Reference Manual

00809-0100-4665, Rev AA

August 2010

6-3

Rosemount 8732

DIAGNOSTIC

MESSAGES

Problems in the magnetic flowmeter system are usually indicated by incorrect

output readings from the system, error messages, or failed tests. Consider all

sources in identifying a problem in your system.

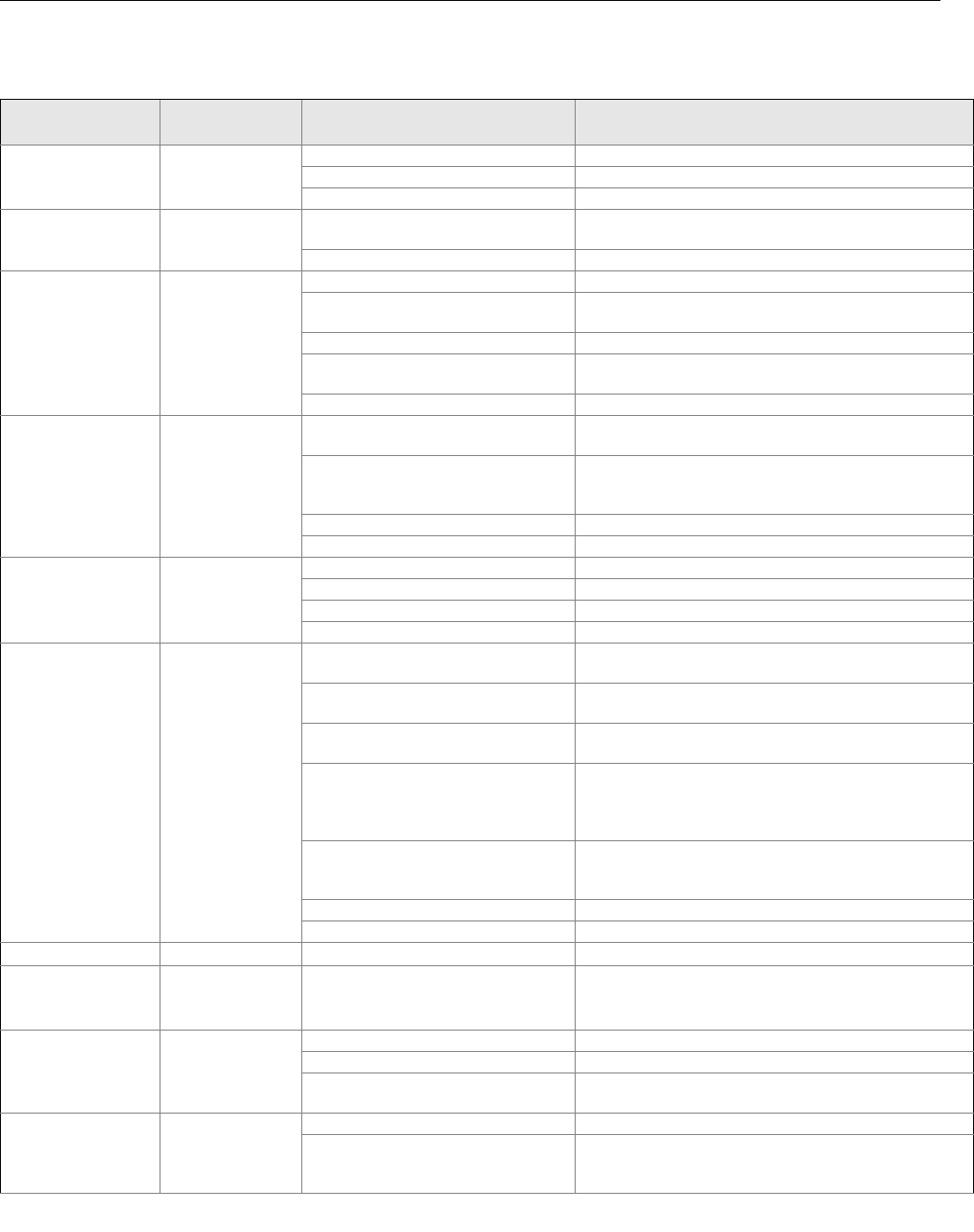

Table 6-1. Rosemount 8732 Basic Diagnostic Messages

Message

Local Display Error

Message (English)

