14 The Tool Compensation

104

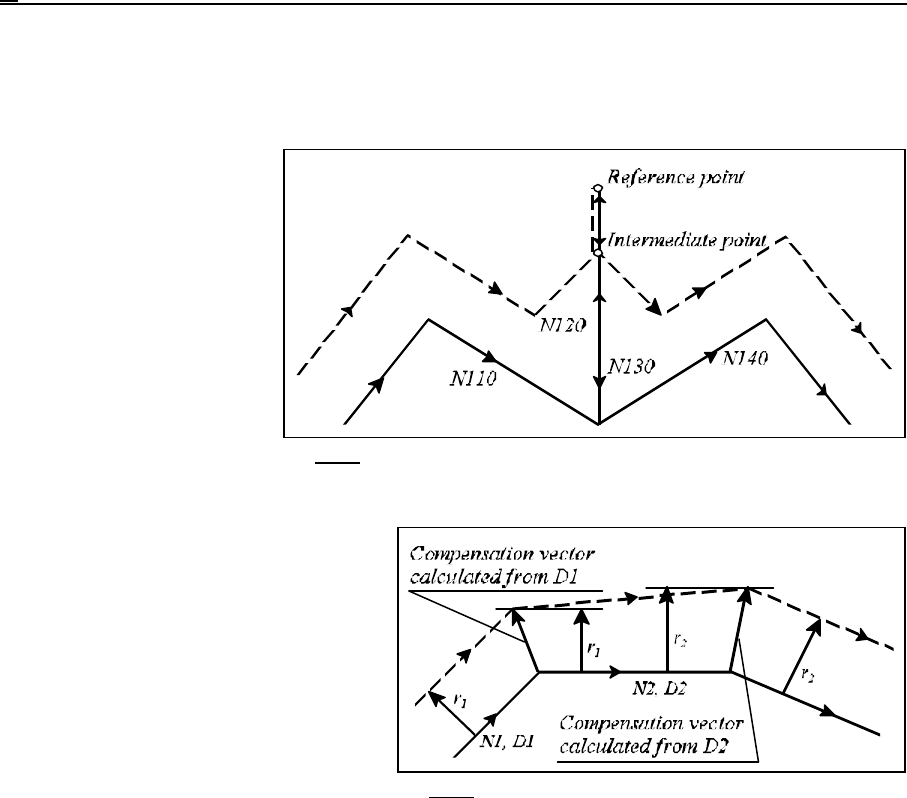

Fig. 14.5.7-8

Fig. 14.5.7-9

If G28 or G30 is programmed (followed by G29) between two blocks in offset mode, the

compensation vector will be deleted at the end point of the block it positions the tool to the

intermediate point, the tool will move to the reference point, and the vector will be restored at the

end point of the returning block G29.

For example:

...G91 G17

G41...

N110 G1 X80 Y–50

N120 G28 Y80

N130 G29 Y0

N140 X80 Y50

...

A new compensation value can also be

called at address D in offset mode. In the

event of a reversal in the sign of the

radius, the direction of motion along the

contours will be reversed (see earlier).

Otherwise, the following procedure will

be applicable. The compensation vector

will be calculated with the new radius

value at the end point of the interpolation,

in which the new address D has been

programmed. Since the compensation vector has been computed with the previous radius value at

the start point of that block, the path of the tool center will not be parallel to the programmed path.

A new radius compensation value can be called at address D in a circular interpolation, too, this

time, however, the tool center will be moving along an arc with a variable radius.

A special instance of the foregoing is canceling or setting up the compensation with D00 or Dnn,

respectively, while in offset mode. Notice the difference in tool paths with reference to the following

example, when the compensation is set up with G41 or G42 and canceled with G40, or when the

compensation is set up and canceled by programming D.