Instruction Manual

245364-V

May 2002

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755A

755A

Analyzer

Recorder

Controller

Remote

Indicator

+

-

+

-

+

-

+

-

mA

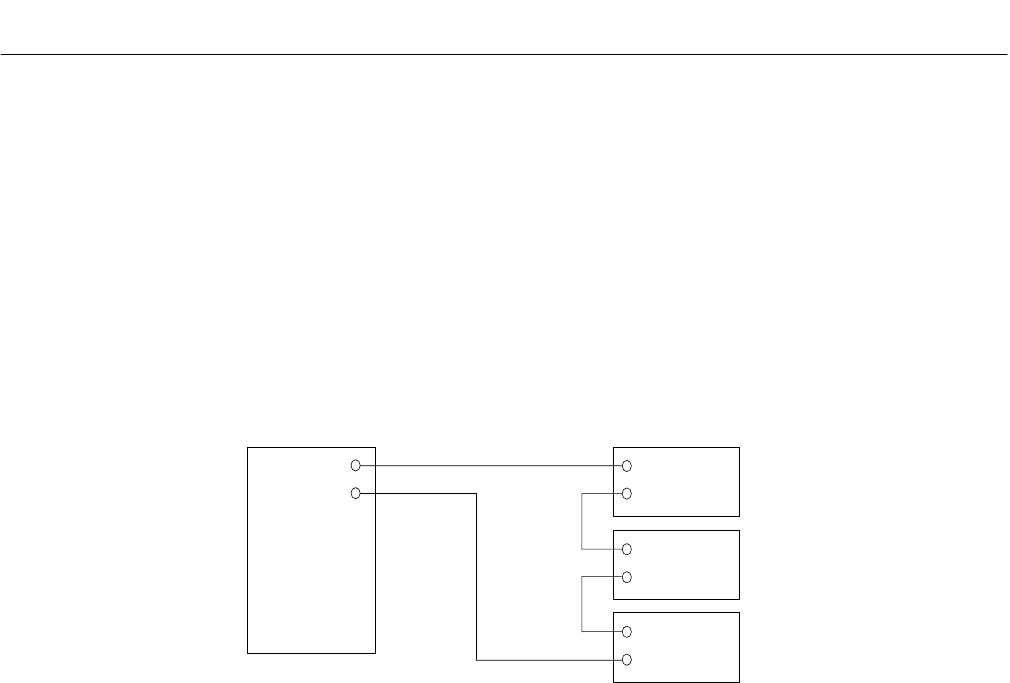

d. Isolated Current Output (Optional)

1. Verify that the Current Output Board

appropriate to desired output is

properly in place. See Figure 2-2,

page 2-3. If originally ordered with

analyzer, the board is factory

installed.

2. On TB2, Figure 2-1 (page 2-2),

connect leads of shielded recorder

cable to "MA+" and "-" terminals.

3. Connect free end of output cable to

input terminals of recorder or other

current actuated device, making sure

that polarity is correct. If two or more

current-actuated devices are to be

used, they must be connected in

series as shown in Figure 2-4 below

Total resistance of all output devices and

associated interconnection cable must not

exceed 850 ohms.

Current and voltage outputs may be

utilized simultaneously, if desired.

Figure 2-4. Model 755A Connected to Drive Several Current-Activated Output Devices

e. Output Connections for Dual Alarm

Option

If so ordered, the analyzer is factory-

equipped with alarm output. Alternatively,

the alarm feature is obtainable by

subsequent installation of the 618083

Alarm Relay Kit.

f. Alarm Output Connections

The alarm output provides two sets of

relay contacts for actuation of alarm

and/or process control functions. Leads

from the (customer-supplied) external

alarm system connect to terminals on the

638254 Alarm Relay Assembly (see

Figure 2-1, page 2-2).

Note the following recommendations:

1. A line fuse should be installed in the

line between the (customer-supplied)

power supply and the alarm relay

terminals on the Alarm Relay

Assembly.

2. If the alarm contacts are connected to

any device that produces radio

frequency interference (RFI), it should

be arc-suppressed. Rosemount

Analytical Arc Suppression (PN

858728) is recommended.

3. If possible, the analyzer should

operate on a different AC power

source to avoid RFI.

4. Do not allow internal cable service

loop to touch the detector assembly

or associated inlet and outlet tubing.

This precaution ensures against

possible transmission of mechanical

vibration through the cable to the

detector, which can cause loss of

accuracy.