Reference Manual

00809-0100-4665, Rev AA

August 2010

Rosemount 8732

5-8

NOTE

Do not bolt one side at a time. Tighten each side simultaneously. Example:

1. Snug left

2. Snug right

3. Tighten left

4. Tighten right

Do not snug and tighten the upstream side and then snug and tighten the

downstream side. Failure to alternate between the upstream and downstream

flanges when tightening bolts may result in liner damage.

Always check for leaks at the flanges after tightening the flange bolts. Failure

to use the correct flange bolt tightening methods can result in severe damage.

All sensors require a second torquing 24 hours after initial flange bolt

tightening.

For sensors with ANSI 600# full rated, 900#, 1500#, and 2500# flanges, the

liner is protected from over-compression by the flange design. Standard

flange torque specifications as determined by ANSI and ASME should be

followed. No special precaution is required to prevent liner damage caused by

over torquing. Bolt tightening procedures laid out in this Quick Installation

Guide must still be followed.

To prevent liner damage on any magnetic flowmeter, a flat gasket must be

used. For optimum results on meters with high pressure flanges (ANSI 600#

or above), it is recommended that a flat full face gasket be used.

Under NO circumstances should a spiral wound or flexitallic gasket be used

as this will damage the liner sealing surface.

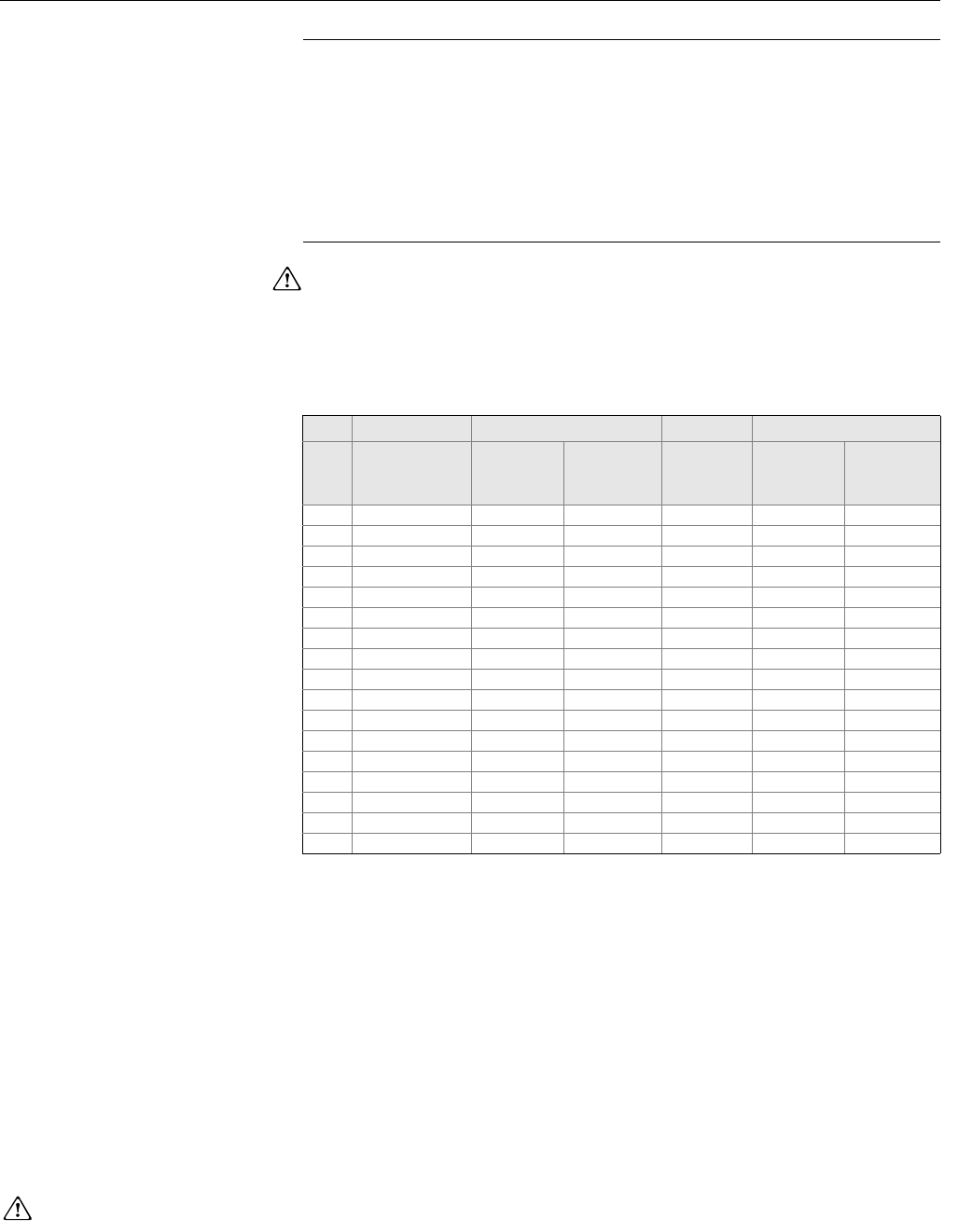

Table 5-1. Flange Bolt Torque Specifications for Rosemount 8705 and 8707

High-Signal Sensors

PTFE/ETFE liner Polyurethane liner

Size

Code

Line Size

Class 150

(pound-feet)

Class 300

(pound-feet)

Class 600

(1)

(Derated to

1000 psi)

(1) Derated available with PTFE lining only.

Class 150

(pound-feet)

Class 300

(pound-feet)

005 0.5-in. (15 mm) 8 8 8 8 -

010 1- in. (25 mm) 8 12 13 13 -

015 1.5-in. (40 mm) 13 25 29 29 7

020 2-in. (50 mm) 19 17 20 20 14

030 3-in. (80 mm) 34 35 41 41 23

040 4-in. (100 mm) 26 50 68 68 17

060 6-in. (150mm) 45 50 77 77 30

080 8-in. (200 mm) 60 82 121 121 42

100 10-in. (250 mm) 55 80 129 129 40

120 12-in. (300 mm) 65 125 146 146 55

140 14-in. (350 mm) 85 110 194 194 70

160 16-in. (400 mm) 85 160 274 274 65

180 18-in. (450 mm) 120 170 432 432 95

200 20-in. (500 mm) 110 175 444 444 90

240 24-in. (600 mm) 165 280 731 731 140

300 30-in. (750 mm) 195 375 - - 165

360 36-in. (900 mm) 280 575 - - 245

See ”Safety Messages” on pages 5-1 and 5-2 for complete warning information.