6 The Feed

44

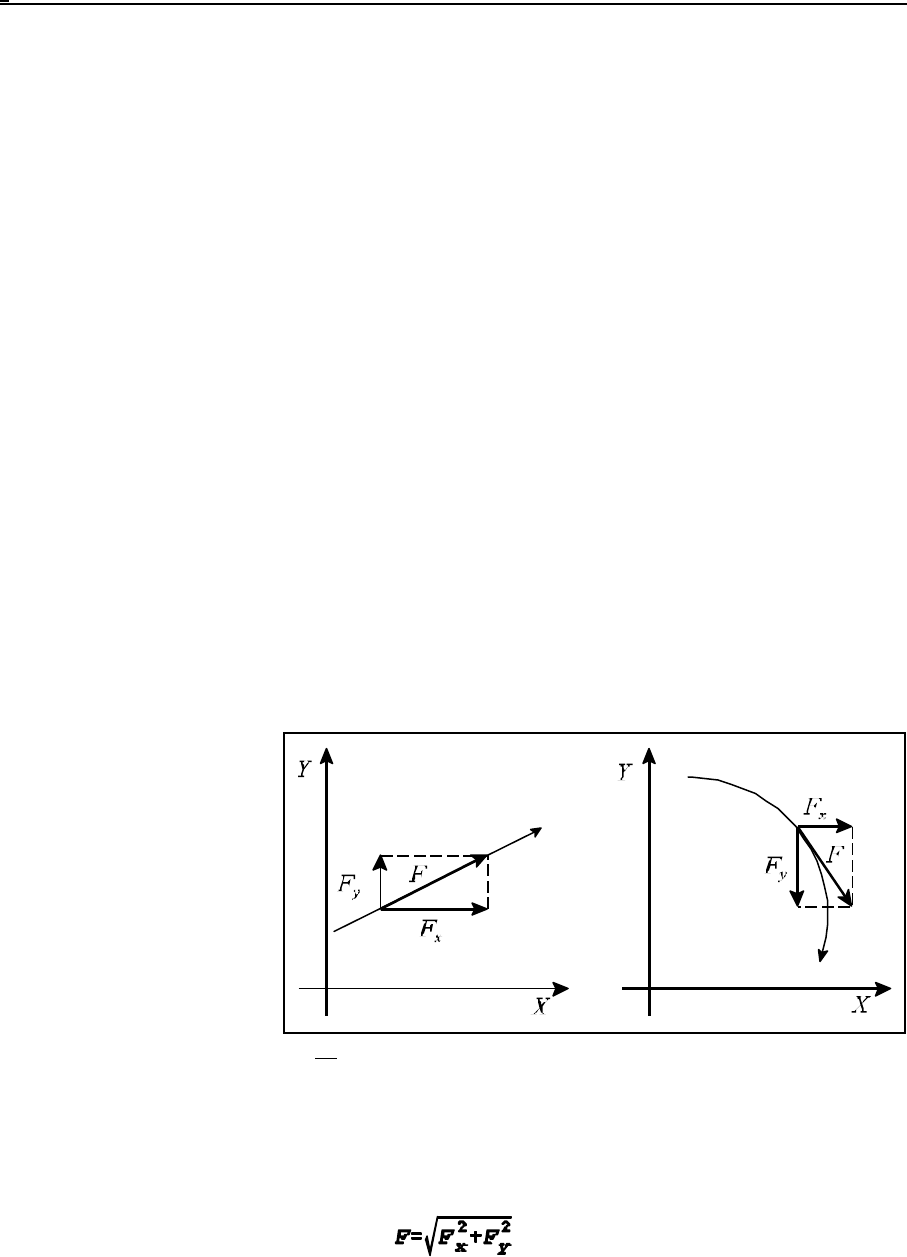

Fig. 6.2-1

6 The Feed

6.1 Feed in rapid travers

G00 commands a positioning in rapid traverse.

The value of rapid traverse for each axis is set by parameter by the builder of the machine. The rapid

traverse may be different for each axis.

When several axes are performing rapid traverse motions simultaneously, the resultant feed will be

calculated in such a way that the speed component of each axis will not exceed the particular rapid

traverse value (set as a parameter), and the positioning is accomplished in a minimum of time.

Rapid traverse rate is modified by the rapid traverse override switch that can be

F0: defined by parameter RAPOVER in %,

and 25%, 50%, 100%.

The rapid traverse rate will not exceed 100%.

Rapid traverse will be stopped if the state of the feedrate override switch is 0%.

In lack of a valid reference point, the reduced rapid traverses defined by the machine tool builder by

parameter will be effective for each axis until the reference point is returned.

Rapid traverse override values can be connected to the feedrate override switch.

When the slide is being moved by the jog keys, the speed of rapid traverse is different from the

rapid traverse in G00, it is also selected by parameters separately for each axis. Appropriately it is

lower than the speed of positioning for human response times.

6.2 Cutting Feed Rate

The feed is programmed at

address F.

The programmed feed is

accomplished in blocks of

linear (G01) and circular

interpolations (G02, G03).

The feed is accomplished

tangentially along the prog-

rammed path.

F - tangential feed (programmed value)

F

x

- feed component in the X direction

F

y

- feed component in the Y direction

Except for override and stop inhibit states (G63), the programmed feed can be modified over the

range of 0 to 120% with the feed-override switch.