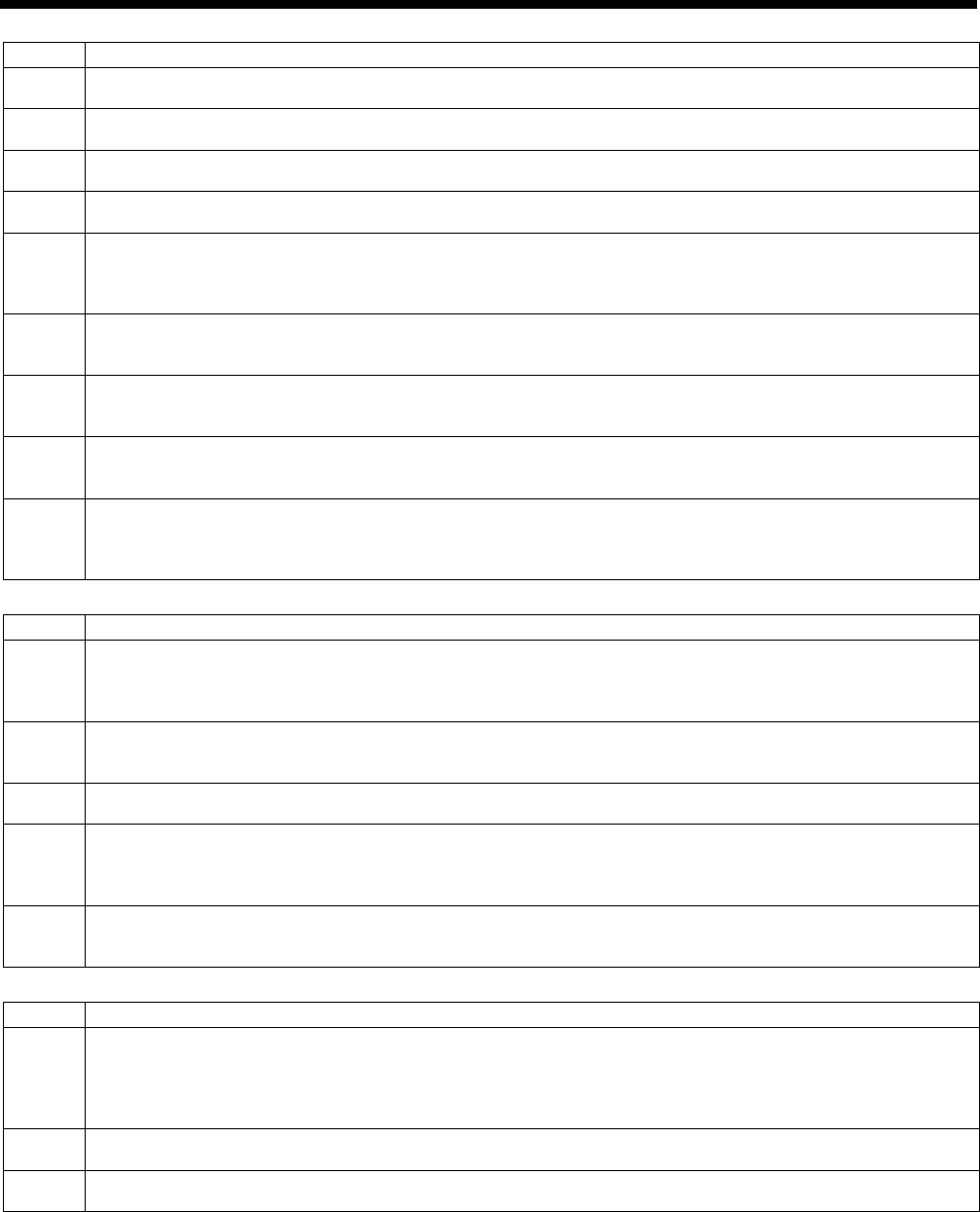

9. TABLE OF ERROR CODES

BAS-311G, BAS-326G

138

Upper shaft motor-related errors

Code

Cause and remedy

E110

Needle up stop position error.

Turn the machine pulley until the point where the error display disappears.

E111

Upper shaft did not stop at the needle up stop position when the sewing machine stopped.

Turn the machine pulley until the point where the error display disappears.

E120

Needle drop signal could not be detected.

Turn off the power, and then check the synchronizer connection.

E121

Thread trimming was not completed.

Turn off the power, and then check if the cutting edges of the fixed knife and movable knife are damaged or worn.

E130

Sewing machine motor stopped due to a problem, or synchronizer is faulty.

Turn off the power, and then turn the machine pulley and check if the sewing machine has locked up.

Check that connectors P4 and P5 on the power supply motor P.C. board are properly connected.

Check if the fuse (F1) is blown.

E131

Synchronizer is faulty.

Turn off the power, and then check that connector P5 on the power supply motor P. C. board is properly

connected.

E132

Problem detected with sewing machine motor operation.

Turn off the power, and then check that connector P4 on the power supply motor P. C. board is properly

connected.

E133

Sewing machine motor stopping position is incorrect.

Turn off the power, and then check that connector P5 on the power supply motor P. C. board is properly

connected.

E150

Sewing machine motor is overheating, or temperature sensor is faulty.

Turn off the power, and then check the sewing machine motor.

(When sewing data with a small number of stitches (15 stitches or less) is sewn repeatedly (short cycle

operation), the upper shaft motor may overheat and the “E150” error code may be generated.)

Feed mechanism-related errors

Code

Cause and remedy

E200

X-feed motor home position cannot be detected.

Problem with X -feed motor or poor X home position sensor connection.

Turn off the power, and then check that connector P10 on the PMD P.C. board and connector P20 on the main

P.C. board are properly connected.

E201

X-feed motor stopped due to a problem.

Turn off the power, and then check if there are any problems in the X-feed direction.

Check if the fuse (F2) is blown.

E202

Problem with X-feed motor or Y-feed motor home position adjustment data.

Re-adjust the home position.

E210

Y-feed motor home position cannot be detected.

Problem with Y-feed motor or poor Y home position sensor connection.

Turn off the power, and then check that connector P8 on the PMD P.C. board and connector P4 on the main P.C.

board are properly connected.

E211

Y-feed motor stopped due to a problem.

Turn off the power, and then check if there are any problems in the Y-feed direction.

Check if the fuse (F2) is blown.

Work clamp-related errors

Code

Cause and remedy

E300

Work clamp home position cannot be detected.

Problem with work clamp motor or poor work clamp home position sensor connection.

Turn off the power, and then check that connector P3 on the PMD P.C. board and connector P5 on the main P.C.

board are properly connected.

Check if the fuse (F2) is blown.

E301

Work clamp raised or lowered position cannot be detected.

Turn off the power, and then check if there are any problems in the work clamp vertical direction.

E303

Problem with work clamp motor home position adjustment data.

Re-adjust the home position.