Reference Manual

00809-0100-4665, Rev AA

August 2010

5-11

Rosemount 8732

3. Place the sensor between the flanges. Make sure that the centering

rings are properly placed in the studs. The studs should be aligned

with the markings on the rings that correspond to the flange you are

using.

4. Insert the remaining studs, washers, and nuts.

5. Tighten to the torque specifications shown in Table 5-5. Do not

overtighten the bolts or the liner may be damaged.

NOTE

On the 4- and 6- inch PN 10-16, insert the sensor with rings first and then

insert the studs. The slots on this ring scenario are located on the inside of the

ring.

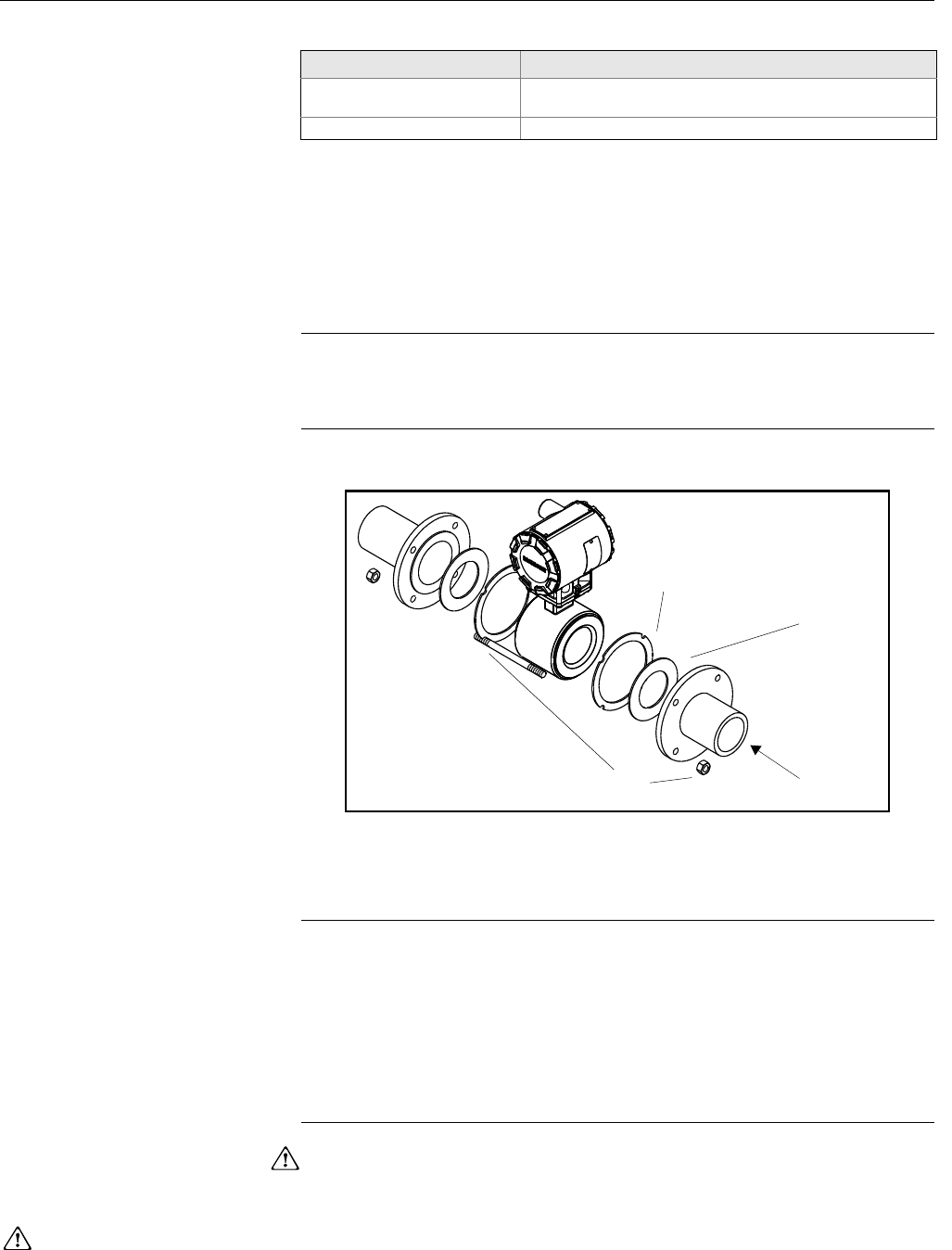

Figure 5-11. Gasket Placement

with Centering Rings

Flange Bolts Sensor sizes and torque values for both Class 150 and Class 300 flanges are

listed in Table 5-5. Tighten flange bolts in the incremental sequence, shown in

Figure 5-10.

NOTE

Do not bolt one side at a time. Tighten each side simultaneously. Example:

1. Snug left

2. Snug right

3. Tighten left

4. Tighten right

Do not snug and tighten the upstream side and then snug and tighten the

downstream side. Failure to alternate between the upstream and downstream

flanges when tightening bolts may result in liner damage.

Always check for leaks at the flanges after tightening the flange

bolts. All sensors require a second torquing 24 hours after initial flange bolt

tightening.

Table 5-4. Stud Specifications

Nominal Sensor Size Stud Specifications

0.15 – 1 inch (4 – 25 mm) 316 SST ASTM A193, Grade B8M

Class 1 threaded mounted studs

1

1

/2 – 8 inch (40 – 200 mm) CS, ASTM A193, Grade B7, threaded mounting studs

Customer-supplied

Gasket

FLOW

Installation, Studs

Nuts and Washers

Centering Rings

See ”Safety Messages” on pages 5-1 and 5-2 for complete warning information.