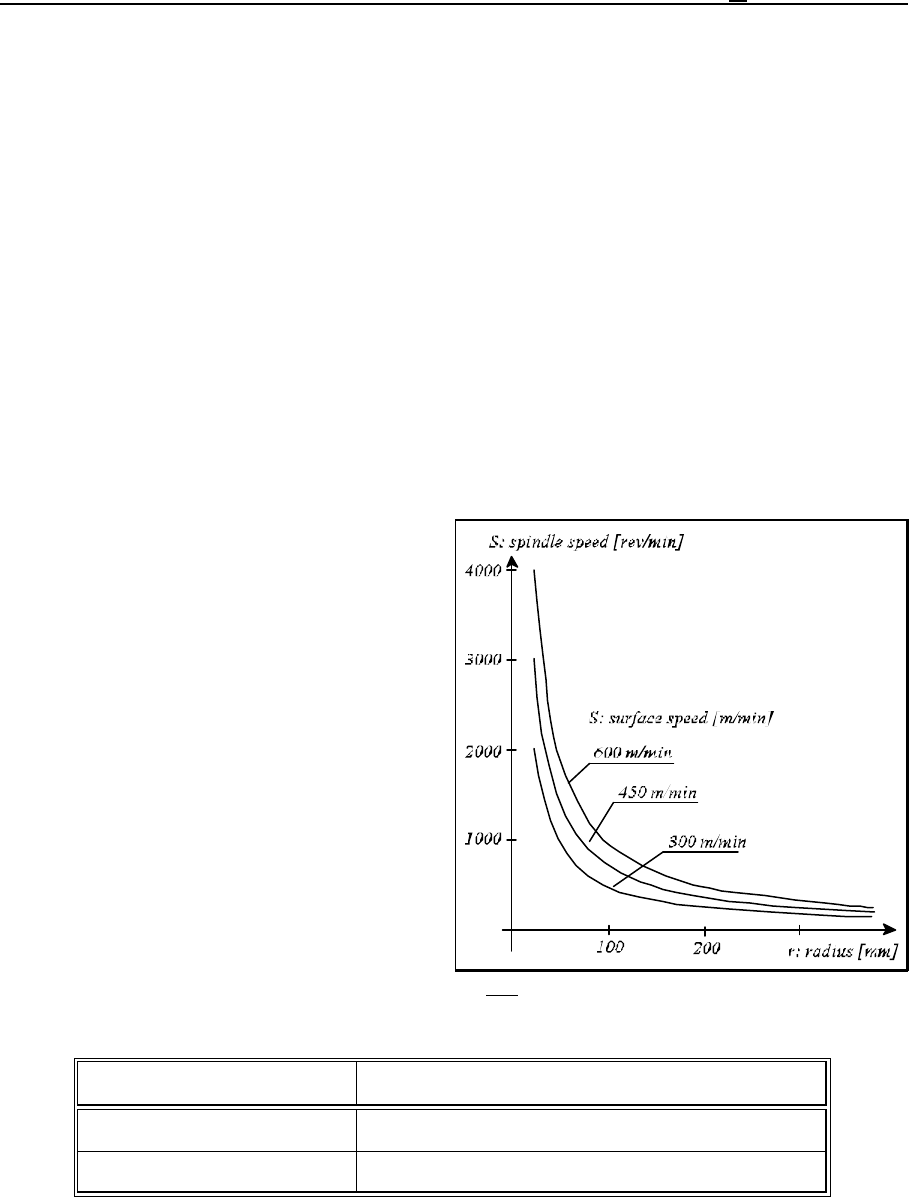

Fig. 10.2-1

10 The Spindle Function

10.1 Spindle Speed Command (code S)

With a number of max. five digits written at address S, the NC will give a code to the PLC.

Depending on the design of the given machine-tool, the PLC may interpret address S as a code or

as a data of revs/minute.

When a movement command and a spindle speed (S) are programmed in a given block, function S

will be issued during or after the motion command. The machine tool builder will define the way of

execution.

The speeds specified at address S are modal values. At the time of power-on, the control will

assume value S0. The spindle speed has a minimum and a maximum limit in each gear ratio range.

They are defined by the machine-tool builder in parameters and the control does not let the speed

outside of this range.

10.2 Programming of Constant Surface Speed Control

Constant surface speed control function can

only be used in case of infinitely variable speed

main drive. In this case the control can change

the spindle speed so that the tool speed is

constant relative to the surface of the

workpiece and is equal to the programmed

value.

The constant surface speed must be specified

in function of the input unit on the basis of the

table below:

Input unit Unit of constant surface speed

mm (G21 metric) m/min

inch (G20 inch) feet/min