50

REPLACING PNEUMATIC TIRES

AND TUBES - FRONT CASTERS AND

REAR WHEELS

WARNING

DO NOT use your power wheelchair unless it has

the proper tire pressure (p.s.i.). DO NOT overinflate

the tires. Failure to follow these suggestions may

cause the tire to explode and cause bodily harm.

If tires are pneumatic, replacement of tire or tube

MUST be performed by an Invacare dealer or

qualified technician.

NOTE: If front casters or rear wheels are pneumatic, un-

der-inflation causes excessive wear which results in poor

performance of the tires.

INSTALLING/REPLACING REAR

WHEEL ASSEMBLIES (FIGURES 5

AND 6)

WARNING

NEVER use a locking tab washer more than once.

ALWAYS use a NEW locking tab washer when in-

stalling the rear wheels.

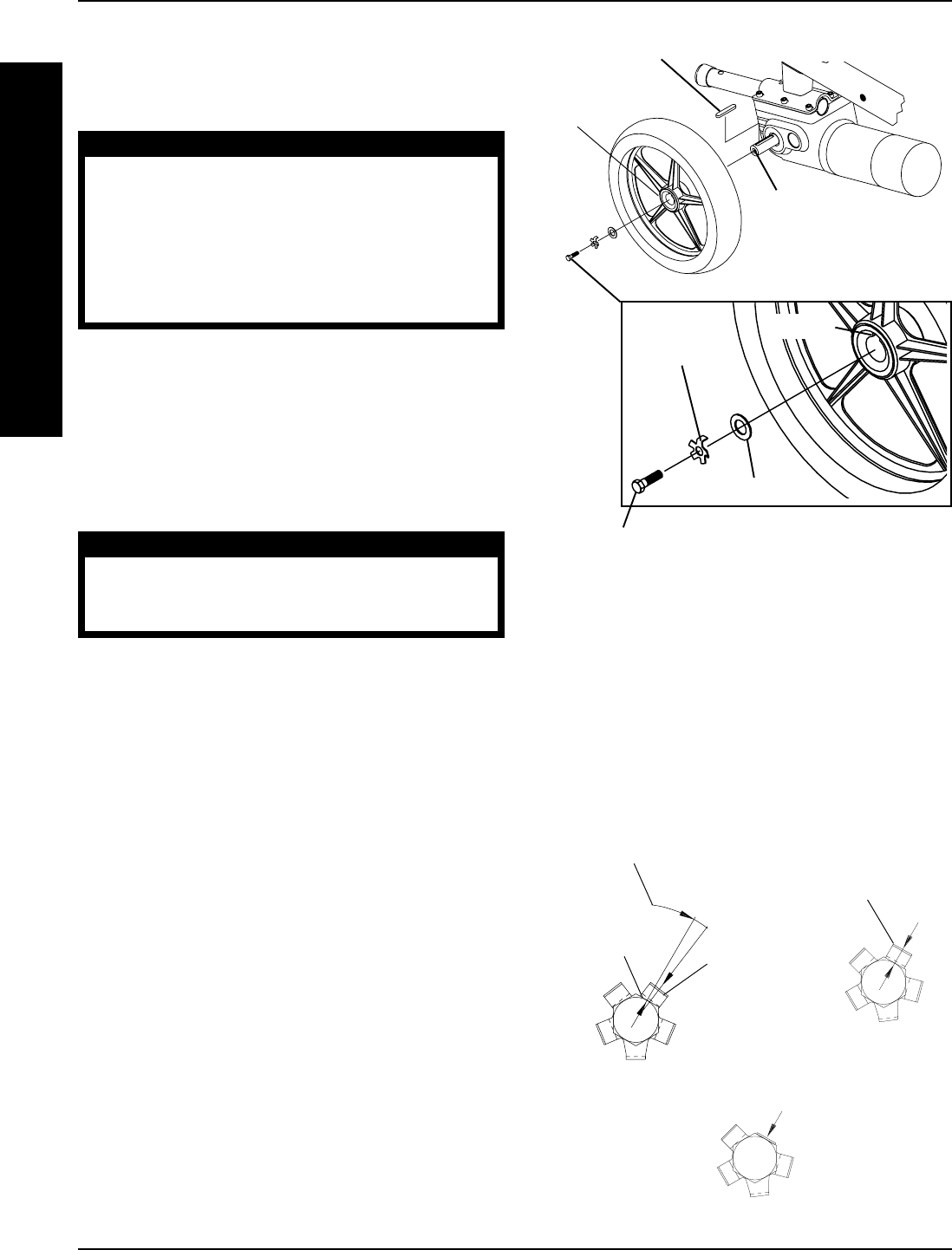

1. Remove the hex screw, lockwasher and washer that

secure the existing rear wheel assembly to the wheel

hub assembly.

2. Use a wheel puller to remove the existing rear wheel

assembly from the motor drive shaft.

NOTE: The keystock in the wheel hub MUST lineup with

the cutout in the gearbox drive shaft.

3. Install the new/existing rear wheel onto the motor drive

shaft. Make sure the chamfered side of the wheel

hub is pointing away from the wheelchair.

4. Install washer onto motor drive shaft.

5. Install the NEW locking tab washer onto the motor

drive shaft. Make sure the locking tab is in line with

the keyway of the rear wheel.

6. Apply Loctite 242 to the hex screw.

7. Install the hex screw. Use a torque wrench only and

torque to 90-inch pounds.

8. Examine the head of the hex screw and the locking

tab washer. Make sure one (1) of the tabs on the

locking tab washer is parallel with one (1) of the flats

on the head of the hex screw.

Motor

Driveshaft

Washer

Locking Tab

Washer

Keyway

Keystock

Chamfered

Side of

Wheel Hub

Hex Screw (Apply Loctite 242 and use a Torque

Wrench only to Torque to 90-inch pounds)

FIGURE 5 - INSTALLING/REPLACING

REAR WHEEL ASSEMBLIES

Flat on Head

of Hex Screw

Locking

Tab

9. If one (1) of the tabs on the locking tab washer is

NOT parallel with one (1) of the flats on the head of

the hex screw (FIGURE 6), TIGHTEN the hex screw

until the closest flat and locking tab are parallel.

TIGHTEN Hex Screw if

Locking Tab is not Parallel

with Flat on Head

(STEP 9)

Locking Tab Parallel

with Flat on Head of

Hex Screw

(STEP 9)

Bend Tab up tight against Flat on

Head of Hex Screw

(STEP 10)

FIGURE 6 - LOCKING TABS

W

H

E

E

L

S

/

A

N

T

I

-

T

I

P

P

E

R

WHEELS/ANTI-TIPPERPROCEDURE 10