Instruction Bulletin

Appendix A Rev. 3.9

May 2005

A-18 Appendices Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

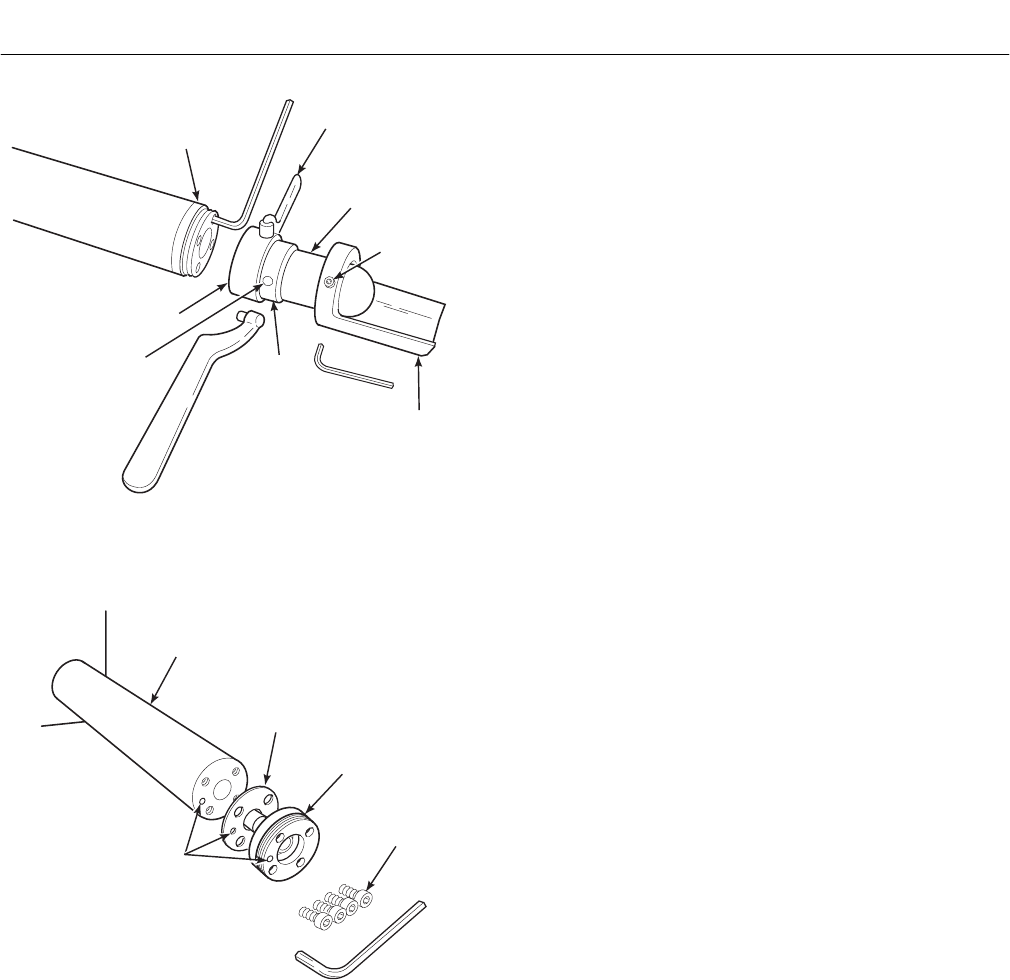

OPTIONAL CERAMIC

DIFFUSION ELEMENT

VEE

DEFLECTOR

HUB

PIN

WRENCH

SETSCREW

RETAINER

CEMENT

PORT

CEMENT

FILLET

21240026

Figure A-19. Removal of Optional Diffusor

and Vee Deflector

PROBE TUBE

(NOT INCLUDED

IN KIT)

SOCKET HEAD

CAP SCREWS

CORRUGATED

SEAL

CELL AND

FLANGE

ASSEMBLY

CALIBRATION GAS

PASSAGE

21240009

Figure A-20. Cell Replacement Kit

e. If contact assembly is damaged, replace

contact and thermocouple according to

paragraph A-13, Replacement of Contact

and Thermocouple Assembly.

f. Remove and discard corrugated seal. Clean

mating faces of probe tube and retainer.

Remove burrs and raised surfaces with

block of wood and crocus cloth. Clean

threads on retainer and hub.

g. Rub a small amount of anti-seize on both

sides of new corrugated seal.

h. Assemble cell and flange assembly, corru-

gated seal, and probe tube. Make sure the

calibration tube lines up with the calibration

gas passage in each component. Apply a

small amount of anti-seize compound to

screw threads and use screws to secure

assembly. Torque to 55 in-lbs (4 N

•

m).

i. Apply anti-seize compound to threads of

cell assembly, hub, and setscrews. Reinstall

hub on cell assembly. Using pin spanner

wrenches, torque to 10 ft-lbs (14 N

•

m). If

applicable, reinstall vee deflector, orienting

apex toward gas flow. Secure with

setscrews and anti-seize compound.

Torque to 25 in-lbs (2.8 N

•

m).

j. On systems equipped with an abrasive

shield, install dust seal gaskets, with joints

180

o

apart.

k. Reinstall probe and gasket on stack flange.

If there is an abrasive shield in the stack,

make sure dust seal gaskets are in place as

they enter 15

o

reducing cone.

l. Turn power on to electronics and monitor

thermocouple output. It should stabilize at

29.3 ±0.2 mV. Set reference air flow at 2 scfh

(56.6 L/hr). After probe stabilizes, calibrate

probe per Instruction Bulletin applicable to

your electronics package. If new components

have been installed, repeat calibration after

24 hours of operation.

A-12 OPTIONAL CERAMIC DIFFUSION

ELEMENT REPLACEMENT

a. General

The diffusion element protects the cell from

particles in process gases. It does not nor-

mally need to be replaced because the vee

deflector protects it from particulate erosion.

In severe environments the filter may be

broken or subject to excessive erosion. Ex-

amine the diffusion element whenever re-

moving the probe for any purpose. Replace

if damaged.