14 The Tool Compensation

107

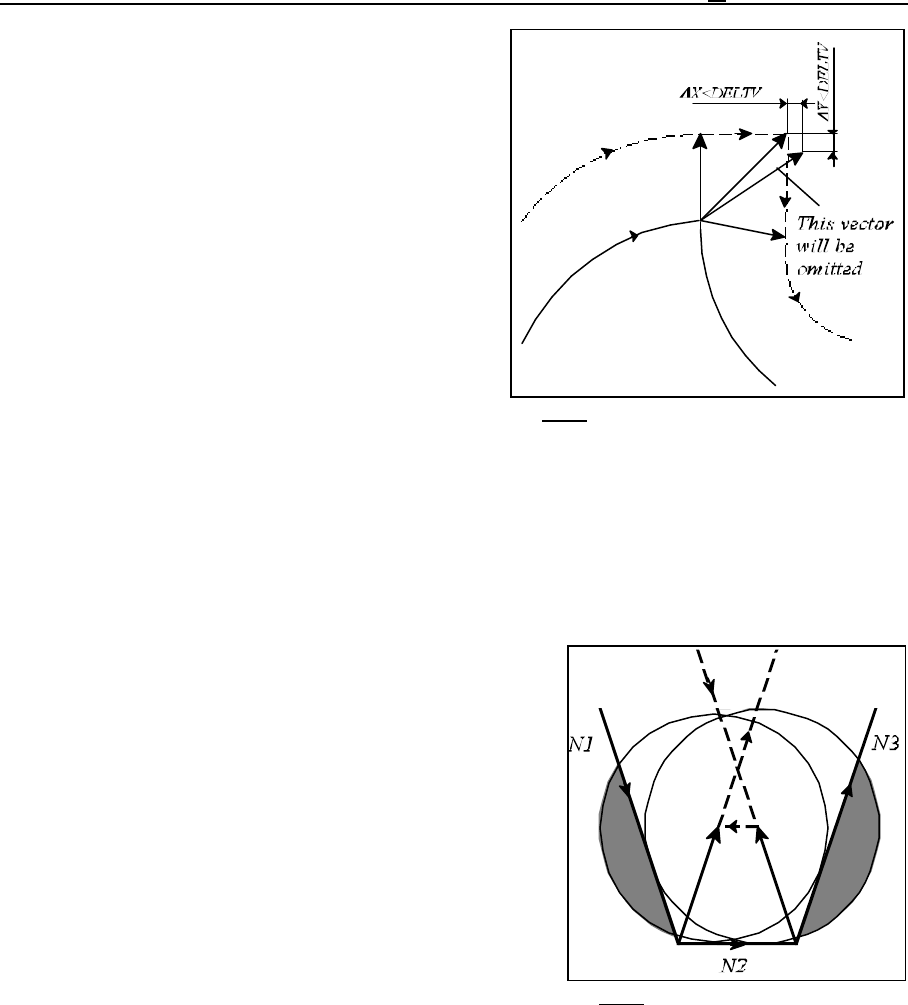

Fig. 14.5.7-15

Fig. 14.5.8-1

Two or more compensation vectors may be produced

when going around sharp corners. When their end

points lie close to each other, there will be hardly any

motion between the two points.

When the distance between the two vectors is smaller

than the value of parameter DELTV in each axis, the

vector shown in the Figure will be omitted, and the

path of the tool will be modified accordingly.

L Note: When parameter DELTV is too high (in

causeless way) the sharp corners with acute

angles may be overcut.

14.5.8 Interferences in Cutter Compensation

It may frequently occur in offset mode that the path of the tool is the opposite of the programmed

one. Under such conditions, the tool may cut into the workpiece contrary to the programmer's

intentions. This phenomenon is referred to as the interference in cutter compensation.

In the case shown in the Figure, after the intersection points

have been computed, a tool path opposite to the

programmed one will be obtained in the execution of

interpolation N2. The hachure area indicates that the tool

cuts in the workpiece.

To avoid this, the control performs an interference check when parameter INTERFER is set to 1.

Now the control will check that the condition -90°#n#+90° is fulfilled for angle n between the

programmed displacement and the one compensated with the radius.