9 Coordinate Systems, Plane Selection

55

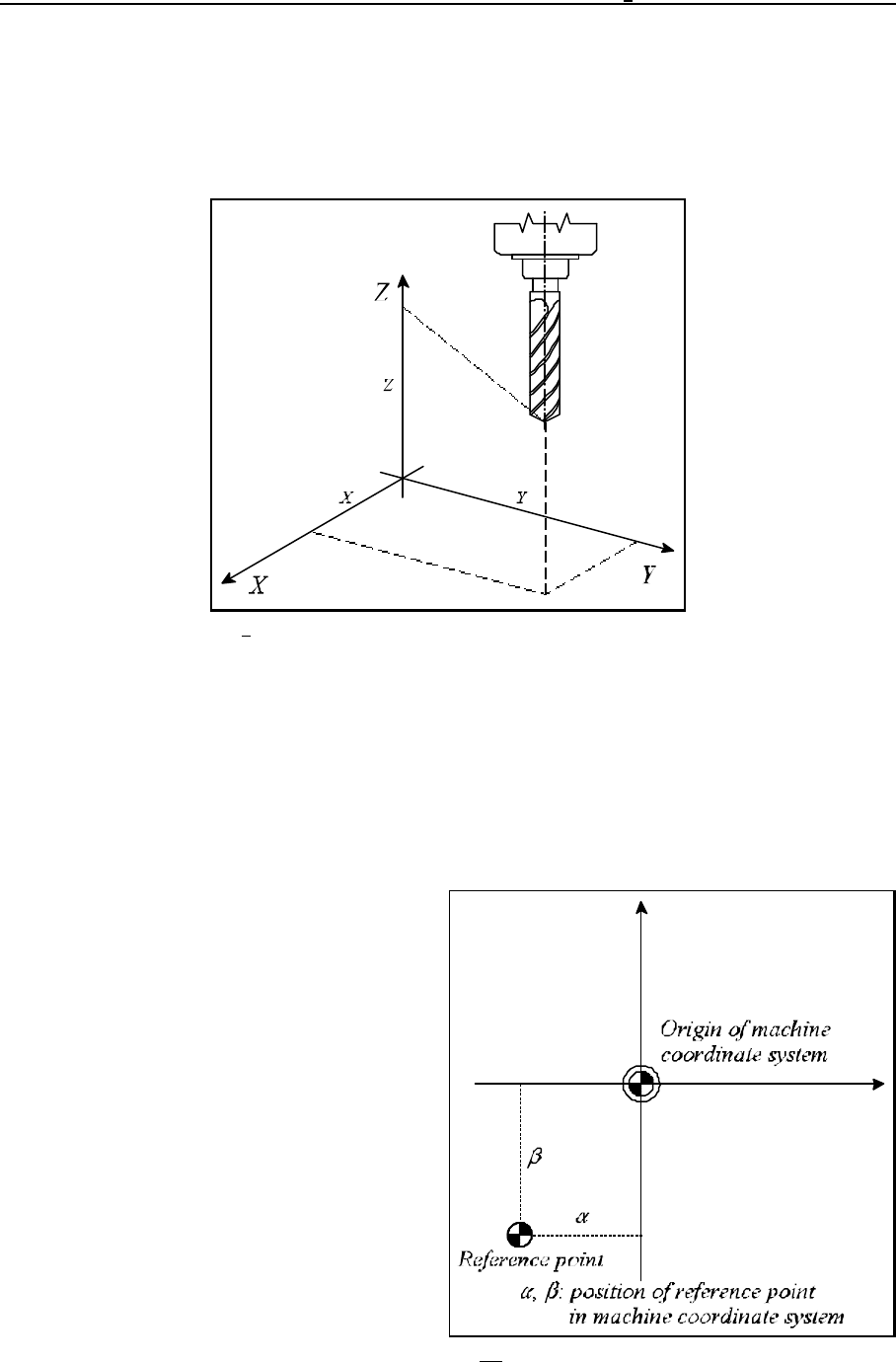

Fig. 9-1

Fig. 9.1-1

9 Coordinate Systems, Plane Selection

The position, to which the tool is to be moved, is specified with coordinate data in the program.

When 3 axes are available (X, Y, Z), the position of the tool is expressed by three coordinate data

X____ Y____ Z____ :

The tool position is expressed by as many different coordinate data as is the number of axes on the

machine. The coordinate data refer invariably to a given coordinate system.

The control will differentiate three different coordinate systems.

1. the machine coordinate system,

2. the workpiece's coordinate system,

3. the local coordinate system.

9.1 The Machine Coordinate System

The machine zero point, i.e., the origin of the

machine coordinate system, is a point on the

given machine-tool, that is usually defined by the

machine tool builder. The control will define the

machine coordinate system at the time of

returning to the reference point.

Once the machine coordinate system has been

defined, it will not be altered by the change of

the work coordinate system (G54 ... G59) or

by other coordinate transformation (G52, G92),

only by a power-off of the control system.