9 Coordinate Systems, Plane Selection

58

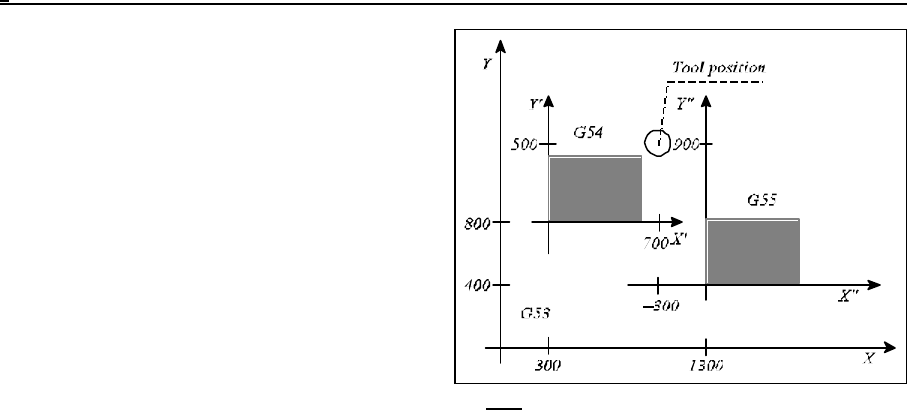

Fig. 9.2.2-2

After a change of the work coordinate system,

the tool position will be displayed in the new

coordinate system. For instance, there are two

workpieces on the table. The first work

coordinate system (G54) has been assigned to

zero point of one of the workpieces, which has

an offset of X=300, Y=800 (calculated in the

machine coordinate system). The second work

coordinate system (G55) has been assigned to

the zero point of the other workpiece, which has

an offset of X=1300, Y=400 (calculated in the

machine coordinate system). The tool position is

X'=700, Y'=500 in X', Y's’ coordinate system

(G54). As a result of instruction G55, the tool position will be interpreted in the X", Y" coordinate

system (X"=-300, Y"=900).

9.2.3 Programmed Setting of the Work Zero Point Offset

It is also programable to set the work coordinate system and the common offset thereof with

program instructions.

This is accomplished with instruction

G10 v L2 Pp

where

p = 0 sets the common offset,

p = 1...6 selecting work coordinate system 1.- 6.

v = offset for each axis.

The coordinate data are entered invariably as rectangular (Cartesian) absolute values. G10 is a one-

shot (non-modal) instruction.

9.2.4 Creating a New Work Coordinate System (G92)

Instruction

G92 v

will establish a new work coordinate system in such a way that coordinate point v of the new system

will be a selected point - e.g. the tool's tip (if a length compensation is programmed) or the base

point of the tool holder (in lack of a length compensation). Afterwards any additional absolute

command will refer to that new work coordinate system, and the positions will also be displayed in

that coordinate system. The coordinates specified in command G92 will always be interpreted as

rectangular absolute values.