Instruction Manual

IB-106-340 Rev. 3.0

December 2003

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Oxymitter 4000

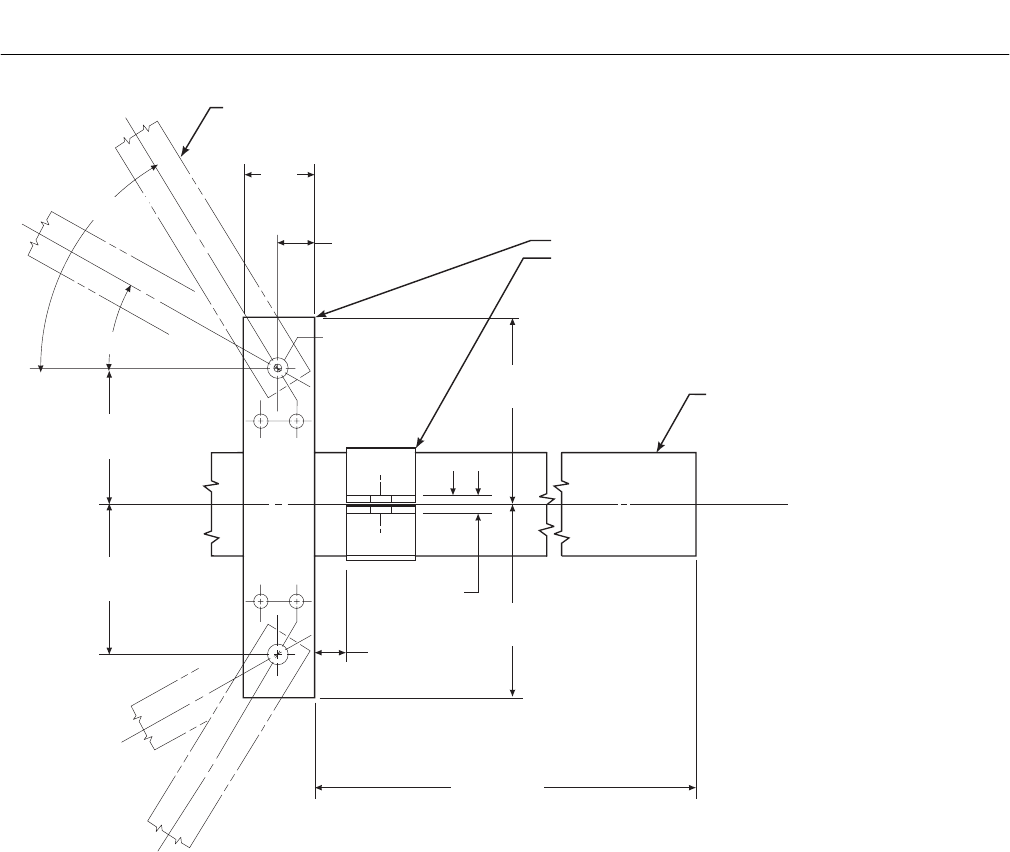

BRACE BARS

(NOT BY ROSEMOUNT)

2.00

(51)

NOTE: DIMENSIONS IN INCHES WITH

MILLIMETERS IN PARETHESES.

VERTICAL BRACE CLAMP ASSY.

ABRASIVE SHIELD

HORIZONTAL BRACE CLAMP ASSY.

(BOTH BRACE CLAMP ASSEMBLIES ARE THE SAME.

INSTALLATION AND LOCATION OF CLAMP ASSEMBLIES

AND BRACE BARS TO BE DONE IN FIELD.)

BY ROSEMOUNT

}

2 HOLES - 0.625

(16) DIA FOR

0.50 (12) DIA

BOLT

NOTE: BRACING IS FOR VERTICAL AND HORIZONTAL OXYMITTER 4000

1.00

(25) MAX

0.375

(10)

1.00

(25)

4.12

(105)

4.12

(105)

60 MAX

o

30 MIN

o

5.62

(143)

5.62

(143)

36.00 (914)

INSTALLATION. EXTERNAL BRACING REQUIRED FOR 9 FT THROUGH 18 FT

(2.75 M THROUGH 5.49 M) PROBES AS SHOWN ABOVE.

36920003

Figure 2-7. Oxymitter 4000 Abrasive Shield Bracing Installation

5. In vertical installations, ensure the sys-

tem cable drops vertically from the

Oxymitter 4000 and the conduit is

routed below the level of the electron-

ics housing. This drip loop minimizes

the possibility that moisture will dam-

age the electronics (Figure 2-9).

6. If the system has an abrasive shield,

check the dust seal gaskets. The joints

in the two gaskets must be staggered

180°. Also, make sure the gaskets are

in the hub grooves as the Oxymitter

4000 slides into the 15° forcing cone in

the abrasive shield.

7. Insert probe through the opening in the

mounting flange and bolt the unit to the

flange. When probe lengths selected

are 9 to 18 ft (2.74 to 5.49 m), special

brackets are supplied to provide addi-

tional support for the probe inside the

flue or stack (Figure 2-7).

NOTE

If process temperatures will exceed

392°F (200°C), use anti-seize com-

pound on stud threads to ease future

removal of Oxymitter 4000. For probe

temperatures that will exceed 185°F

(85°C), we recommend the remote

mounted electronics option.