64

Reference Manual

00809-0100-4102, Rev AA

Section 5: Operation and Maintenance

May 2013

Operation and maintenance

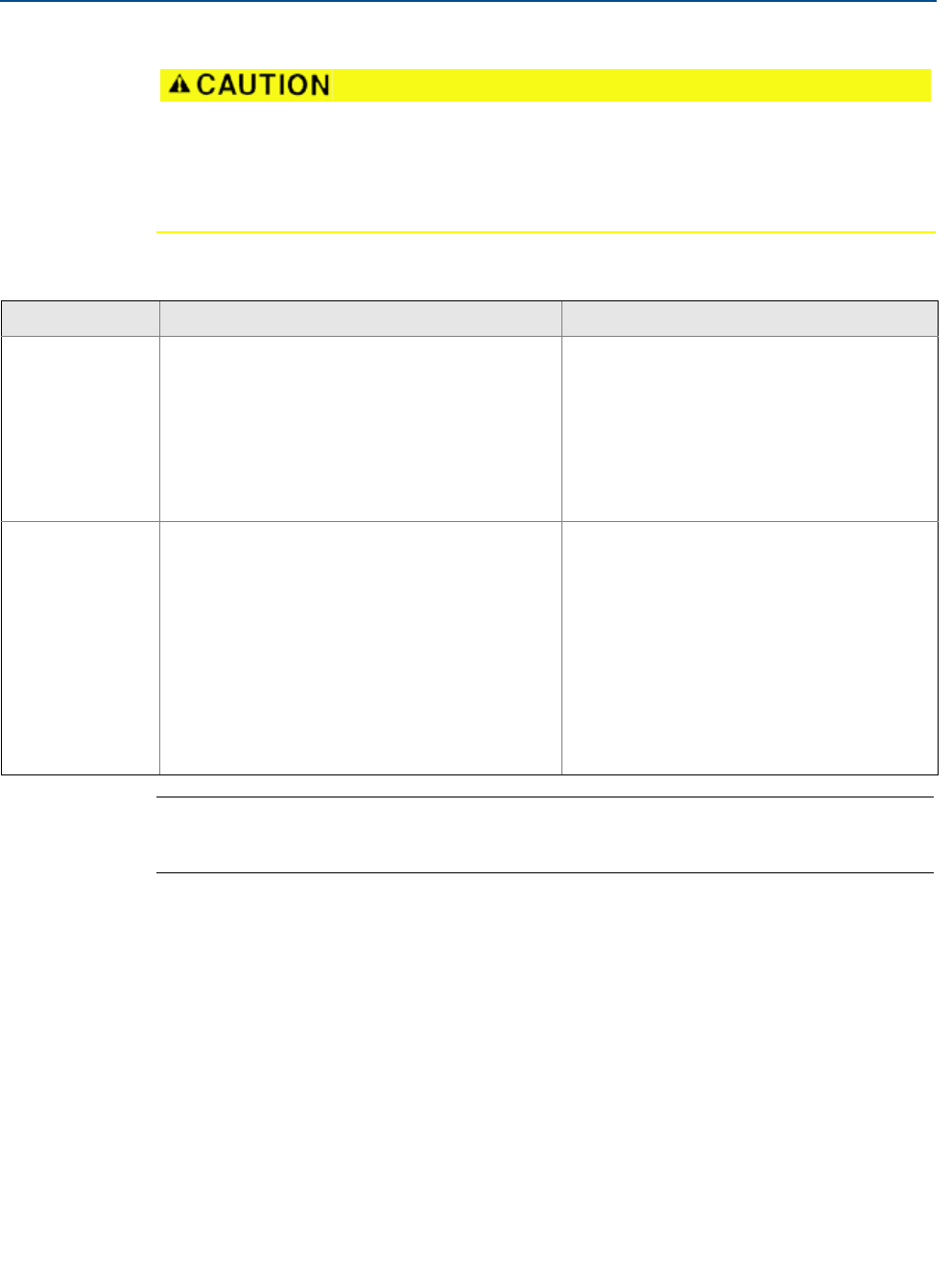

Table 5-1. Recommended Calibration Tasks

Note:

For 2051CA, 2051TA range 0 and range 5 devices, an accurate absolute pressure source is

required.

5.3.1 Determining necessary Sensor Trims

Bench calibrations allow for calibrating the instrument for its desired range of operation.

Straight forward connections to pressure source allow for a full calibration at the planned

operating points. Exercising the Transmitter over the desired pressure range allows for

verification of the output value. “Sensor Trim” on page 68 discusses how the trim operations

change the calibration. It is possible to degrade the performance of the transmitter if a trim is

done improperly or with inaccurate equipment. The transmitter can be set back to factory

settings using the Recall Factory Trim command in “Recall Factory Trim—Sensor Trim” on

page 70.

Absolute pressure transmitters (2051CA and 2051TA) are calibrated at the factory.

Trimming adjusts the position of the factory characterization curve. It is possible to

degrade performance of the transmitter if any trim is done improperly or with inaccurate

equipment.

Transmitter Bench Calibration Tasks Field Calibration Tasks

2051CD

2051CG

2051L

2051TG, Range

1-4

1. Set output configuration parameters:

a. Set the range points.

b. Set the output units.

c. Set the output type.

2. Optional: Perform a sensor trim.

(Accurate pressure source required.)

1. Reconfigure parameters if

necessary.

2. Zero trim the transmitter to

compensate for mounting effects

or static pressure effects.

2051CA

2051TA

2051TG, Range 5

1. Set output configuration parameters:

a. Set the range points.

b. Set the output units.

c. Set the output type.

2. Optional: Perform a sensor trim if

equipment available (accurate

absolute pressure source required),

otherwise perform the low trim value

section of the sensor trim procedure.

1. Reconfigure parameters if

necessary.

2. Perform low trim value section of

the sensor trim procedure to

correct for mounting position

effects.