10 The Spindle Function

66

10.5 Spindle Positioning (Indexing)

A spindle positioning is only feasible after the spindle position control loop has been closed after

orientation. Accordingly, this function is used for closing the loop. The loop will be opened by

rotation command M3 or M4.

If the value of parameter INDEX1=1 (indicating that the main drive position control loop can be

closed) and the value of parameter INDEX_C1=0, the spindle indexing will be performed by

function M.

Under such conditions function M from the threshold value set on parameter M_NUMB1 to

M_NUMB1+360 will be interpreted as a spindle indexing commands, i.e., the threshold number will

be subtracted from the programmed value of M, and the number obtained will be treated as an

incremental displacement specified in degrees.

Thus, if M_NUMB1=100, command M160 means that the spindle must be turned by 160-100=60

degrees from its current position. The direction of rotation is selected by parameter CDIRS1, its rate

is selected by parameter RAPIDS1.

10.6 Spindle Speed Fluctuation Detection (G25, G26)

Command

G26

enables spindle speed fluctuation detection, while command

G25

cancels it. After power-on or RESET the control is set to state G26, i.e., spindle speed fluctuation

detection is on. This function signals abnormalities occurring in the course of spindle rotation, as the

result of which, e.g., spindle seizure can be avoided.

The speed fluctuation detection is influenced by 4 parameters. These parameters can be overwritten

from a program with addresses following command G26. The overwritten parameters are kept upon

power-off. The parameters are overwritten as the effect of command

G26 Pp Qq Rr Dd.

The below table contains the parameter interpretations:

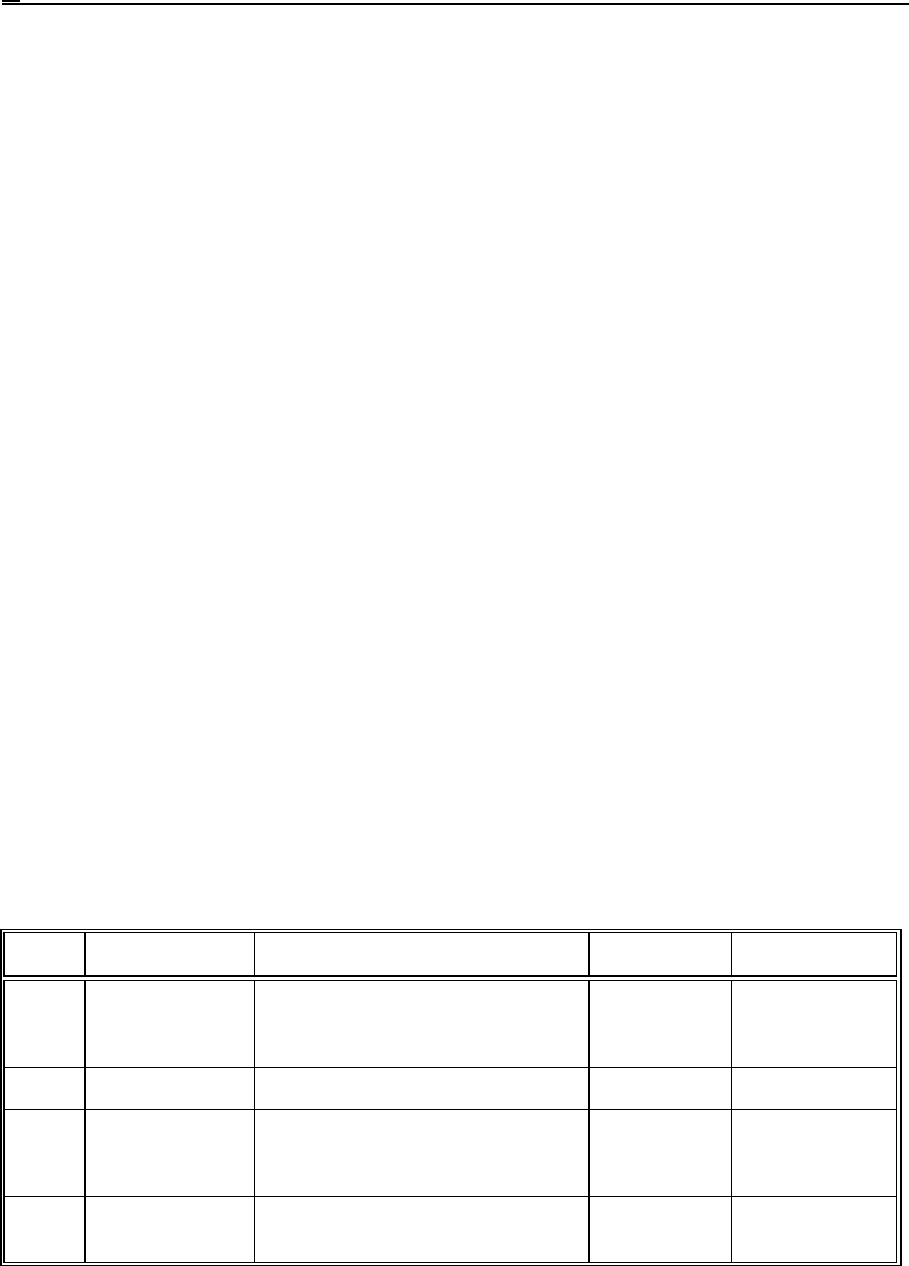

name parameter meaning unit value limit

p 5001 TIME time from the issue of a new spindle

speed command to the start of

checking

100 msec 65535

q 5002 SCERR tolerance of a specified spindle speed % 1-50

r 5003 FLUCT% allowable amount of spindle speed

fluctuation in the percentage of

programmed speed

% 1-50

d 5004 FLUCTW spindle speed fluctuation in absolute

value

revs/min 65535

The process of speed fluctuation detection is as follows.