6

PROGRAMMING

6.2 Using Programs in Normal System Configuration

6 - 4

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

SETUP AND

PROCEDURES BEFORE

OPERATION

5

UTILITY PACKAGE (GX

CONFIGURATOR-TI)

6

PROGRAMMING

7

ONLINE MODULE

CHANGE

8

TROUBLESHOOTING

6.2 Using Programs in Normal System Configuration

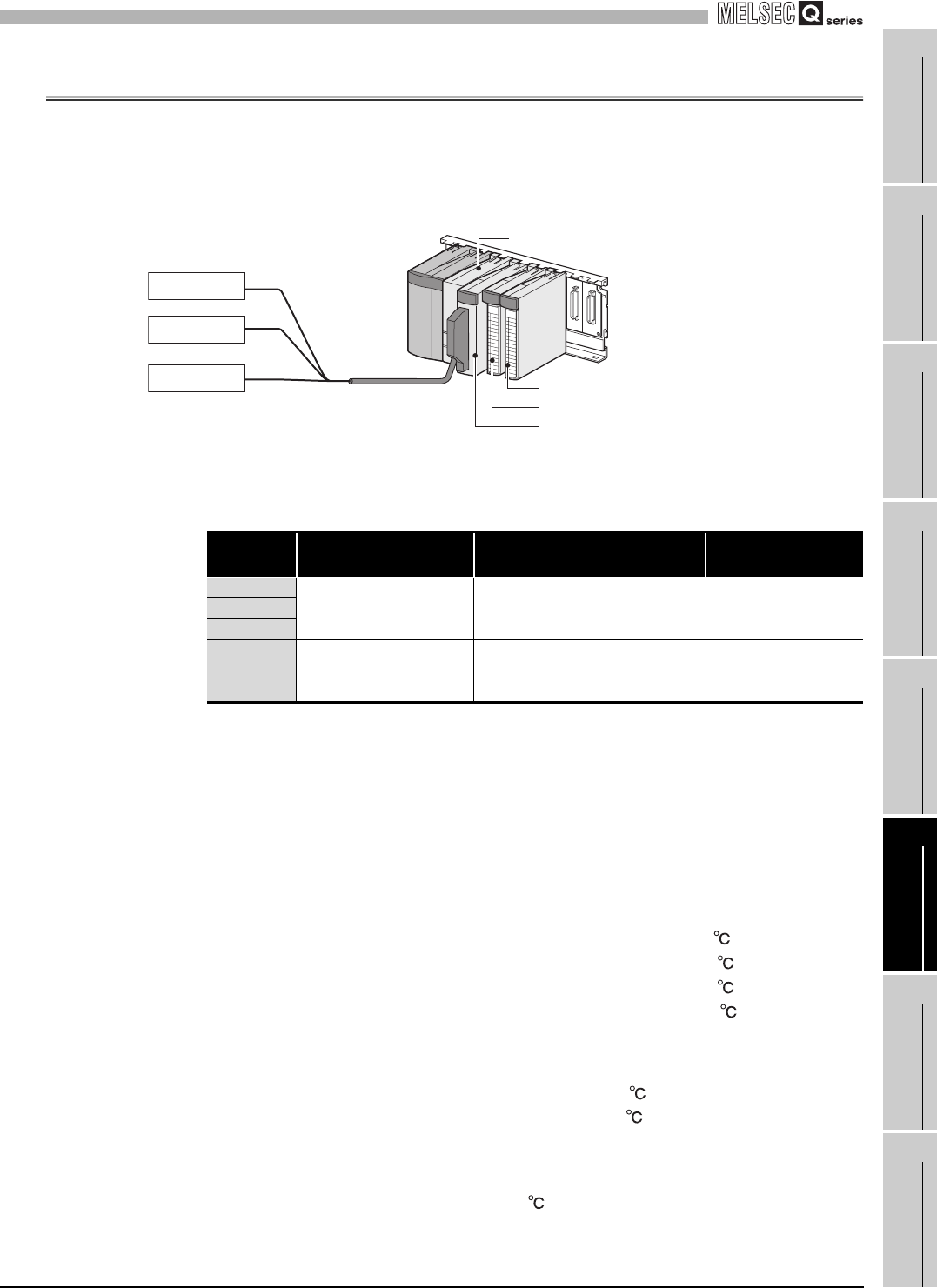

This section describes program examples based on the following system configuratiion

and conditions.

(1) System configuration

Figure 6.2 Example of system configuration

(2) Setting conditions for the intelligent function module switch setting

(3) Programming conditions

(a) Use the following temperature conversion system for each channel.

• CH1: Sampling processing

• CH2: Count average (5 times)

• CH3: Primary delay filter (Time constant 960ms)

(b) Use the following function at each channel.

• CH2: Warning output function

• CH3: Warning output function

(c) Use the following setting for the Conversion setting for disconnection detection of

CH1 to CH3.

• CH1 to CH3: Down scale (-352.0 ) [Default setting]

(d) When a write error occurs, the corresponding error code is output to an output

module in BCD value.

Table 6.1 Setting conditions for the intelligent function module switch setting

Channel

Thermocouple type

(Measurement range)

Offset/gain setting

Cold junction

compensation

CH1

Thermocouple K Factory default setting Available

CH2

CH3

CH4

to

CH8

Not used - -

Process alarm lower lower limit value: 2000 (200 )

Process alarm lower upper limit value: 2050 (205 )

Process alarm upper lower limit value: 2950 (295 )

Process alarm upper upper limit value: 3000 (300 )

Rate alarm warning detection period: 3 times (960ms)

Rate alarm lower limit value: -50 (-5.0 )

Rate alarm upper limit value:50 (+5.0 )

CH1

Thermocouple

CH2

Thermocouple

CH3

Thermocouple

QCPU

QY10 (Y20 to Y2F)

QX10 (X10 to X1F)

Q68TD-G-H02 (X/Y0 to X/YF)