Instruction Manual

245364-V

May 2002

4-2 Theory Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755A

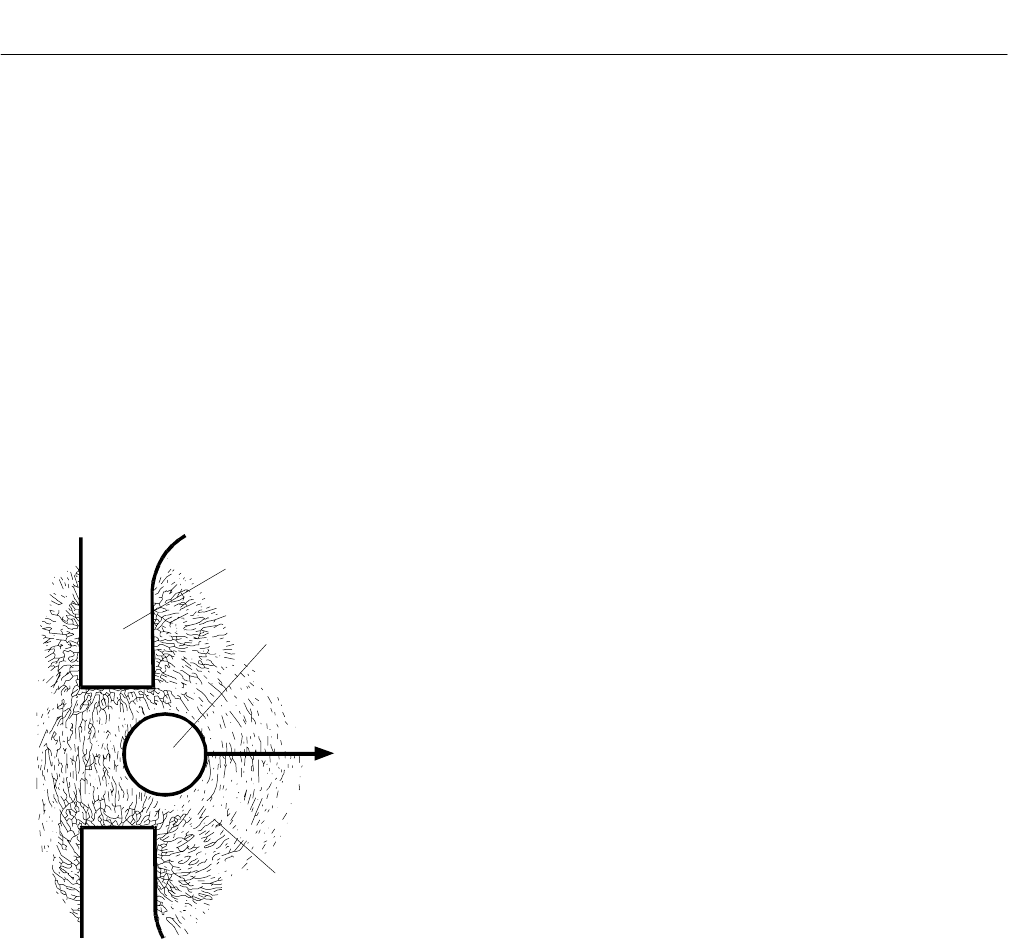

Shaded

Pole

Piece

Sphere

(Magnetic Susceptibility = k

o

)

F

k

Sample Gas

(Magnetic Susceptibility = k

)

Note:

As percentage of oxygen in sample gas increases,

displacement force (F

k

) increases.

Where:

c = A function of the magnetic field

strength and gradient

k = Magnetic susceptibility of the

surrounding gas

k

o = Magnetic susceptibility of the

sphere

The forces exerted on the two spheres of

the test body are thus a measure of the

magnetic susceptibility of the sample and,

therefore, of its oxygen content.

Figure 4-1. Spherical Body in Non-Uniform

Magnetic Field

b. Physical Configuration of

Detector/Magnet Assembly

As shown in Figure 4-3A (page 4-4), the

Detector/Magnet Assembly consists of

three major components; the magnet

assembly, the detector assembly and the

optical bench assembly.

The magnet assembly includes a sample

pre-heating coil. It is connected into the

sample line upstream from the detector

and is heated to approximately the same

temperature as the detector assembly.

For convenience in servicing, the detector

and the optical bench are self-aligning

assemblies that utilize slip-on sample

connections and plug-in electrical

connections.

Within the detector assembly, Figure 4-3B

(page 4-4), the incoming preheated

sample passes through an integral 5

micron diffusion screen. It protects the

test body by preventing entry of

particulate matter and/or entrained liquid

mist. Additionally, the screen isolates the

test body from flow effects, ensuring that

instrument readout is relatively

independent of flow rate within the

optimum range of 200 to 300 cc/min.

At the rear of the detector are an integral

temperature sensor (RT1) and an integral

heater (HR2). Another heater (HR1) is

attached to the magnet. Sensor RT1

provides the input signal to the detector

temperature control circuit of the Case

Board assembly, Section 4-3c (page 4-7).

This circuit controls application of

electrical power to both HR1 and Hr2.

On the optical bench assembly, Figure

4-3C (page 4-4), the source lamp and the

photocell plate are externally accessible,

permitting convenient replacement.