Reference Manual

00809-0100-4665, Rev AA

August 2010

6-5

Rosemount 8732

TRANSMITTER

TROUBLESHOOTING

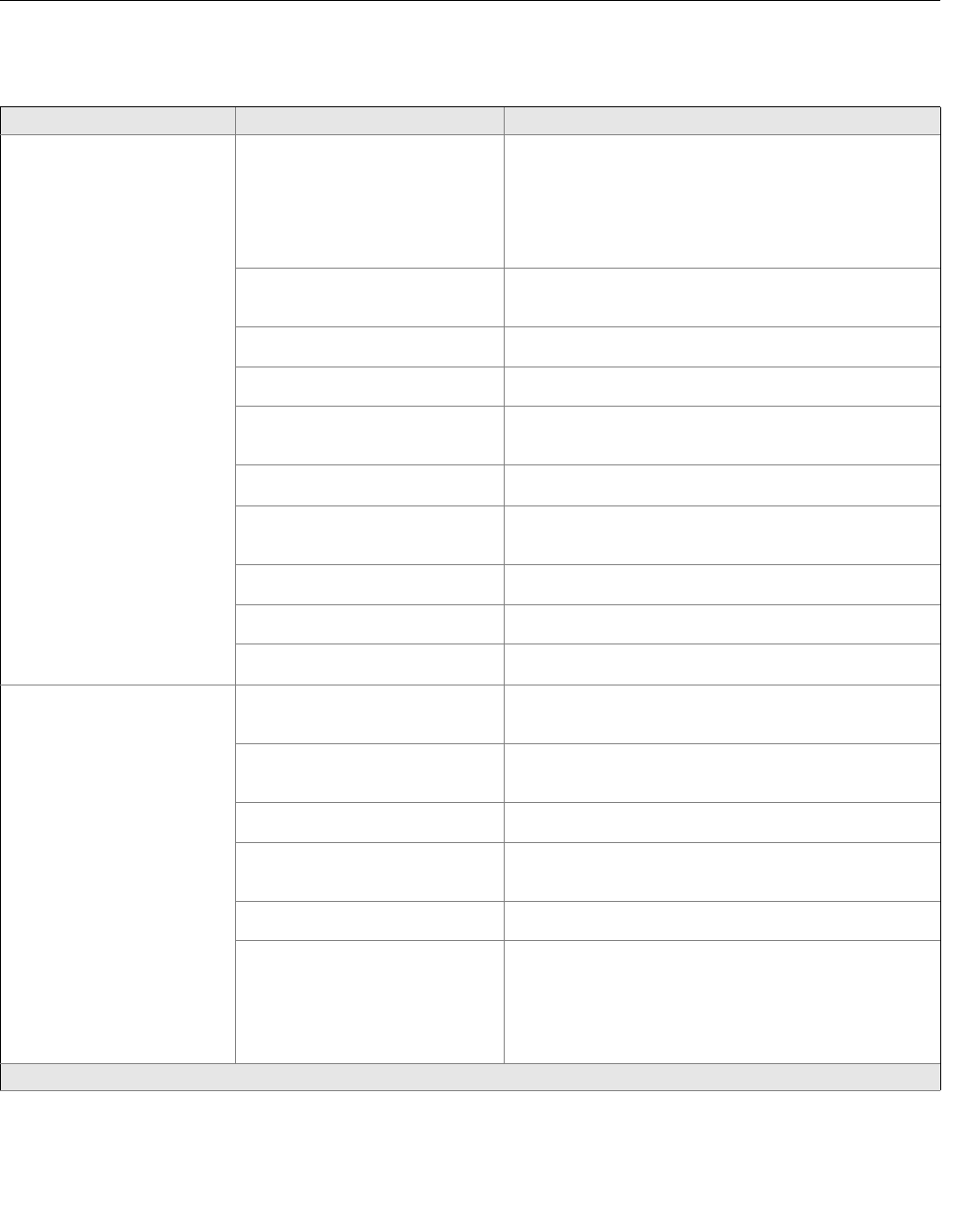

Table 6-4. Advanced Troubleshooting–Rosemount 8732

Symptom Potential Cause Corrective Action

Does not appear to be within

rated accuracy

Transmitter, control system, or other

receiving device not configured

properly

Check all configuration variables for the transmitter, sensor,

communicator, and/or control system

Check these other transmitter settings:

•Sensor calibration number

•Units

•Line size

Electrode Coating Use bulletnose electrodes;

Downsize sensor to increase flow rate above 3 ft/s;

Periodically clean sensor

Air in line Move the sensor to another location in the process line to

ensure that it is full under all conditions.

Moisture problem Perform the sensor Tests A, B, C, and D

(see Table 6-5 on page 6-8)

Improper wiring If electrode shield and signal wires are switched, flow indication

will be about half of what is expected. Check wiring diagrams for

your application.

Flow rate is below 1 ft/s

(specification issue)

See accuracy specification for specific transmitter and sensor

Auto zero was not performed when the

coil drive frequency was changed from

5 Hz to 37 Hz

Set the coil drive frequency to 37 Hz, verify the sensor is full,

verify there is no flow, and perform the auto zero function.

Sensor failure–Shorted electrode Perform the sensor Tests C and D

(see Table 6-5 on page 6-8)

Sensor failure–Shorted or open coil Perform the sensor Tests A and B

(see Table 6-5 on page 6-8)

Transmitter failure Verify transmitter operation with an 8714 Calibration Standard or

replace the electronic board

Noisy Process Chemical additives upstream of

magnetic flowmeter

Complete the Noisy Process Basic procedure. Move injection

point downstream of magnetic flowmeter, or move magnetic

flowmeter.

Sludge flows–Mining/Coal/

Sand/Slurries (other slurries with

hard particles)

Decrease flow rate below 10 ft/s

Styrofoam or other insulating particles

in process

Complete the Noisy Process Basic procedure;

Consult factory

Electrode coating Use replaceable electrodes in Rosemount 8705.

Use a smaller sensor to increase flow rate above 3 ft/s.

Periodically clean sensor.

Air in line Move the sensor to another location in the process line to

ensure that it is full under all conditions.

Low conductivity fluids (below 10

microsiemens/cm)

• Trim electrode and coil wires – see “Conduit Cables” on

page 2-6

• Keep flow rate below 3 FPS

• Integral mount transmitter

• Use 8712-0752-1,3 cable

• Use N0 approval sensor

Advanced Troubleshooting continued on next page