Instruction Manual

IM-106-880, Rev 1.0

January 2007

1-7

OCX 8800

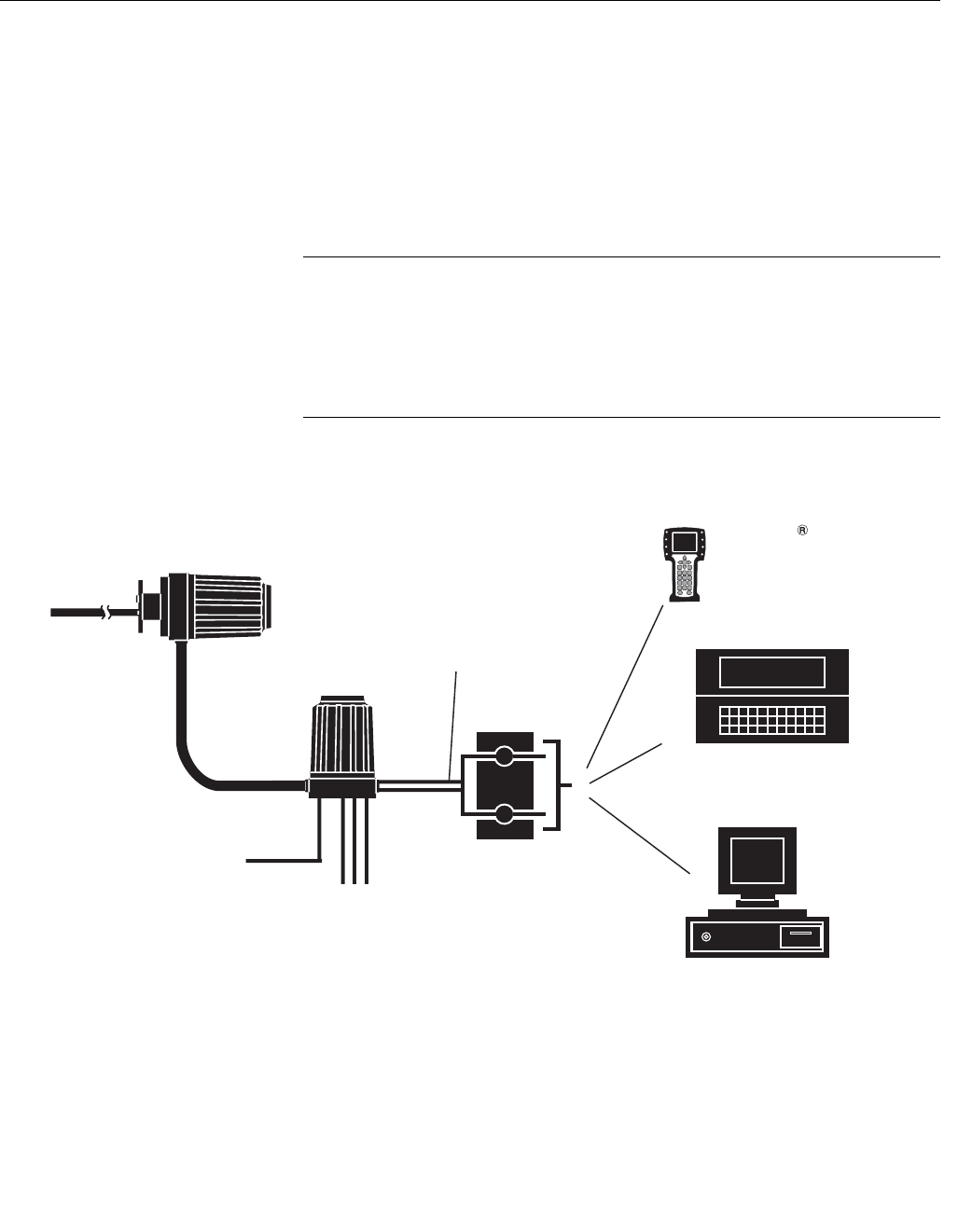

After verifying that you have all the components, select mounting locations

and determine how each component will be placed in terms of available line

voltage, ambient temperatures, environmental considerations, convenience,

and serviceability. Figure 1-3 shows a typical system wiring. Simplified

installations for the OCX 8800 are shown in Figure 1-4.

A source of instrument air is required at the OCX 8800 for reference air,

dilution air, and eductor air. Since the OCX 8800 is equipped with an in-place

calibration feature, provision should be made for connecting test gas tanks to

the OCX 8800 when it is to be calibrated.

NOTE

The electronics module is designed to meet NEMA 4 (IP66) and the electronic

components are rated to temperatures up to 185°F (85°C).

Retain packaging in which the unit arrived from the factory in case any

components are to be shipped to another site. This packaging has been

designed to protect the product.

Figure 1-3. OCX 8800 HART

Connections and AMS Application

37390065

4-20 mA Output

(Twisted Pairs)

Instrument

Air

3 calibration

gas lines by

customer

[300 ft (91 m) max.)

OCX 8800

Sensor Housing

HART

Model 275/375

Handheld

Communicator

Customer’s Laptop

with AMS

Termination in

Control Room

AMS

OCX 8800

Electronics Housing