1 Introduction

15

Fig. 1.2-8

the code of G90 (absolute data specification) and the value of F (Feed), specified in block N15, will

be modal in blocks N16 and N17. Thus it is not necessary to specify those functions in each block

followed.

One-shot (Non-modal) Functions

Some codes or values are effective only in the block in which they are specified. These are one-shot

functions.

Spindle Speed Command

The spindle speed can be specified at address S. It is also termed as "S function". Instruction S1500

tells the spindle to rotate at a speed of 1500 rpm

Tool Function

In the course of machining different tools have to be employed for the various cutting operations.

The tools are differentiated by numbers. Reference can be made to the tools with code T.

Instruction T25 in the program means that tool No. 25 has to be changed. The tool change can be

carried out manually or automatically, depending on the design of the machine.

Miscellaneous Functions

A number of switching operations have to be carried out in the course of machining. For example,

starting the spindle, turning on the coolant. Those operations can be performed with M

(miscellaneous) functions. E.g., in the series of instructions

M3 M8

M3 means “rotate the spindle clockwise”, M8 means "turn on the coolant".

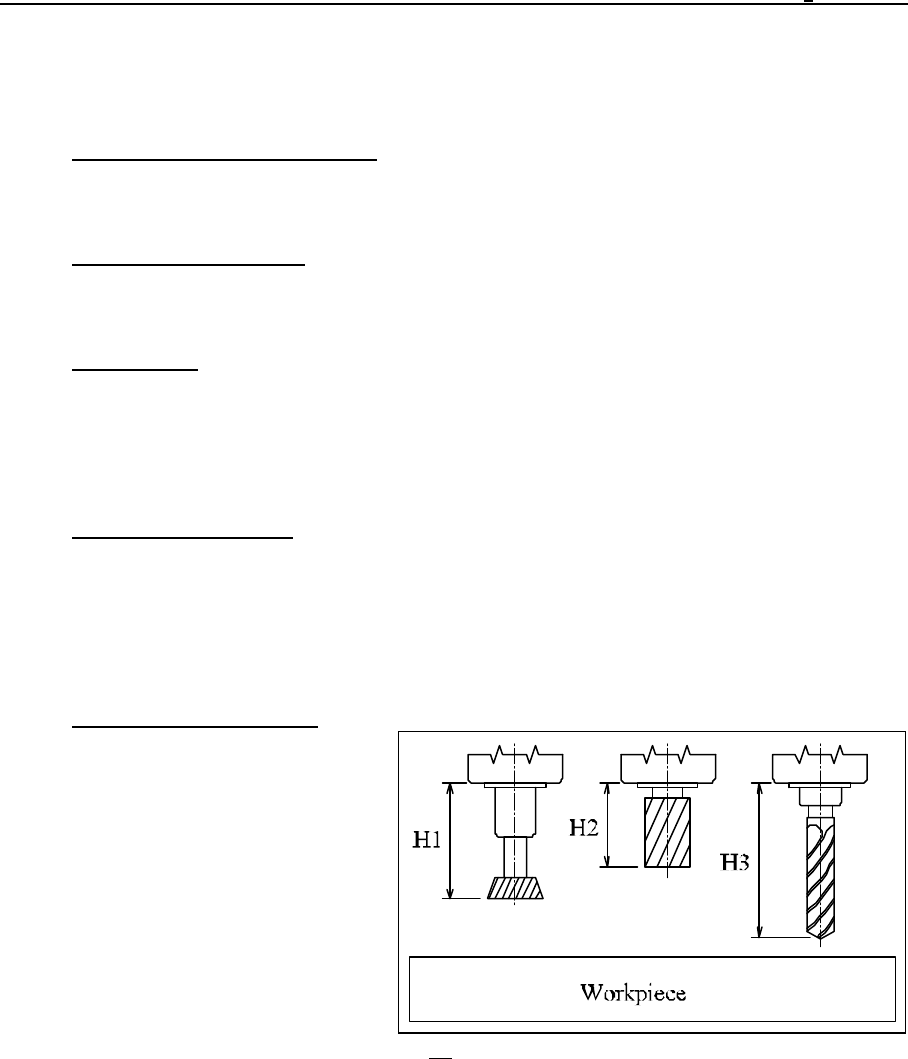

Tool Length Compensation

In the course of machining, tools of

different length are employed for the

various operations. On the other hand, a

given operation also has to be performed

with tools of different lengths in series

production (e.g., when the tool breaks).

In order to make the motions described in

the part program independent of the

length of the tool, the various tool lengths

must be set in control system. If the

program is intended to move the tip of the

tool to the specified point, the value of the

particular length data has to be called. This is feasible at address H. E.g., instruction H1 refers to

length data No.1. Henceforth the control will move the tip of the tool to the specified point. That

procedure is referred to as setting “tool length compensation" mode.