Potential Cause Corrective Action

“Profibus Not

Communicating”

Profibus Not

Communicating

Profibus segment is disconnected Connect the Profibus segment

Profibus segment power missing Verify the segment Profibus voltage

Electronics failure Replace electronics

“Sensor Processor Not

Communicating”

Sensor Comm Err Transmitter input power (AC/DC) is not

connected

Connect the input power. If the LCD displays a message,

the input power is applied

Electronics failure Replace electronics

“Empty Pipe Detected” Empty Pipe Empty Pipe None - message will clear when pipe is full

Wiring Error Check that wiring matches appropriate wiring diagrams -

see Appendix E: Universal Sensor Wiring Diagrams

Electrode Error Perform sensor tests C and D (see Table 6-5 on page 6-8)

Conductivity less than 5 microsiemens

per cm

Increase Conductivity to greater than or equal to 5

microsiemens per cm

Intermittent Diagnostic Adjust tuning of Empty Pipe parameters

“Coil Drive Open

Circuit”

Coil Open Ckt Improper wiring Check coil drive wiring and sensor coils

Perform sensor test A - Sensor Coil

Other manufacturer’s sensor Change coil current to 75 mA

Perform a Universal Auto Trim to select the proper coil

current

Circuit Board Failure Replace Rosemount 8732 Electronics

Coil Circuit OPEN Fuse Return to factory for fuse replacement

“Auto Zero Failure

(Cycle power to clear

messages, no changes

were made)”

Auto Zero Fail Flow is not set to zero Force flow to zero, perform autozero

Unshielded cable in use Change wire to shielded cable

Moisture problems See moisture problems in “Accuracy Section”

Empty pipe is present Fill sensor with process fluid

“Universal Trim Failure” Univ Trim Fail No flow in pipe while performing

Universal Auto Trim

Establish a known flow in sensor, and perform Universal

Auto-Trim calibration

Wiring error Check that wiring matches appropriate wiring diagrams -

see “Universal Sensor Wiring Diagrams” on page E-1

Flow rate is changing in pipe while

performing Universal Auto-Trim routine

Establish a constant flow in sensor, and perform Universal

Auto-Trim calibration

Flow rate through sensor is

significantly different than value

entered during Universal Auto-Trim

routine

Verify flow in sensor and perform Universal Auto-Trim

calibration

Incorrect calibration number entered

into transmitter for Universal Auto-Trim

routine

Replace sensor calibration number with

1000005010000001

Wrong sensor size selected Correct sensor size setting - See “Line Size” on page 3-9

Sensor failure Perform sensor tests C and D (see Table 6-5 on page 6-8)

“Electronics Failure” Electronics Fail Electronics self check failure Replace Electronics

“Electronics

Temperature Out of

Range”

Temp Out of Rng Ambient temperature exceeded the

electronics temperature limits

Move transmitter to a location with an ambient

temperature range of -40 to 165 °F (-40 to 74 °C)

“Reverse Flow

Detected”

Reverse Flow Electrode or coil wires reverse Verify wiring between sensor and transmitter

Flow is reverse Turn ON Reverse Flow Enable to read flow

Sensor installed backwards Re-install sensor correctly, or switch either the electrode

wires (18 and 19) or the coil wires (1 and 2)

“Sensor Hi Limit

Exceeded”

Flow >Sens limit Flow rate is greater than 43 ft/sec Lower flow velocity, increase pipe diameter

Improper wiring Check coil drive wiring and sensor coils

Perform sensor test A - Sensor Coil (see Table 6-5 on

page 6-8)