Principles of Operation Teledyne API T802 Paramagnetic O

2

Analyzer Operation Manual

224

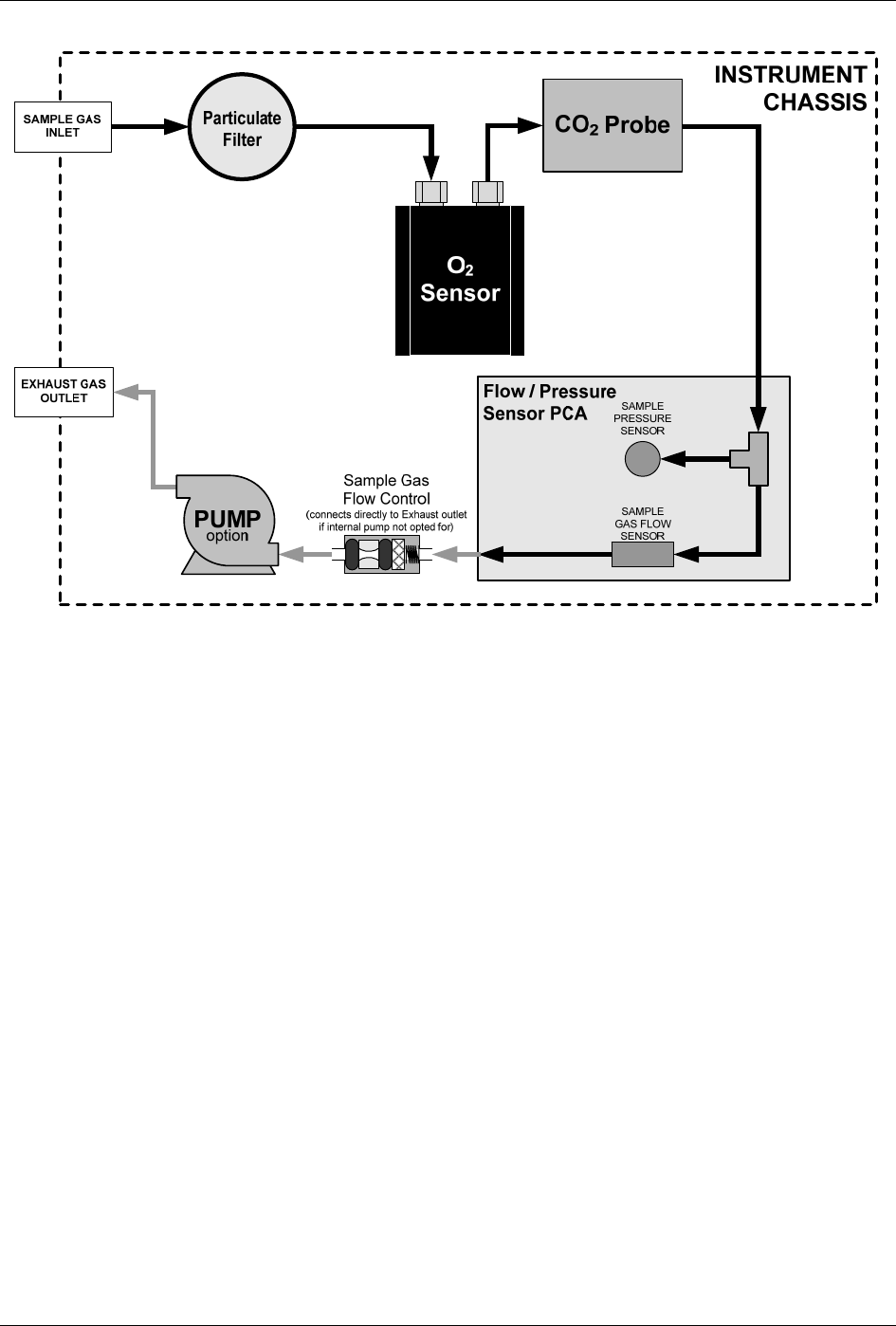

Figure 12-5: T802 – Internal Pneumatic Flow with CO

2

Sensor Option

12.4. FLOW RATE CONTROL

To maintain a constant flow rate of the sample gas through the instrument, the

T802 uses a special flow control assembly located in the exhaust gas line just

before the optional internal pump or connected to the rear panel if using an

external pump. These assemblies consist of:

A critical flow orifice.

Two o-rings: Located just before and after the critical flow orifice, the o-rings

seal the gap between the walls of assembly housing and the critical flow

orifice.

A spring: Applies mechanical force needed to form the seal between the o-

rings, the critical flow orifice and the assembly housing.

A sintered filter: Removes particulates to prevent clogging the orifice

12.4.1. CRITICAL FLOW ORIFICE

The most important component of this flow control assembly is the critical flow

orifice.

Critical flow orifices are a remarkably simple way to regulate stable gas flow

rates. They operate without moving parts by taking advantage of the laws of fluid

dynamics. By restricting the flow of gas though the orifice, a pressure differential

is created. This pressure differential combined with the action of the analyzer’s

pump draws the gas through the orifice.

07275B DCN6418