SECTION 24—ALARM TEST

Part No 1110538 93 Platinum™Series

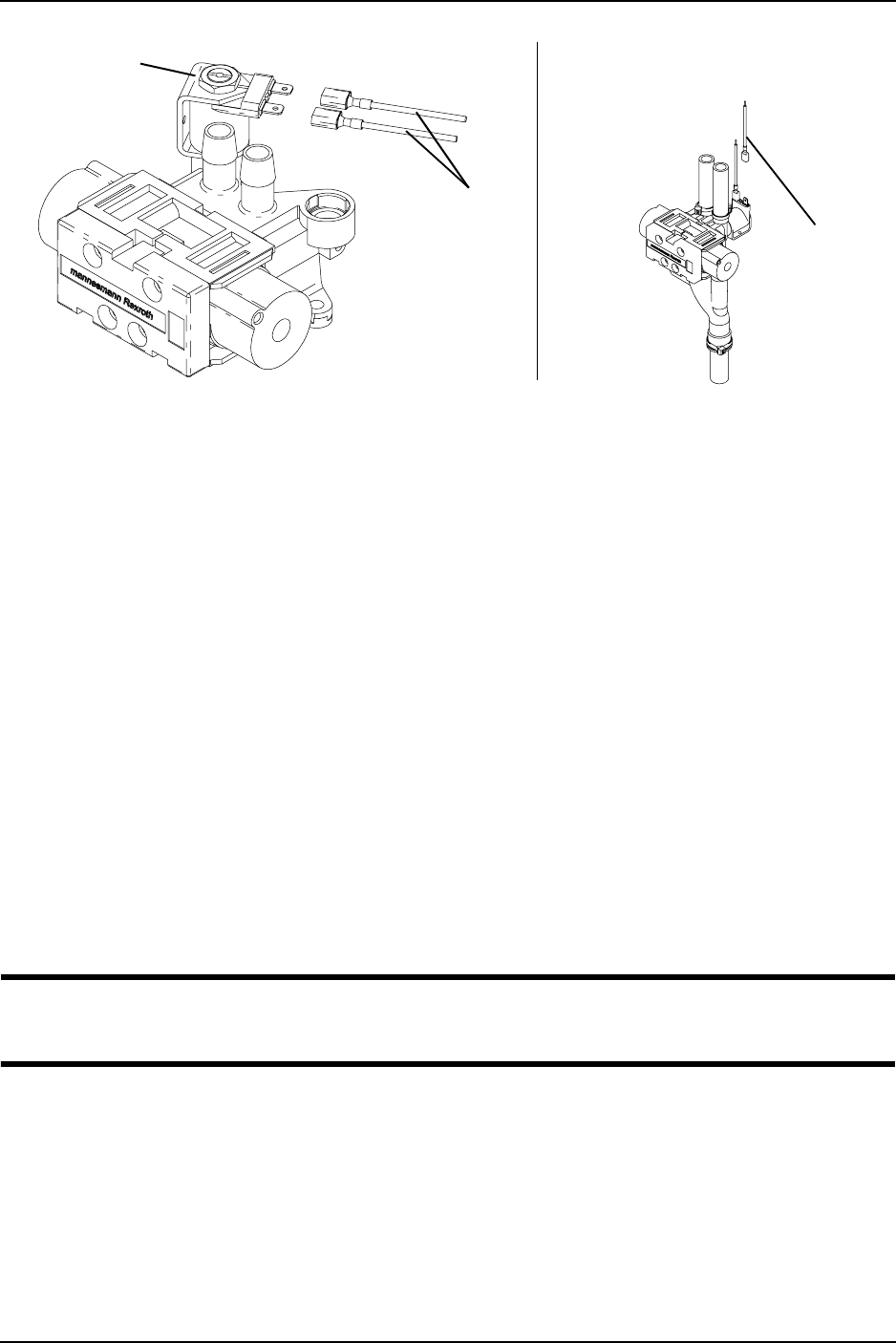

FIGURE 24.2 High Pressure Test

Oxygen Sensor

NOTE: For this procedure, refer to FIGURE 24.3.

Alarm sequence occurs when concentration levels fall below a preset value, typically 73%

± 3% or 85% ± 2%. This failure indicates a catastrophic failure of any component

mechanical or electrical.

1. Turn unit on ( ). Set output flow at 5 L/min for 5 liter units and 10 L/min. for 10 liter

units.

2. Monitor the O

2

level.

3. With the O

2

level greater than 85% after five minutes, the GREEN panel indicator light

will remain illuminated.

4. Slowly adjust flow beyond maximum rated flow until you can achieve a concentration

level greater than 75% but less than 84%. Within 30 minutes the YELLOW panel

indicator light will illuminate and the unit will continue to run.

5. Clamp off the 1/8-inch oxygen sensor tubing between the oxygen sensor and the

product tank regulator.

ƽ WARNING

Use care not to cut oxygen sensor tubing when clamping the oxygen sensor tubing.

6. Within 30 minutes, the Oxygen Sensor Alarm should activate and the RED panel light

indicator will illuminate. The compressor will shut down with the alarm.

Orange Wires

(Only one wire

needs to be

removed)

Main Valve

Coil

DETAIL “A” - PLATINUM 5

DETAIL “B” - PLATINUM XL

AND PLATINUM10

Orange

Wire

I

/