10 The Spindle Function

68

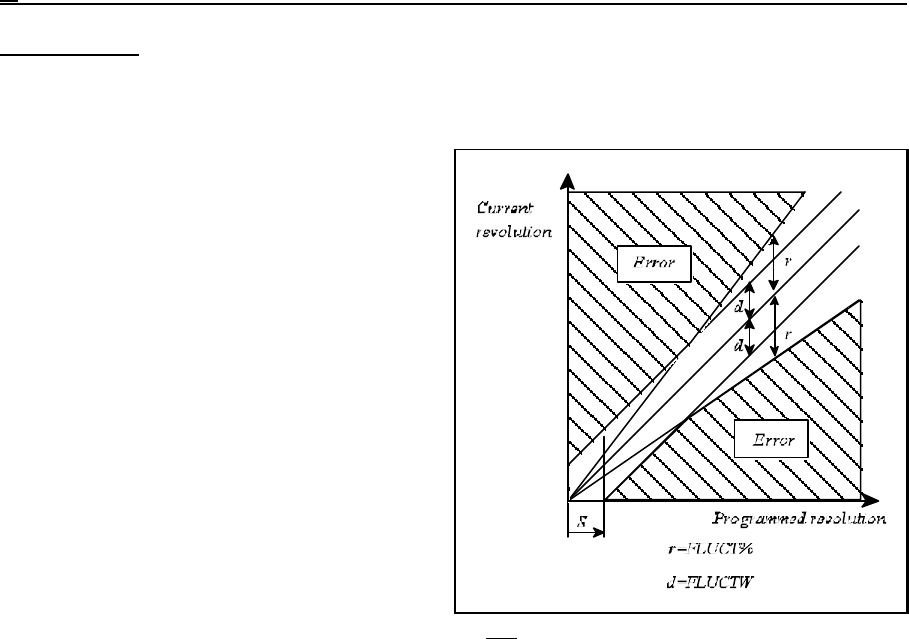

Fig. 10.6-3

Detecting Error

In the course of detection the control sends error message in case the deviation between current and

specified spindle speed exceeds

- the tolerance limit specified by value "r" in

percent of the command value and

- also the absolute tolerance limit specified by

value "d"

When the current speed has exceeded both

tolerance limits, the NC sets flag I656 to PLC.

The speed range, in which the NC issues

alarm, can be seen on the 3rd figure. If the

specified spindle speed is under value "S"

apparent in the figure, the NC issues alarm,

provided the current speed is 0 revs/min for

more than 1 second.

– The spindle speed fluctuation detection is

effective only if the spindle is mounted

with encoder.

– The specified spindle speed, according to

which the current spindle speed is

detected is calculated by taking the

override, the revolution range limits and the programmed maximum revolution (G92 S_) in

constant surface speed calculation (G96) into account.

– The spindle speed fluctuation detection is effective only in case of G26 and rotating spindle (state

M3 or M4).

– Command G26 must be programmed in single block.