6. ASSEMBLY

BAS-311G, BAS-326G

70

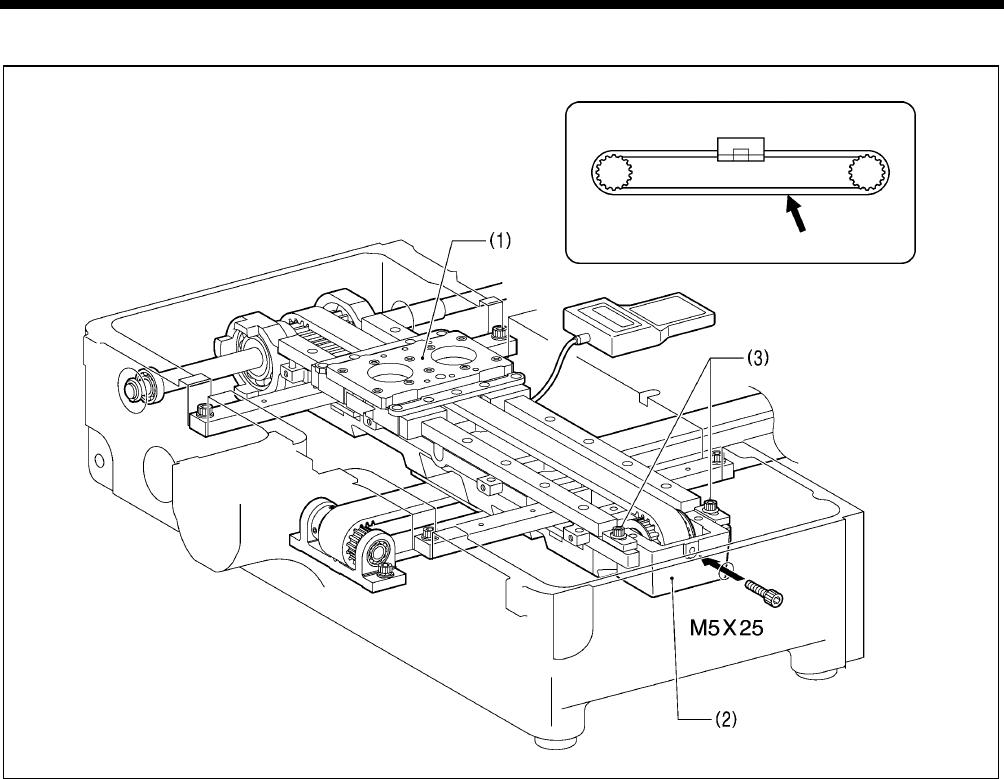

<X-GT belt tension adjustment>

1. Move the X feed bracket (1) so that it is in the middle of the sewing area in the Y direction and at the left edge of the

sewing area in the X direction.

2. Loosen the two bolts (3) of the X-pulley bracket (2), and then provisionally tighten them at 19.6 mN·m.

3. Pass the M5x25 screw through the countersunk hole in the side of the bed and screw it into the tap hold in the X-pulley

bracket (2). Then adjust the belt tension to the following value.

[For a new belt: 290 – 330 N; For a reused belt: 220 – 250 N]

4. Tighten the two bolts (3), and then remove the M5x25 screw.

5. Measure the belt tension once more and check that it is at the following value.

[For a new belt: 400 – 440 N; For a reused belt: 320 – 350 N]

* Be sure to use a belt tension gauge to measure the belt tension, and measure from the bottom of the belt.

* The belt tension gauge should be set to measure a unit weight of 0.04 kg/m, a belt width of 30 mm and a span length of

370 mm.

* The recommended belt tension gauge to use is the Dr. TENSION TYPE-ll manufactured by MITSUBOSHI BELTING

LTD.

5183Q

Measurement position