5 The Coordinate Data

39

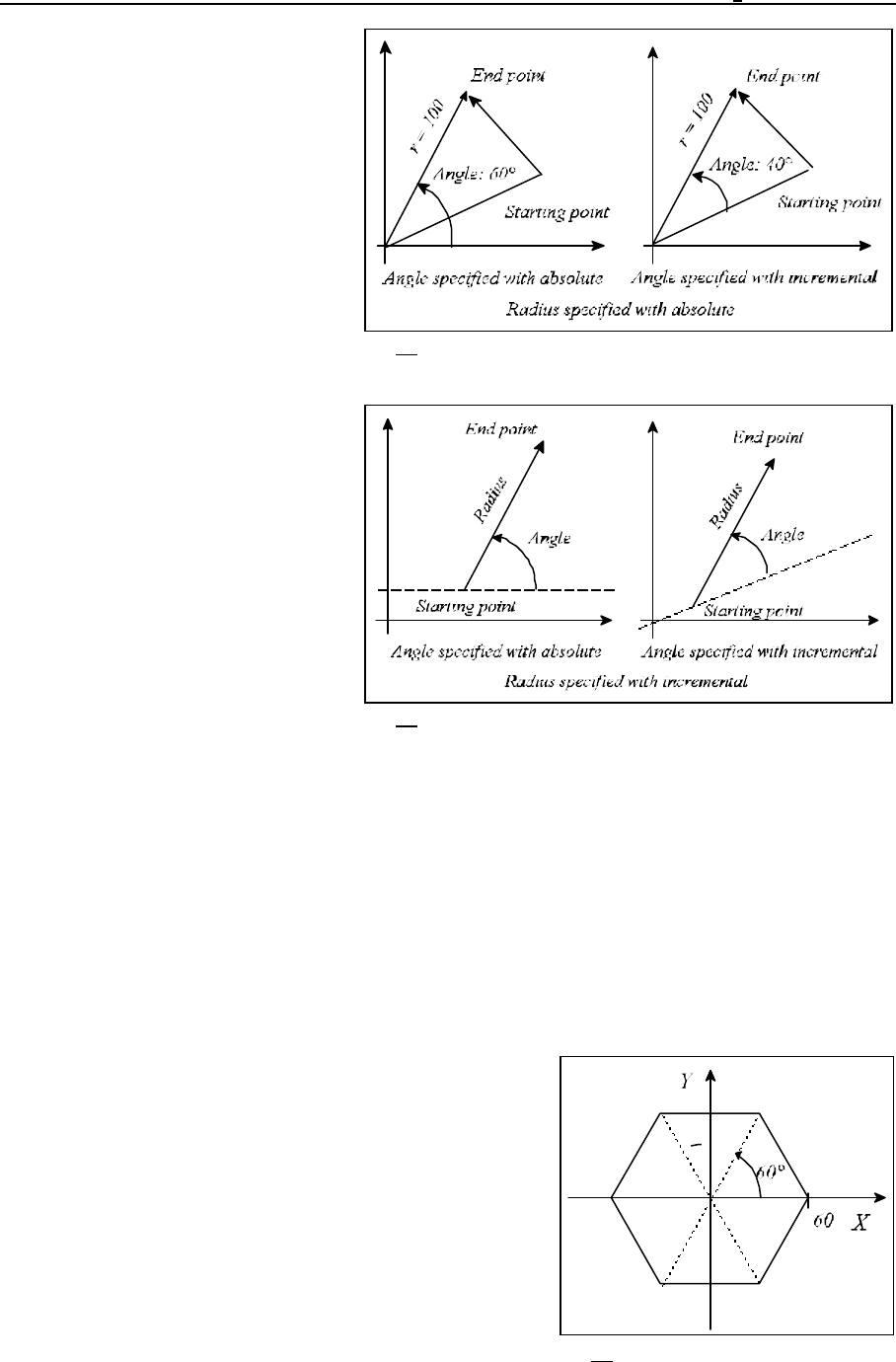

Fig. 5.2-1

Fig. 5.2-2

Fig. 5.2-3

Example:

G90 G16 G01 X100 Y60 F180

Both the radius and the angle are

absolute data, the tool moves to the

point of 100mm; 60°.

G90 G16 G01 X100 YI40 F180

The angle is an incremental data. A

movement by 40° relative to the

previous angular position is moved.

With the radius, specified as an

incremental value, the instantaneous

position of the axes will be the origin

of the polar coordinate system.

A circle can be programmed with

polar coordinate data command

(G16). The circle can be also specified

with the radius and I, J, K as well. In

the latter case, however, the control

will regard addresses I, J, K invariably

as Cartesian data. When the origin of

the current coordinate system

coincides with the center of a circle or

a helix, a multiple turn one can also be

programmed with polar coordinate data specification.

Example:

(G17 G16 G90) G02 X100 Y-990 Z50 R-100

A helix of 2¾ turns has been specified in the above block in counter-clockwise direction of rotation.

In programming a multiple-turn circle, bear in mind that a negative or a positive polar angle has to be

programmed for direction G2 or G3, respectively.

L Notes:

The addresses encountered in the following instructions will not be regarded as polar coordinate

specifications even when state G16 is:

– G10 coordinates encountered in setting instruction,

– G52 coordinate offset,

– G92 coordinate setting,

– G53 positioning in machine coordinate system,

– G68 coordinate rotation,

– G51 scaling on,

– G50.1 programmable mirror image.

An example of milling a hexagon:

N1 G90 G17 G0 X60 Y0 F120

N2 G16 G1 Y60