Reference Manual

00809-0100-4665, Rev AA

August 2010

5-7

Rosemount 8732

INSTALLATION

(FLANGED SENSOR)

The following section should be used as a guide in the installation of the

flange-type Rosemount 8705 and Rosemount 8707 High-Signal Sensors.

Refer to page 5-10 for installation of the wafer-type Rosemount 8711 Sensor.

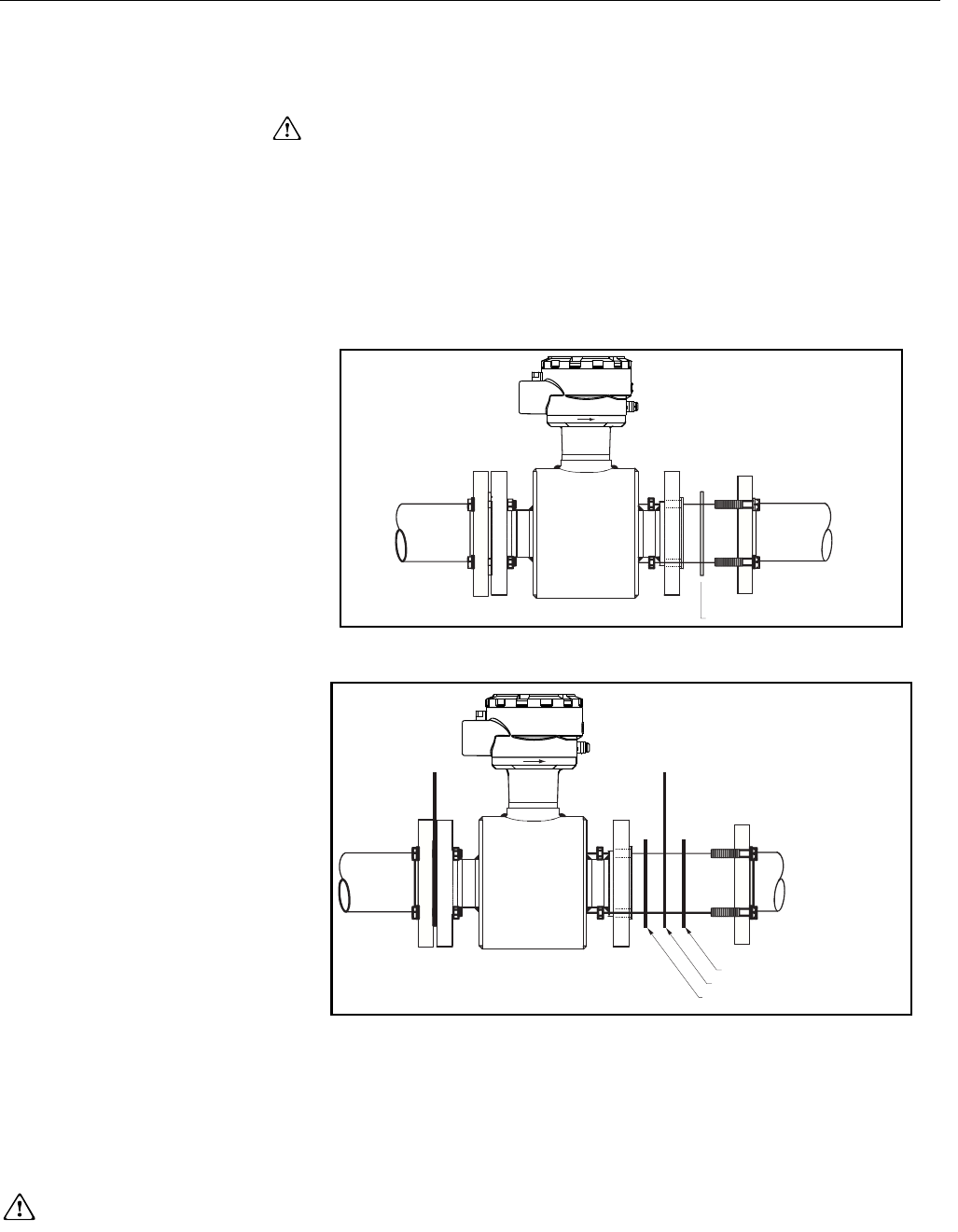

Gaskets The sensor requires a gasket at each of its connections to adjacent devices or

piping. The gasket material selected must be compatible with the process fluid and

operating conditions. Metallic or spiral-wound gaskets can damage the

liner. If the gaskets will be removed frequently, protect the liner ends. All other

applications (including sensors with lining protectors or a grounding electrode)

require only one gasket on each end connection, as shown in Figure 5-8. If

grounding rings are used, gaskets are required on each side of the grounding

ring, as shown in Figure 5-9.

Figure 5-8. Gasket Placement

Figure 5-9. Gasket Placement

with Non-attached Grounding

Rings

Flange Bolts Suggested torque values by sensor line size and liner type are listed in Table

5-1 on page 5-8 for ASME B16.5 (ANSI) flanges and Table 5-2 and Table 5-3

for DIN flanges. Consult the factory for other flange ratings. Tighten flange

bolts in the incremental sequence as shown in Figure 5-10. See Table 5-1 and

Table 5-2 for bolt sizes and hole diameters.

See ”Safety Messages” on pages 5-1 and 5-2 for complete warning information.

Gasket (Supplied by user)

Gasket (Supplied by user)

Grounding Ring

Gasket (Supplied by user)