Reference Manual

00809-0100-4663, Rev BA

January 2010

B-9

Rosemount 8732

SPECIAL CONDITIONS FOR SAFE USE (KEM 07.0038X):

If the Rosemount 8732 Flow Transmitter is used integrally with the Rosemount 8705 or 8711

Sensors, it shall be assured that the mechanical contact areas of the Sensor and Flow

Transmitter comply with the requirements for flat joints according to standard EN/IEC 60079-1

clause 5.2.

The relation between ambient temperature, process temperature, and temperature class is to be

taken from Table B-8 on page B-13

The electrical data is to be taken from Table B-7 on page B-12

If the Rosemount 8732 Flow Transmitter is used integrally with the Junction Box, it shall be

assured that the mechanical contact areas of the Junction Box and Flow Transmitter comply with

the requirements for flanged joints according to standard EN/IEC 60079-1 clause 5.2.

INSTALLATION INSTRUCTIONS:

The cable and conduit entry devices and blanking elements shall be of a certified flameproof type,

suitable for the conditions of use and correctly installed. With the use of conduit, a certified

stopping box shall be provided immediately to the entrance of the enclosure.

N7 IECEx Type n

8712D - Certificate No: IECEx BAS 07.0036X

EEx nA nL IIC T4 (Ta = -50 °C to + 60 °C)

V

max

= 42 V DC

8732 - Certificate No: IECEx BAS 07.0062X

Ex nA nL IIC T4 (Ta = -50 °C to + 60 °C)

V

max

= 42 V DC

Remote Junction Box

8732 - Certificate No.: KEM 07.0038X

IECEx Ex e

(1)

T6 (Ta = -50 °C to + 60 °C)

When installed per drawing 08732-1060

After de-energizing, wait 10 minutes before opening cover

(1)

IIC for E7

IIB for EF

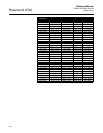

Table B-6. Sensor Approval

Information

Approval

Codes

Rosemount 8705 Sensor Rosemount 8707 Sensor Rosemount 8711 Sensor

Rosemount 8721

Sensors

For

Non-flammable

Fluids

For

Flammable

Fluids

For

Non-flammable

Fluids

For

Flammable

Fluids

For

Non-flammable

Fluids

For

Flammable

Fluids

For

Non-flammable

Fluids

NA • •

N0 • • •

ND•••••• •

N1 • • • •

N5••••••

N7 • • • •

ND • • • •

NF • • • •

E1 • • • •

E5

(1)

(1) Available in line sizes up to 8 in. (200 mm) only.

• • • •

KD

(2)

(2) Refer to Table B-8 on page B-13 for relation between ambient temperature, process

temperature, and temperature class.

••