Section II Operating Instructions Teledyne API T802 Paramagnetic O

2

Analyzer Operation Manual

140

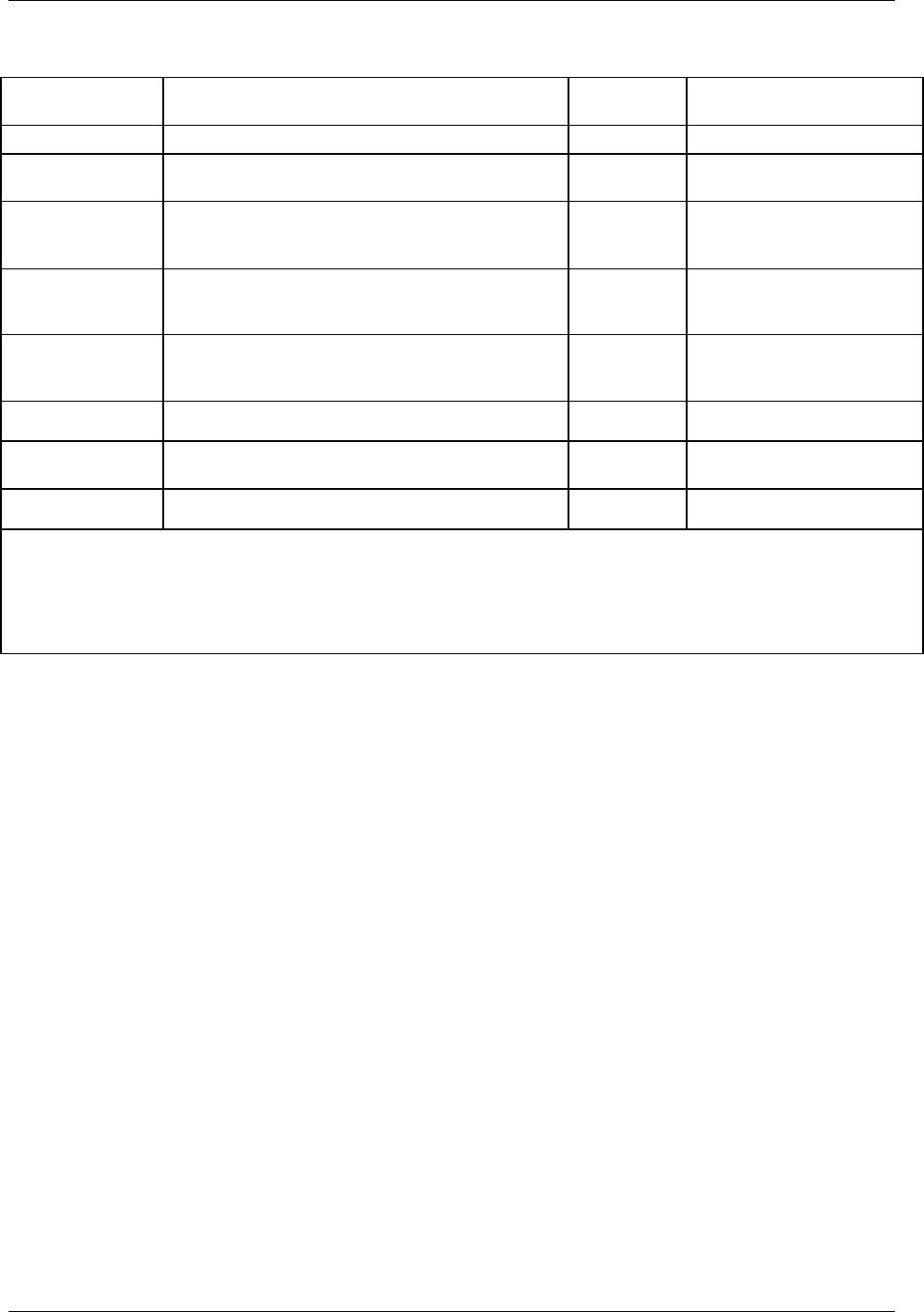

Table 7-2: DAS Data Channel Properties

PROPERTY DESCRIPTION

DEFAULT

SETTING

SETTING RANGE

NAME

The name of the data channel.

“NONE”

Up to 6 letters or digits

1

TRIGGERING

EVENT

The event that triggers the data channel to measure

and store the datum

ATIMER

Any available event

(see Appendix A-5).

NUMBER AND

LIST OF

PARAMETERS

A User-configurable list of data types to be

recorded in any given channel.

1

(PMTDET)

Any available parameter

(see Appendix A-5).

REPORT PERIOD

The amount of time between each channel data

point.

000:01:00

(1 hour)

000:00:01 to

366:23:59

(Days:Hours:Minutes)

NUMBER OF

RECORDS

The number of reports that will be stored in the data

file. Once the limit is exceeded, the oldest data is

over-written.

100

1 to 30,000 (max), limited

by available storage

space.

2

RS-232 REPORT

Enables the analyzer to automatically report

channel values to the RS-232 ports.

OFF

OFF or ON

CHANNEL

ENABLED

Enables or disables the channel. Allows a channel

to be temporarily turned off without deleting it.

ON

OFF or ON

CAL HOLD OFF

Disables sampling of data parameters while

instrument is in calibration mode.

3

OFF

OFF or ON

1

More with APICOM, but only the first six are displayed on the front panel).

2

For information regarding the maximum number of channels, parameters, and records and how to calculate the file size for each data

channel, refer to the DAS manual downloadable from the TAPI website at http://www.teledyne-api.com/manuals/ under Special

Manuals.

3

When enabled records are not recorded until the DAS HOLDOFF period is passed after calibration mode. DAS HOLDOFF SET in the

VARS menu (see Section

5.8.)

7.1.2. DEFAULT DAS CHANNELS

CONC: Samples O

2

concentration at one minute intervals and stores an average

every hour with a time and date stamp. Readings during calibration and

calibration HOLD OFF are not included in the data. By default, the last 800

hourly averages are stored.

PNUMTC: Collects sample flow and sample pressure data at five-minute

intervals and stores an average once a day with a time and date stamp. This data

is useful for monitoring the condition of the pump and critical flow orifice

(sample flow) and the sample filter (clogging indicated by a drop in sample

pressure) over time to predict when maintenance will be required. The last 360

daily averages (about 1 year) are stored.

CALDAT: Data channel logs new slope and offset of O

2

measurements each

time a zero or span calibration is performed and the result changes the value of

the slope (triggering event: SLPCHG). The O

2

stability (to evaluate if the

calibration value was stable) as well as the converter efficiency (for trend

reference) are also stored.

This data channel will store data from the last 200 calibrations and can be

used to document analyzer calibration; it also is useful for detecting trends in

slope and offset (instrument response) when performing predictive

diagnostics as part of a regular maintenance schedule.

07275B DCN6418